Integral-filled type plastic-coated steel twisted line

A technology of steel strand and filling type, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of high cost, insufficient corrosion resistance of steel strands, etc., and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

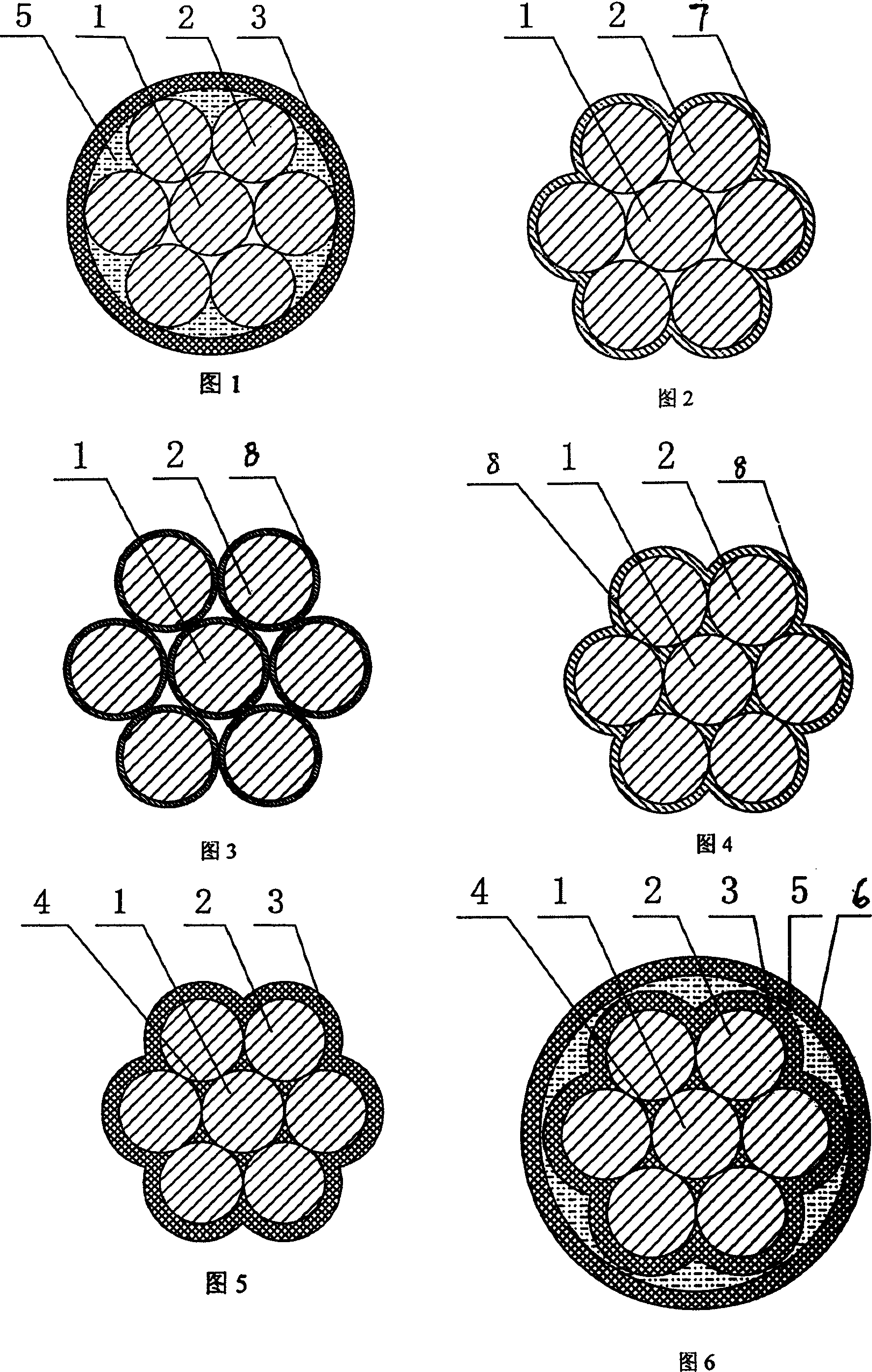

[0017] Example 1: Integral filled plastic-coated steel strand

[0018] As shown in Figure 5, a core wire 1 and multiple side wires 2 form a steel strand, and a layer of HDPE plastic anti-corrosion layer 3 is coated around the outer edge of the steel strand, and the thickness of the coating is 0.8mm-1.2mm . And the HDPE plastic anticorrosion layer 4 is also filled in the gap between the core wire 1 and each side wire 2 .

Embodiment 2

[0019] Embodiment 2: Integral filled plastic-coated steel strand filled with grease or paraffin

[0020] This kind of steel strand structure is as shown in Figure 6, is to coat the mixture 5 of grease or paraffin or grease and paraffin on the steel strand surface of coating HDPE plastic anticorrosion layer 3 described in embodiment 1, coats outside it again One layer of HDPE plastic anti-corrosion layer 6. The oil and paraffin can be mixed in any ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com