Petrochemical effluent treating and reusing process

A petrochemical and treatment process technology, applied in the field of petrochemical sewage reuse treatment process, can solve the problems of ineffective removal of Fe and other metal ions, ineffective removal of suspended solids, and increased operating costs, so as to prolong the effective active time and occupy The effect of small floor area and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

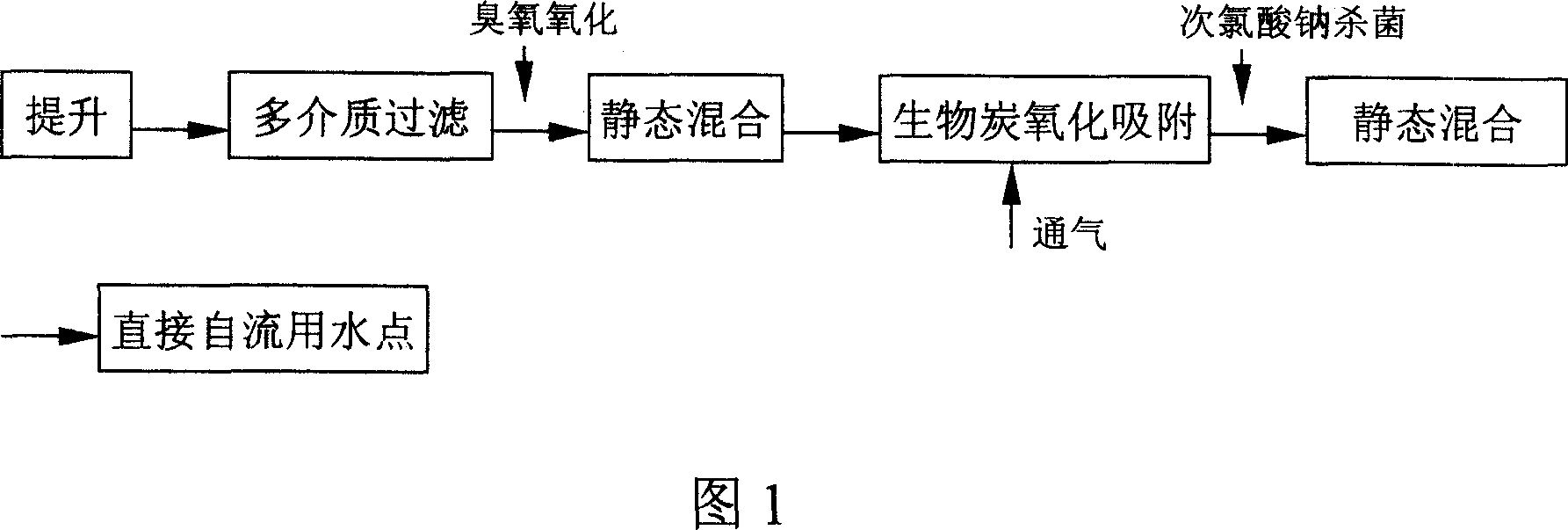

[0020] Example: See Figures 1 and 2, the treated influent water is a refinery wastewater treated to COD cr 101mg / l, turbidity 16mg / l, oil 9.7mg / l, water temperature 15-40℃ pretreatment water. According to the flow chart in Figure 1: the incoming water is filtered through the multi-media pressure filter 1, and the filtered water is injected into the COD per gram cr 7.8mg / l ozone, fully mixed by a static tube mixer, and then put into a coal with typical adsorption value > 750mg / g, strength > 95%, moisture cr 37mg / l, removal rate 63%, turbidity 3.3mg / l, removal rate 79%, oil 4.1mg / l, removal rate 58%, no metal ions such as Fe were detected.

[0021] Among them, the pressure filter 1 is respectively placed with a 600mm layer of anthracite filter material with a particle size of 1-2mm from top to bottom; a 600mm layer of quartz sand filter material with a particle size of 1-1.2mm; The iron ore filter layer is 600mm, and the magnetite filter layer with a particle size of 0.5-1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com