Prepn process of efficient visible light photocatalyst and photoelectric conversion and luminescent material TiOxNyCz

A technology of photocatalysts and luminescent materials, applied in chemical instruments and methods, physical/chemical process catalysts, circuits, etc., can solve the problems of unsuitability for large-scale industrial production, high cost of raw materials, complicated process, etc., and achieve good visible photocatalytic performance , short process, and strong photoluminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

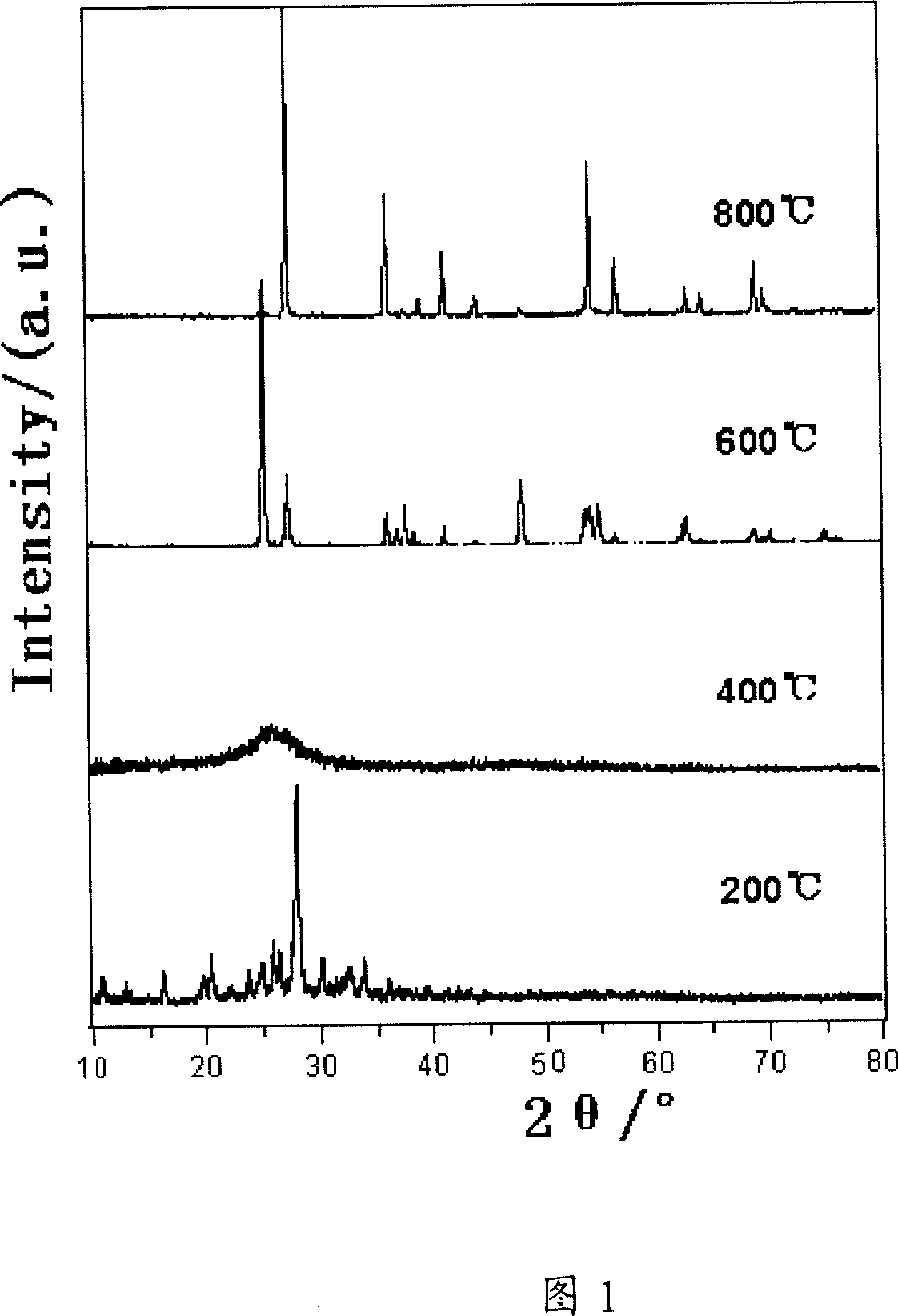

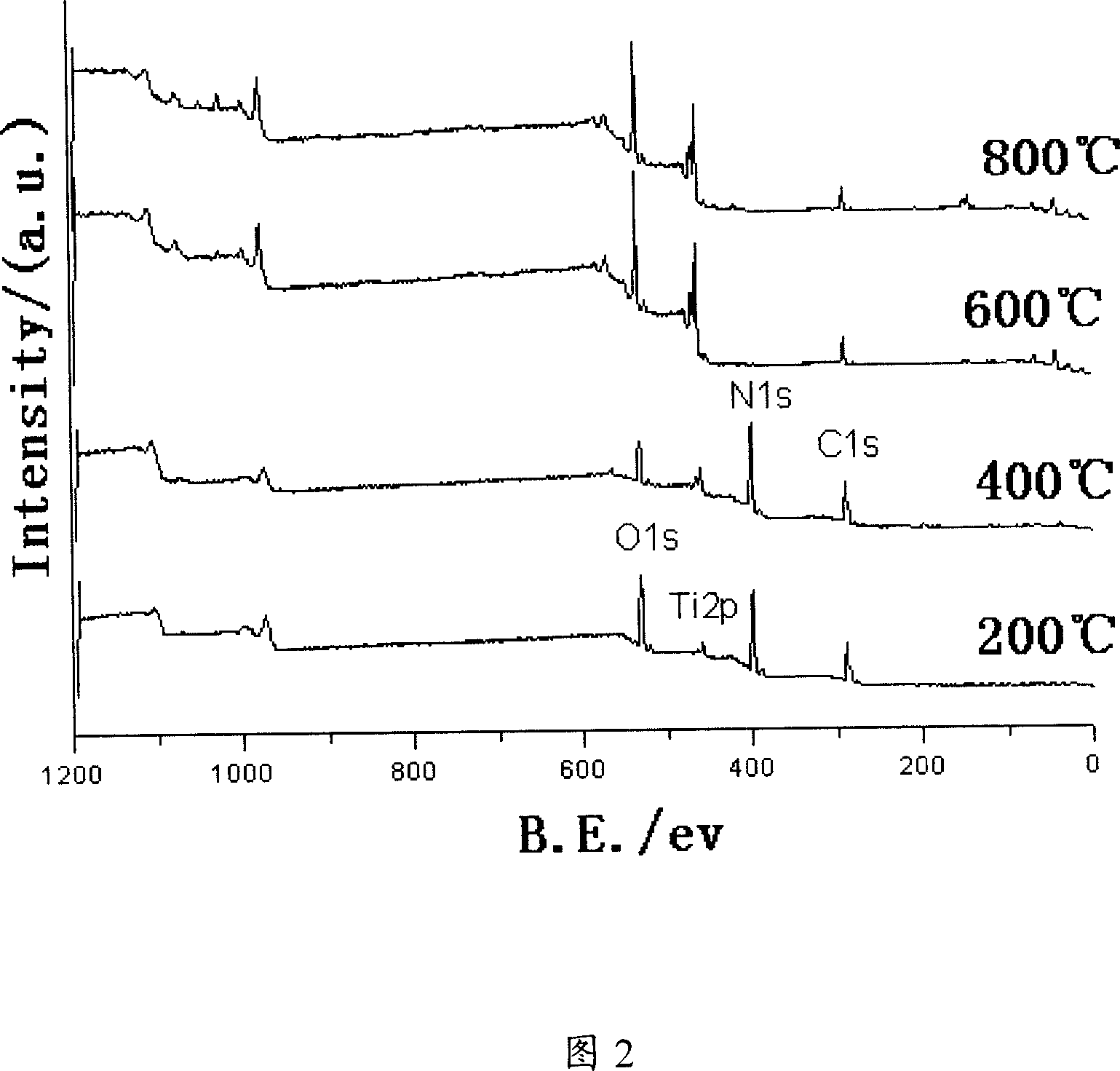

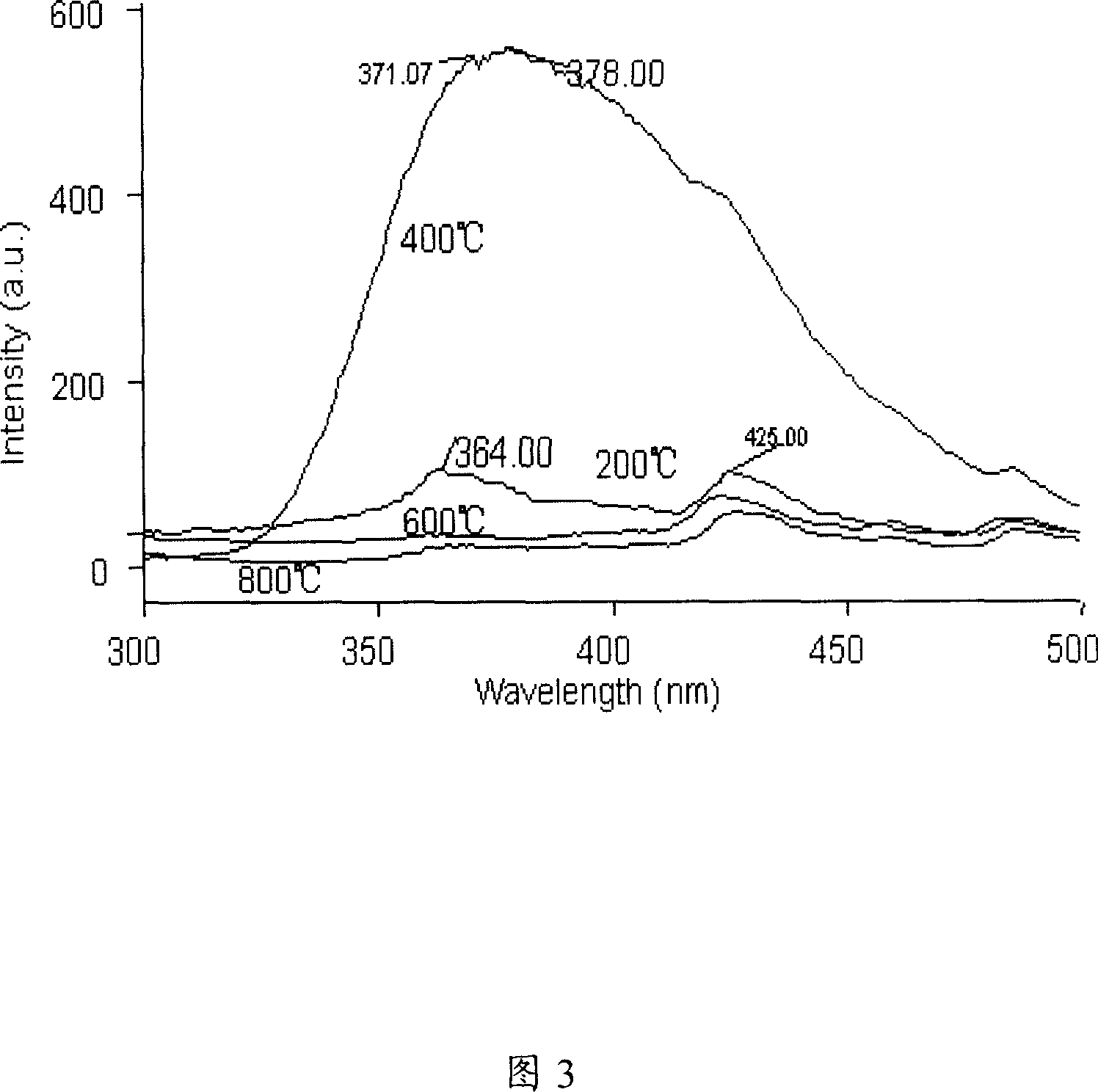

[0024] Alcoholyze 10mL of titanium tetrachloride with 60mL of methanol, heat to boiling at about 63°C, add 100g of urea, dissolve, cool, solidify, and calcinate in a muffle furnace at 200, 400, 600, and 800 degrees respectively to obtain the composition TiO with different compositions x N y C z powder.

[0025] Attached table is the element content of the sample under several burning temperatures of Example 1

[0026]

Embodiment 2

[0028] Hydrolyze 5mL of titanium tetrachloride with 10mL of water first, then add 100mL of methanol, heat to about 55°C, add 200g of urea, dissolve, cool, solidify, and calcinate in a muffle furnace at 200, 400, 600, and 800 degrees respectively , to get TiO x N y C z sample.

Embodiment 3

[0030] Alcoholyze 10 mL of titanium tetrachloride with 100 mL of methanol, heat to boiling, add 200 grams of urea, dissolve, cool, solidify, and calcinate in a muffle furnace at 300 degrees to obtain light yellow TiO x N y C z powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com