Roll harnessing equipment and rolling method

A jig and rounding technology, applied in the direction of manufacturing tools, clamping, support, etc., can solve the problems of uneven distribution of UV glue, loose dislocation, inconsistent rounding conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

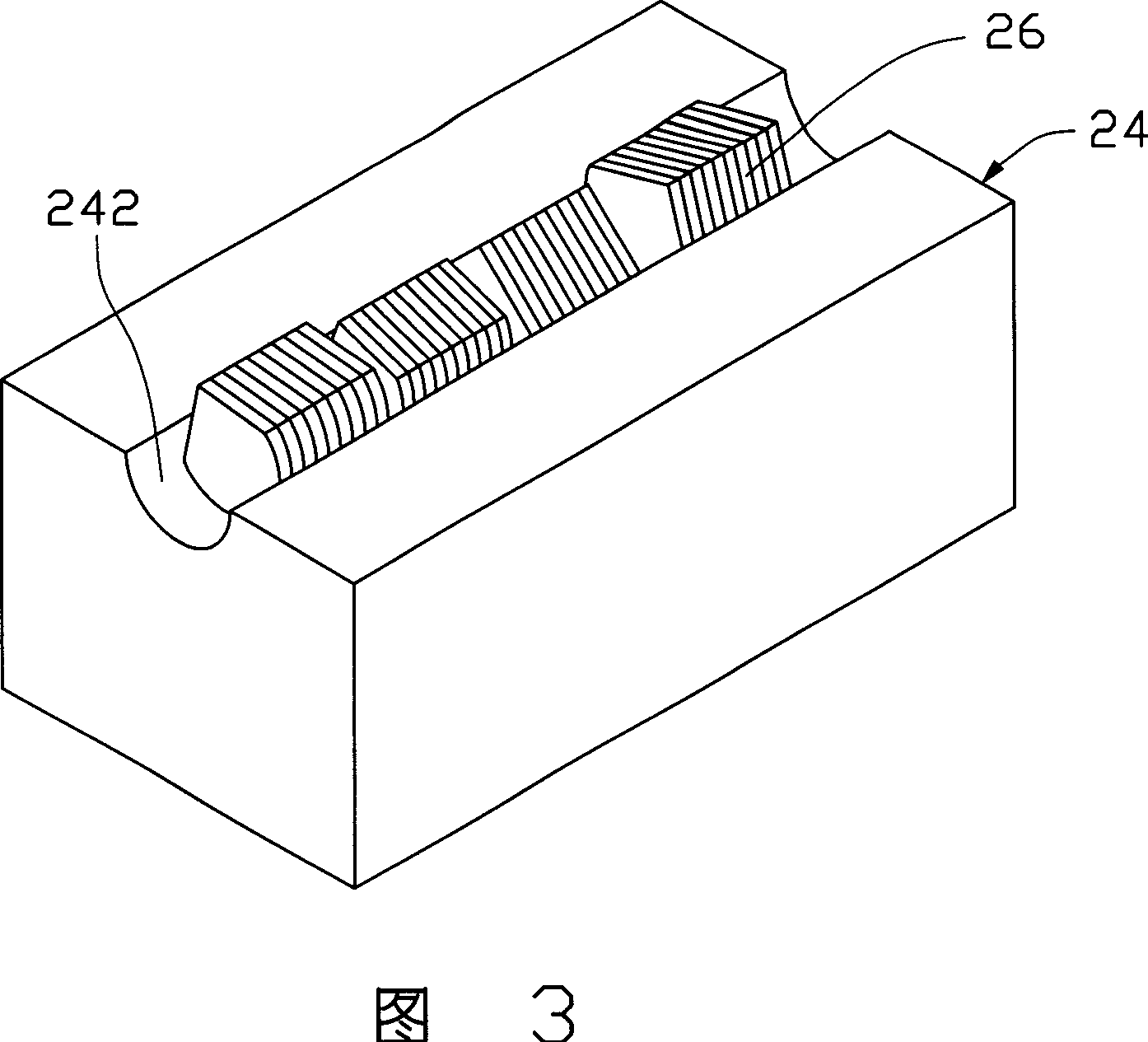

[0024] Referring to FIG. 4 and FIG. 5 , a preferred embodiment of the rounding jig of the present invention includes a first jig 42 and a second jig 44 . Please refer to FIG. 6 , the rounding jig is used for rounding the lens 46 of the camera lens.

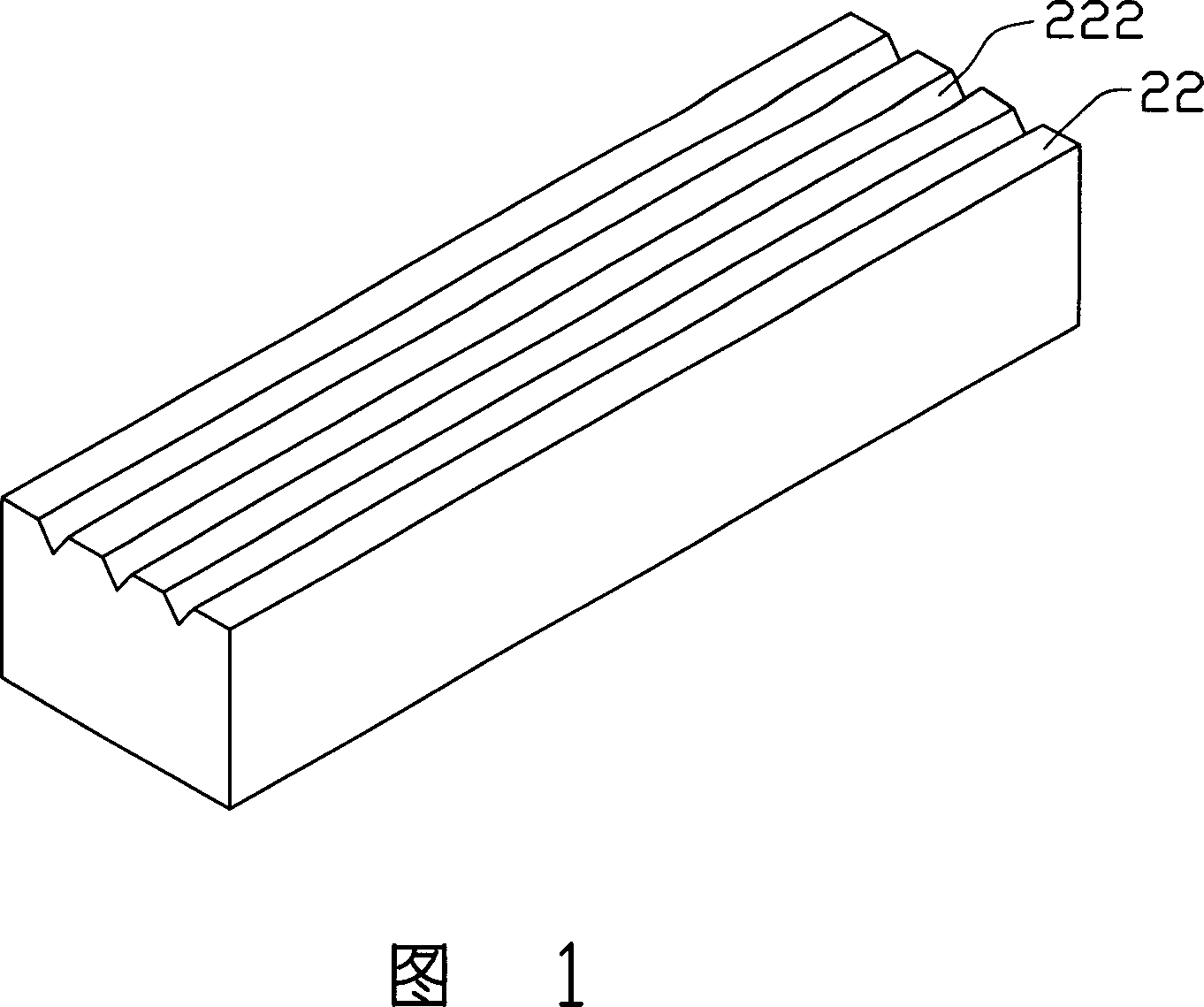

[0025] The first jig 42 is in the shape of a cuboid and includes a first surface 420. A groove 422 is provided on the first surface 420. A plurality of parallel grooves 422 can also be provided on the first surface 420, thereby Multiple groups of lenses 46 can be rounded at the same time. This embodiment is described by taking a groove 422 as an example. The cross-sectional shape of the groove 422 is funnel-shaped, that is, a part of the groove 422 is a square groove, and a part is a trapezoidal groove. 424 , the angle between the two slopes 424 and the first surface 420 of the first jig 42 is 45°.

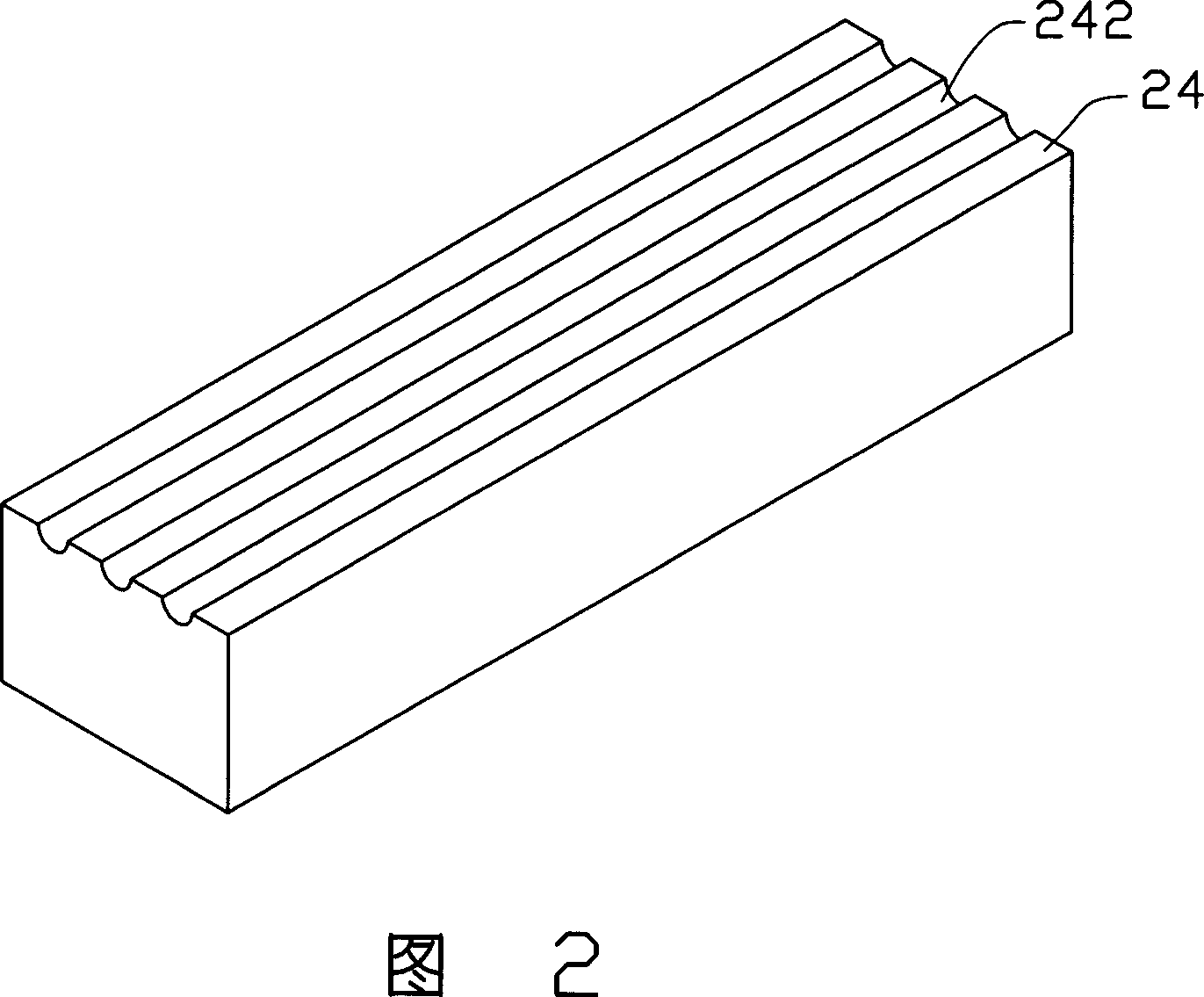

[0026] The second jig 44 is in the shape of a cuboid, and includes a second surface 440, on which a semicircular groove 442 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com