Sputtering coating method for high-shielding thin-film against electromagnetic interference on plastic matrix

An anti-electromagnetic interference, plastic substrate technology, applied in the direction of sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of plastic deformation, shielding effect can not reach 70dB, low production efficiency, etc., to reduce Unit impedance, enhanced anti-electromagnetic interference effect, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

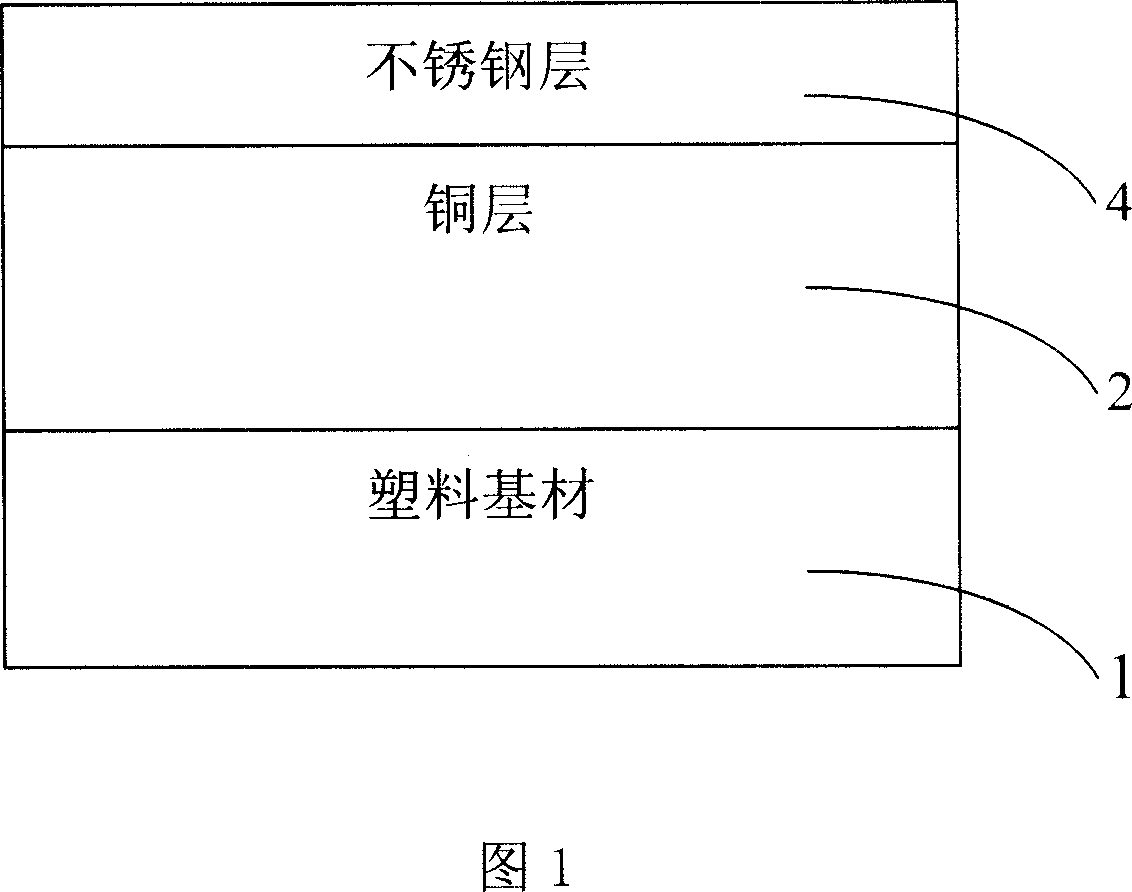

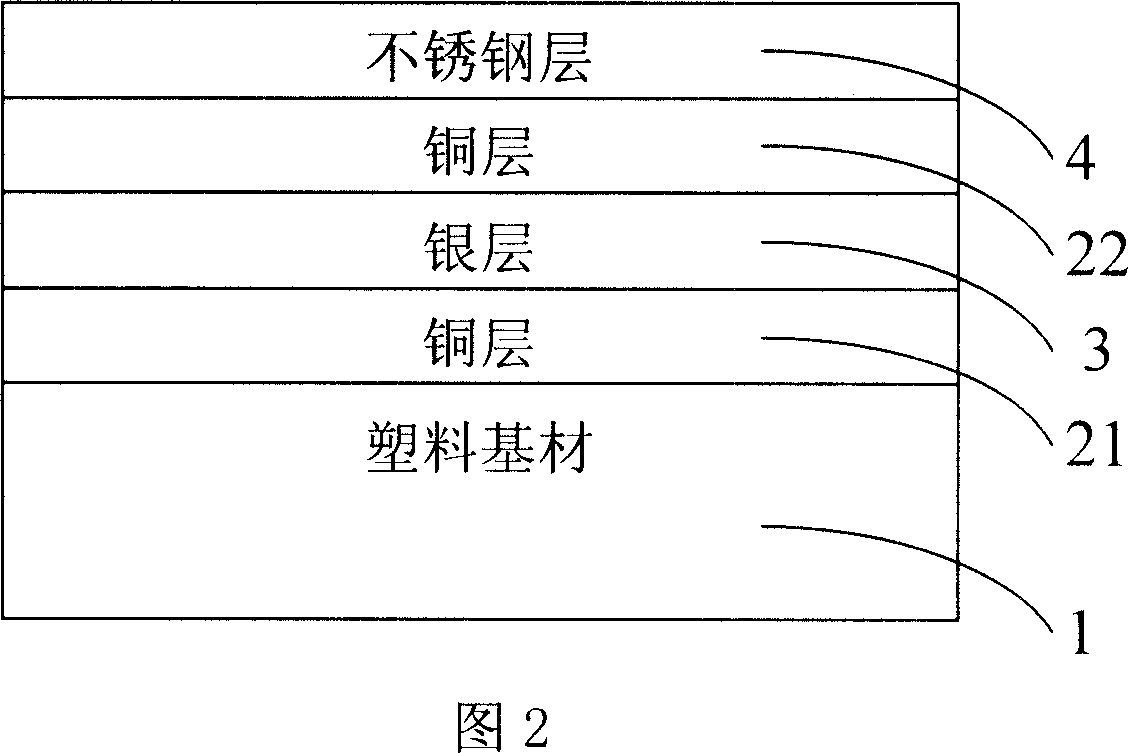

[0021] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0022] As shown in Figure 2, the sputtering method of plating high shielding anti-electromagnetic interference film on the plastic substrate of the present invention comprises the steps:

[0023] In the sandblasting treatment step, the surface of the plastic substrate 1 is sandblasted with brown corundum sand grains or white corundum sand grains;

[0024] In the cleaning step, the surface of the plastic substrate 1 that has been sandblasted is cleaned with ultrasonic waves, and the sand grains on the surface of the plastic substrate 1 are washed away;

[0025] In the film coating step, a layer of copper film 21 is plated on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com