Discontinuous mode PFC controller with energy-saving modulator and its operating method

A controller and mode technology, applied in the direction of climate sustainability, output power conversion device, irreversible AC power input conversion to DC power output, etc., can solve the problem that power converters are difficult to meet energy saving requirements, switching transistor switching loss buffering Inductor power consumption, increased loss of inductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

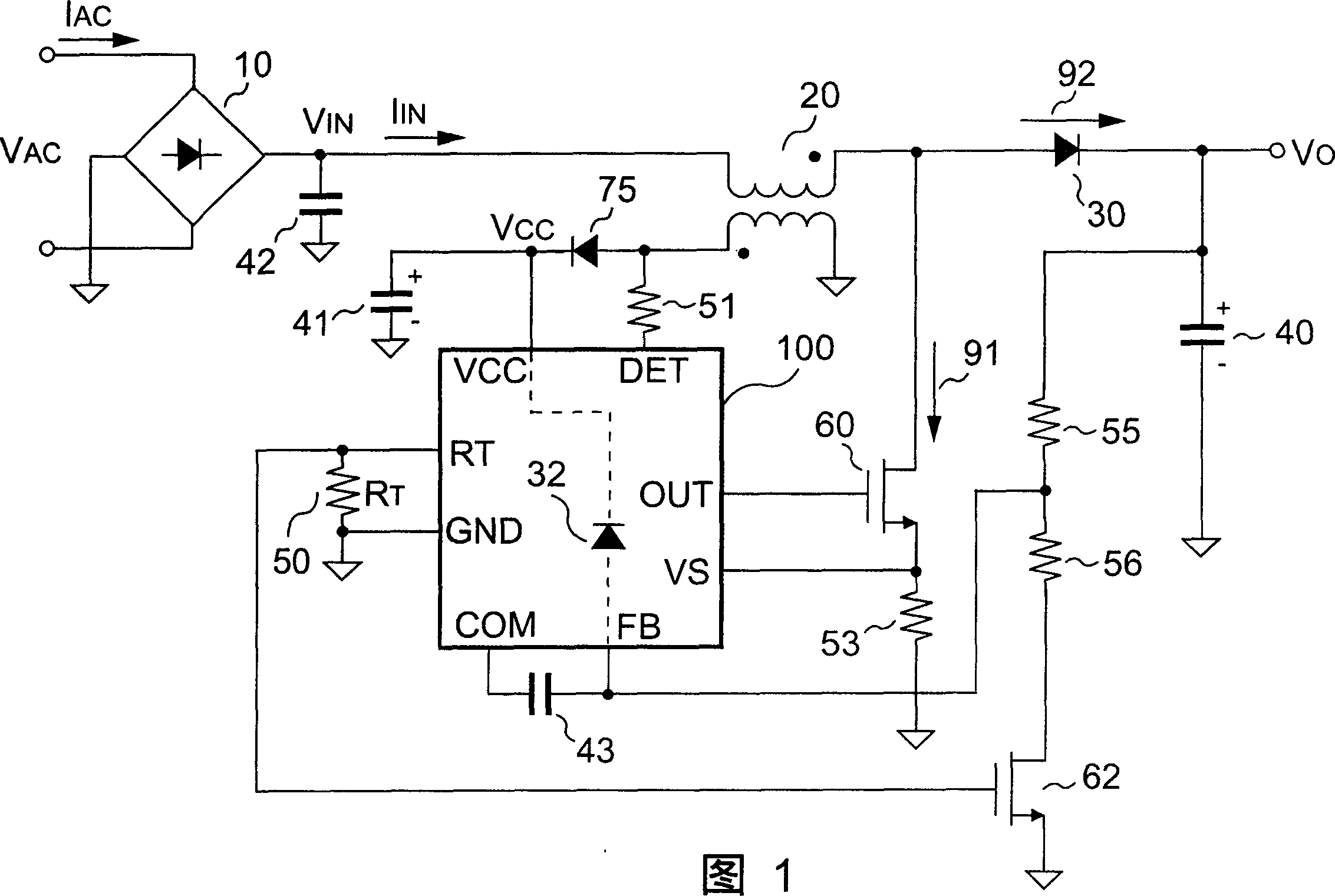

[0017] FIG. 1 is a schematic diagram of a discontinuous mode power factor correction (PFC) converter according to a preferred embodiment of the present invention. The PFC converter includes a bridge 10 , an inductor 20 , a rectifier 30 and a capacitor 40 . For feedback operation, the PFC converter further includes a controller 100 ; capacitors 41 and 43 ; resistors 50 , 51 and 53 ; a voltage divider including resistors 55 and 56 ; transistors 60 and 62 and a diode 75 . Through the PFC converter, the alternating current (AC) line input is converted into direct current (DC) output V O , where switching current 91 switches AC via input inductor 20 , rectifier 30 and capacitor 40 to control energy. The purpose of the PFC converter is to convert the AC line input current I AC The waveform control is sinusoidal and maintains I AC phase with the AC line input voltage V AC same. rectified via bridge 10, V IN Always positive with respect to ground of the PFC converter.

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com