Tea cream, its production and use

A technology of tea cream and tea leaves, which is applied in the field of tea products and its preparation, can solve the problems of easy, quick and scientific drinking, unsuitable storage of tea leaves, etc., achieve clear and bright color, pure but not blunt aroma, and reduce inhalation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

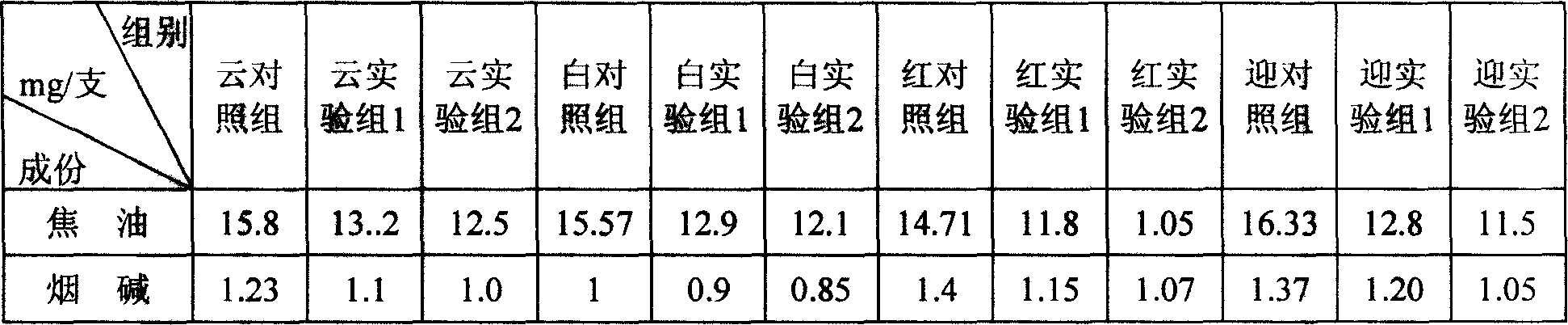

Image

Examples

Embodiment 1

[0050]a. Take 1000kg of semi-finished tea leaves, 0.1kg of sucrose; 0.1kg of edible salt;

[0051] b. After cleaning the tea leaves, add 3000kg of boiling water, keep boiling slightly, and decoct twice, the first time for 8-10 minutes, and the second time for 12-15 minutes; combine the filtrates, filter, and concentrate the filtrates. The density is 1.10 (measured at 60°C), and the tea juice is black and bright in color. When the tea fragrance is flowing out, boil it with a slow fire until it becomes an extract with a relative density of 1.40-1.50 (measured at 60°C). When simmering, stir counterclockwise at a constant speed, and the stirring speed is 1 to 2 revolutions / second. c. Put edible salt and sucrose in a container and bake until the color is slightly yellow, then grind it into fine powder, spread it evenly in the extract in step b in a slow fire, stir counterclockwise, until the paste becomes golden yellow and silky, change Keep stirring over low heat until the paste ...

Embodiment 2

[0053] a, take 800kg of old tea leaves, 0.5kg of sucrose; 0.3kg of edible salt;

[0054] b. After cleaning the tea leaves, add 4000kg of boiling water, keep slightly boiling, and decoct twice, the first time for 8-10 minutes, and the second time for 12-15 minutes; combine the filtrates, filter, and the filtrates are concentrated under reduced pressure. Concentrate to make an extract whose relative density is 11.50 (measured at 50°C), and move it to a container on a slow fire;

[0055] c. Put edible salt and sucrose in a container and bake until the color is slightly yellow, then grind it into fine powder, spread it evenly in the extract in step b in a slow fire, stir counterclockwise, until the paste becomes golden yellow and silky, change Keep stirring over low heat until the paste turns into golden flakes, then put it into a mold while still hot, and let it cool naturally. The paste amount is 160kg.

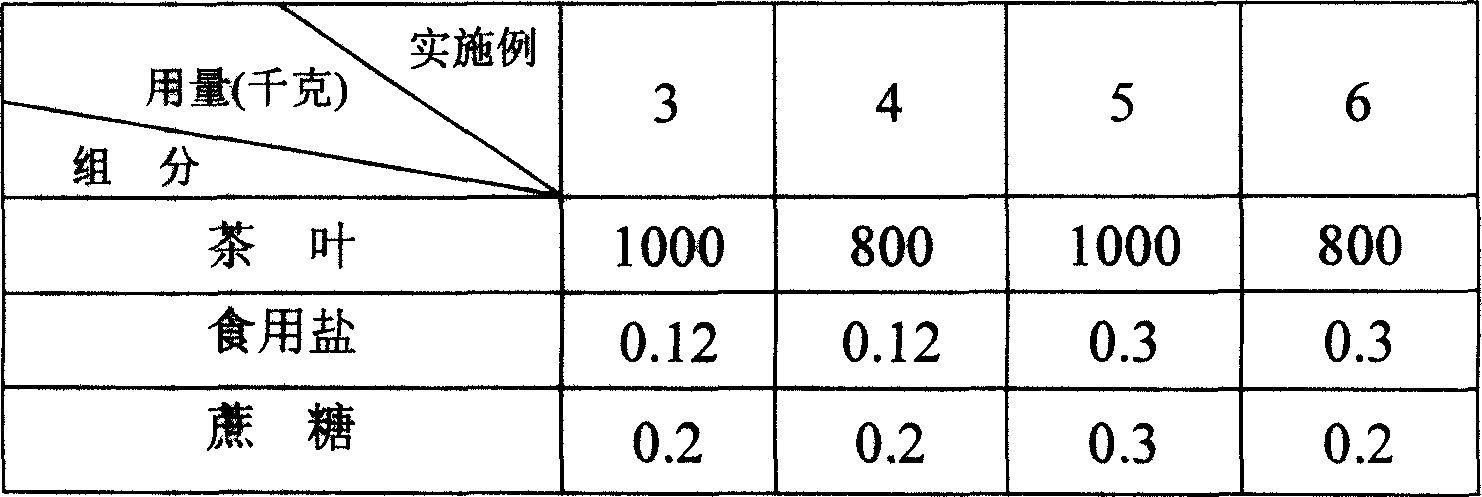

[0056] The following examples are only different in the amount of raw ma...

Embodiment 3-6

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com