Wheat-straw biological clean pulping technology by black liquor bacterizing treatment

A technology of wheat straw and process, which is applied in the direction of fiber raw material treatment, cellulose raw material pulping, textile and paper making, etc., can solve the problems of large pollution and high COD production, reduce processing and operating costs, and improve pulp quality and improve The effect of ring crush strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

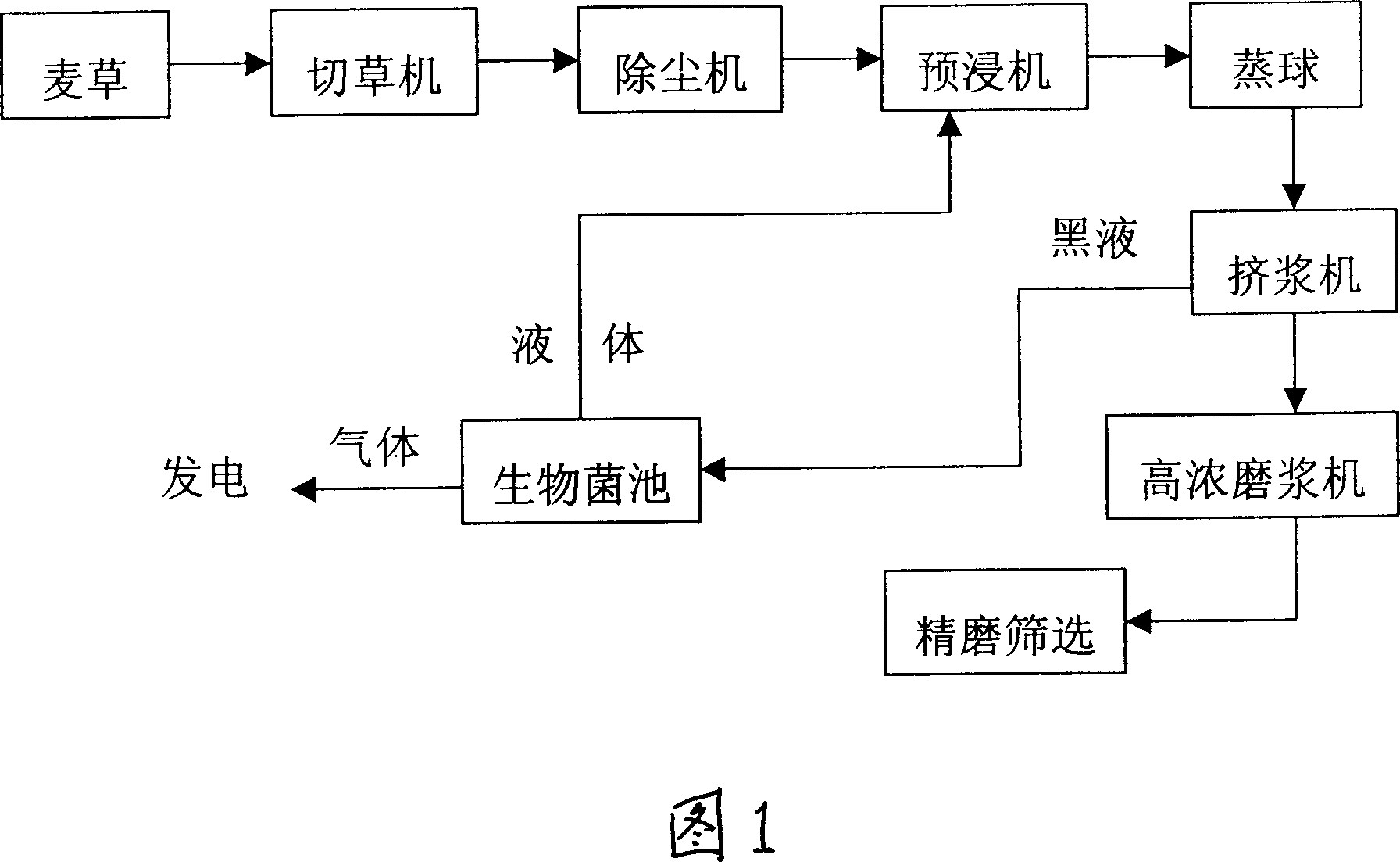

[0017] Firstly, the raw material of wheat straw (straw class) is cut short, and the length of the straw is 2-3cm, and then dust is removed by horns to remove heavy impurities and prevent subsequent equipment from being damaged. The short-cut wheat straw raw material enters the prepreg machine, and at the same time, adds biological liquid according to a certain liquid ratio, and puts it into steaming balls; material. Run dry for 15 minutes; once the boost pressure rises to 0.2MPa; the pressure inside the steam ball must be reduced to zero when the steam is released; the second boost time is 40 minutes, rising to 0.6MPa; after 120 minutes of heat preservation, pour the material. After cooking, the slurry is processed through a squeezer and a high-consistency mill, and then enters a fine grinding and screening system. The black liquor from the pulping machine enters the biochemical bacteria pool.

[0018] At the beginning of the process, the original biological strains of metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com