Manufacturing technique of low compression ratio high grade pipe line steel

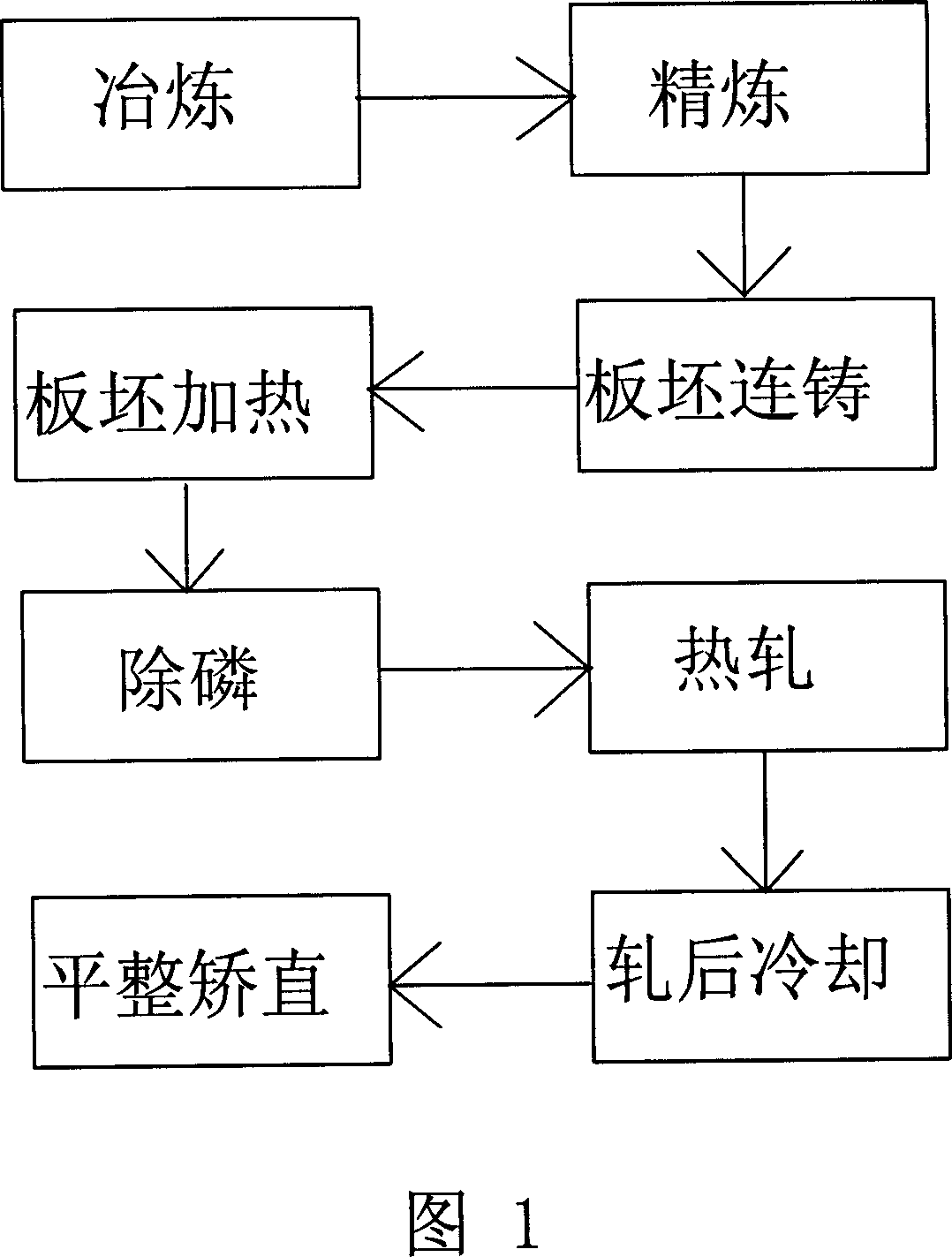

A technology with low compression ratio and production process, which is applied in the field of high-strength low-alloy steel production process, and can solve the problems of difficult production line and failure to produce thick-gauge pipeline steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is a specific production process of pipeline steel X70 with a compression ratio of 6.9. The selected process is suitable for the production of X70 pipeline steel in the steckel mill. The thickness of the billet is 150mm, the thickness of the finished plate is 21-21.5mm, the range of compression ratio is 6.9-7.1, and the total deformation is ≤85%.

[0030] Smelting: The metallurgical process of pure steel, ultra-low P, and extremely low S is adopted to ensure the uniformity of the structure of the continuous casting slab. The design range of the main chemical composition of the steel is shown in Table 1:

[0031] C

[0032] Steel is refined after smelting. The slab continuous casting strictly controls the defects of the slab, such as porosity and segregation, which should be controlled below B 0.5 level. The continuous casting slab adopts the cooling method of pile cooling to reduce the hydrogen content in the continuous casting slab and minim...

Embodiment 2

[0042] This embodiment is a specific production process of pipeline steel X70 with a compression ratio of about 8.5. The selected process is suitable for the production of X70 pipeline steel by the steckel mill. The thickness of the billet is about 150mm, the thickness of the finished plate is about 17-17.5mm, the range of compression ratio is 8.2-8.6, and the total deformation is ≤89%.

[0043] Smelting: The metallurgical process of pure steel, ultra-low P, and extremely low S is adopted to ensure the uniformity of the continuous casting slab. The main chemical composition design range is shown in Table 3:

[0044] C

Si

mn

P

S

Nb

Ti

Mo

0.03~0.0

6

0.15-0.3

1.55~1.6

5

<0.01

<0.002

0.03~0.05

0.015~0.02

5

0.15-0.2

5

[0045] Steel is refined after smelting. The slab continuous casting strictly controls the defects of the slab, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com