Antirust coating for Golf club head

A golf club head and anti-rust coating technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems such as the structure of the anti-rust coating is not dense enough, so as to improve the design margin, improve oxidation resistance, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

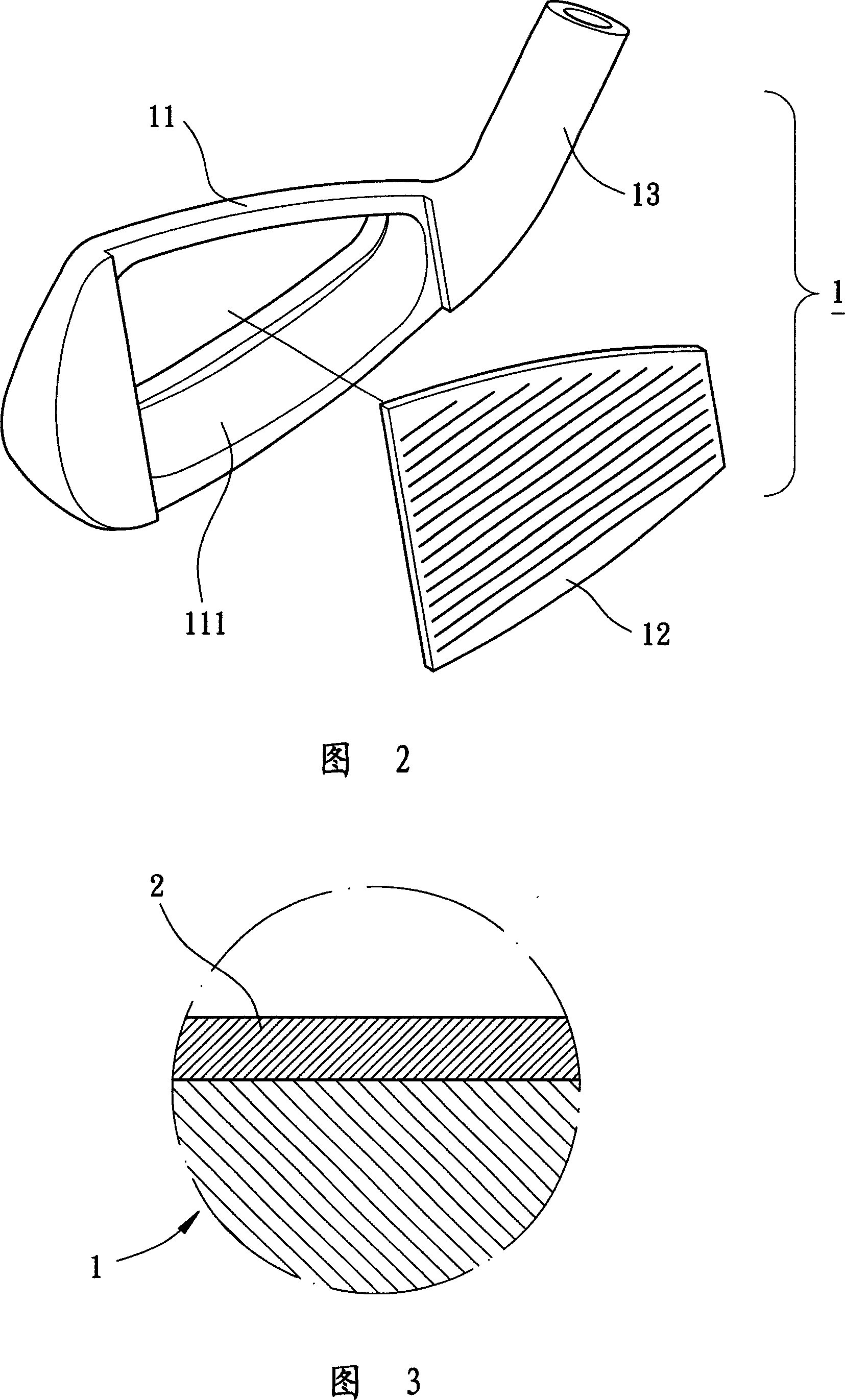

[0022] As shown in FIG. 1 , the first preferred embodiment of the present invention is a golf club head antirust coating applied to a wood-type golf club head 1 . The applicable component of the antirust coating is the club head body 11 , strike panel 12, sleeve neck 13, base plate 14, exterior trim plate 151 of counterweight 15, top plate 16, side plate (not shown in the figure) or back plate (not shown in the figure) etc.

[0023] As shown in Figure 2, the second preferred embodiment of the present invention is a golf club head anti-rust coating, which is applied to an iron golf club head 1. In addition to the listed components, it can also be the inner wall surface 111 of a deep hole [undercut, not shown in the figure] of the golf club head. The back [not shown] is formed together.

[0024] Please refer to shown in Fig. 3, the antirust coating 2 of the preferred embodiment of the present invention is made of iron metal with a density of 7.90g / cm 3 、Cobalt metal density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com