Method of forming hydrophobic transparent film on the surface of different substrates

A technology for the surface of a substrate and a transparent film, which can be used in devices for coating liquids on the surface, paints containing biocides, antifouling/underwater coatings, etc. It is difficult to use glass coating and other problems to achieve the effect of good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

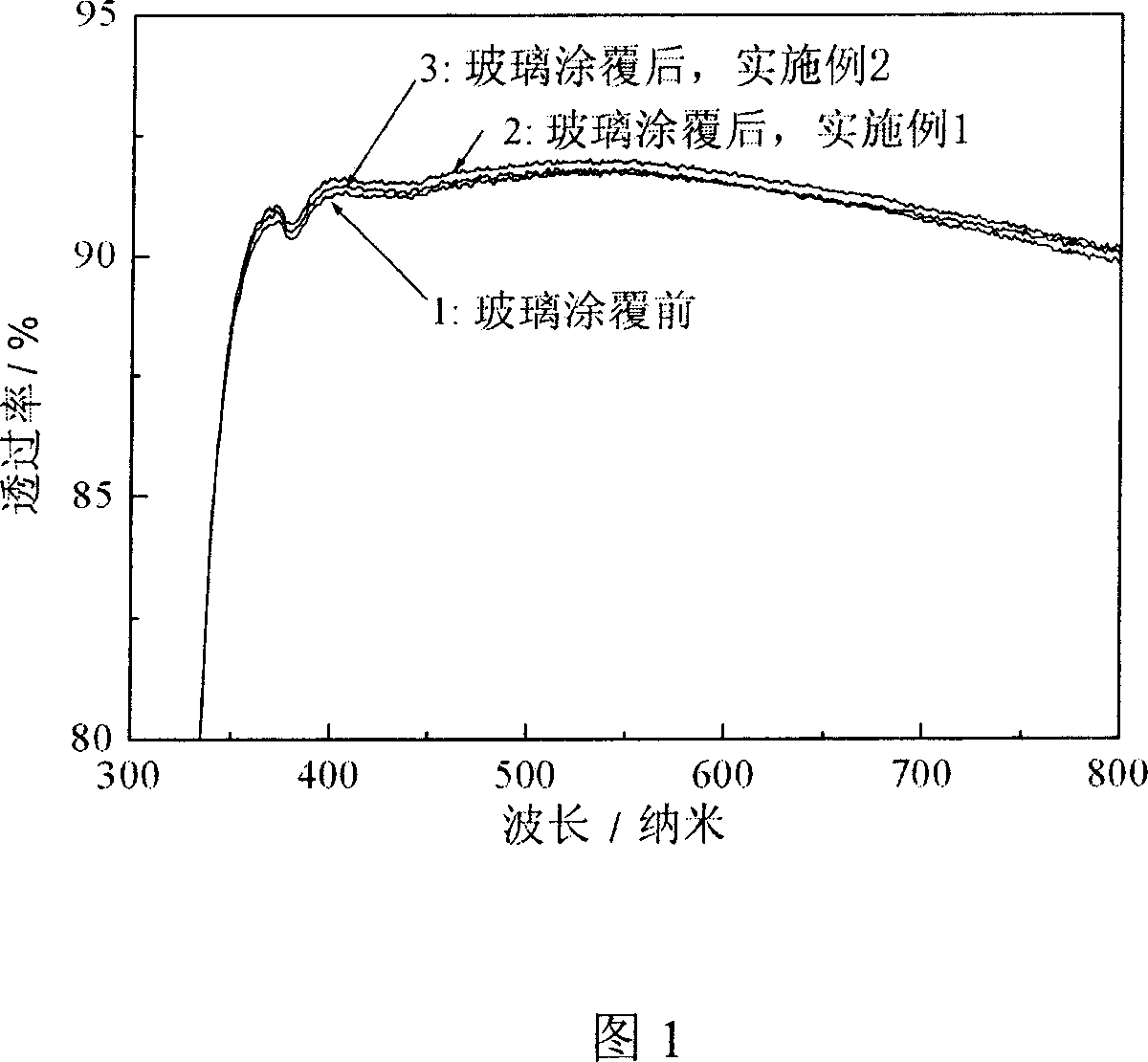

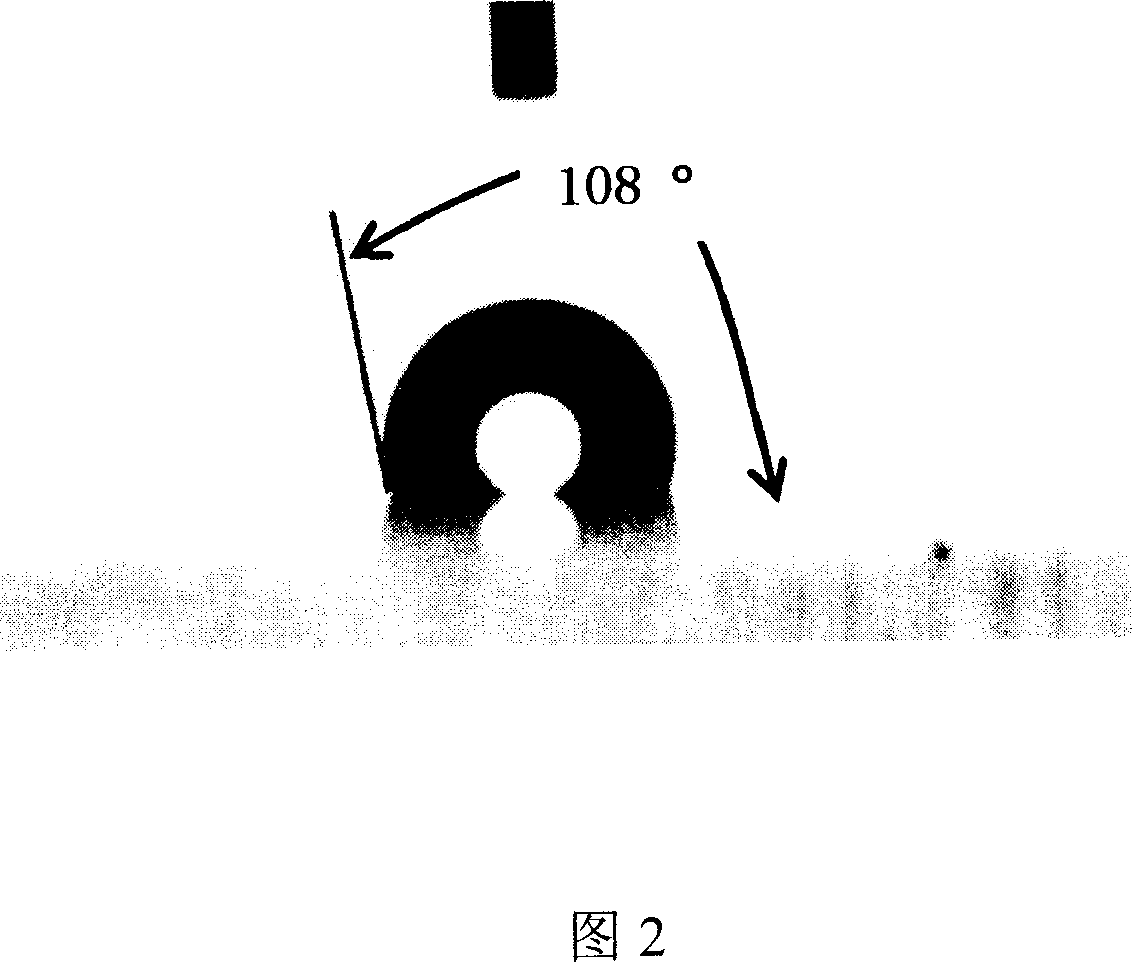

[0030] Weigh 10g tridecafluorooctyltriethoxysilane CF 3 (CF 2 ) 5 C 2 h 4 Si(OC 2 h 5 ) 3 and 5g tetraethyl orthosilicate (molecular formula Si(OC 2 h 5 ) 4 , was added to 82.2g of isopropanol, followed by 2.8g of 0.1M HNO 3 , refluxed at 40° C. for 12 hours to obtain hydroxylated fluorosilane containing silicon oxide nanoparticles, containing 10% fluorine silane (calculated as tridecafluorooctyltriethoxysilane). After cooling, it was diluted with isopropanol at a mass ratio of 1:5, so that the contained fluorosilane was 2% (based on tridecafluorooctyltriethoxysilane). Double-sided coating of glass at room temperature, the dosage is 15ml / m 2 . After wiping with a soft cloth, the contact angle was measured to be 108 degrees without heat treatment for 24 hours. 2 in Figure 1 shows the light transmittance curve of the glass after transparent coating of this liquid, and the transmittance of the glass after coating not only does not decrease, but also increases slightl...

Embodiment 2

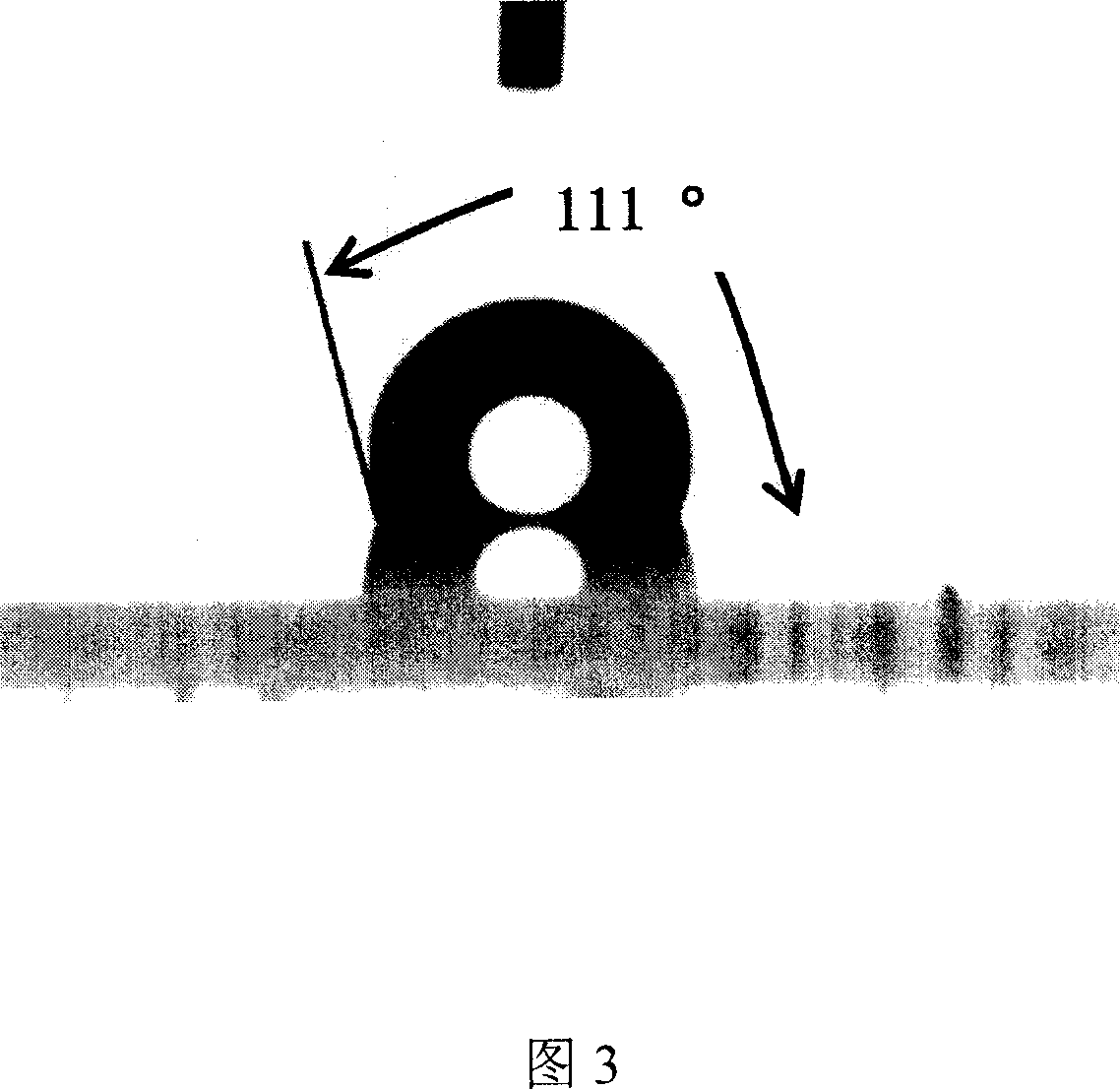

[0032] Weigh 15g tridecafluorooctyltriethoxysilane CF 3 (CF 2 )5C 2 h 4 Si(OC 2 h 5 ) 3 and 2g tetraethyl orthosilicate (molecular formula Si(OC 2 h 5 ) 4 , was added to 80.7g of isopropanol, then 2.3g of 0.1M HCl was added, and refluxed at 70°C for 0.5 hour to obtain a hydroxylated fluorosilane containing silica nanoparticles, 15% of fluorine-containing silane (as tridecafluorooctyltri Ethoxysilane meter). After cooling, it was diluted with isopropanol at a mass ratio of 1:10, so that the contained fluorosilane was 1.5% (based on tridecafluorooctyltriethoxysilane). The fluorosilane that gets 50g is that 1.5% (in tridecafluorooctyltriethoxysilane) solution is mixed with the isopropanol colloid dispersion liquid of 50g containing silicon oxide aerosol 1.0%, the fluorosilane after mixing is 0.75%, containing 0.5% silicon oxide. Double-sided coating of glass at room temperature, the dosage is 15ml / m 2 . After wiping with a soft cloth, the contact angle measured witho...

Embodiment 3

[0034] Dilute the commercial silica sol to contain 1.0% silicon oxide, the primary particle size of silicon oxide in it is about 10nm, and coat the paint surface at room temperature, the dosage is 20ml / m 2 . Wipe it evenly with a soft cloth, and apply diluted fluorosilane containing silica airgel after 15 minutes. The preparation is the same as in Example 2, wherein the fluorosilane contains 0.75% and the silica contains 0.5%. Coat the paint surface at room temperature, the dosage is 20ml / m 2 . After wiping with a soft cloth, the contact angle was measured to be 105 degrees in 24 hours. The measurement and calculation methods of the contact angle have been explained in the main text.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com