Radiator

A technology of radiators and radiator fins, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., which can solve the problems of low water leakage probability, high manufacturing cost, and complicated manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

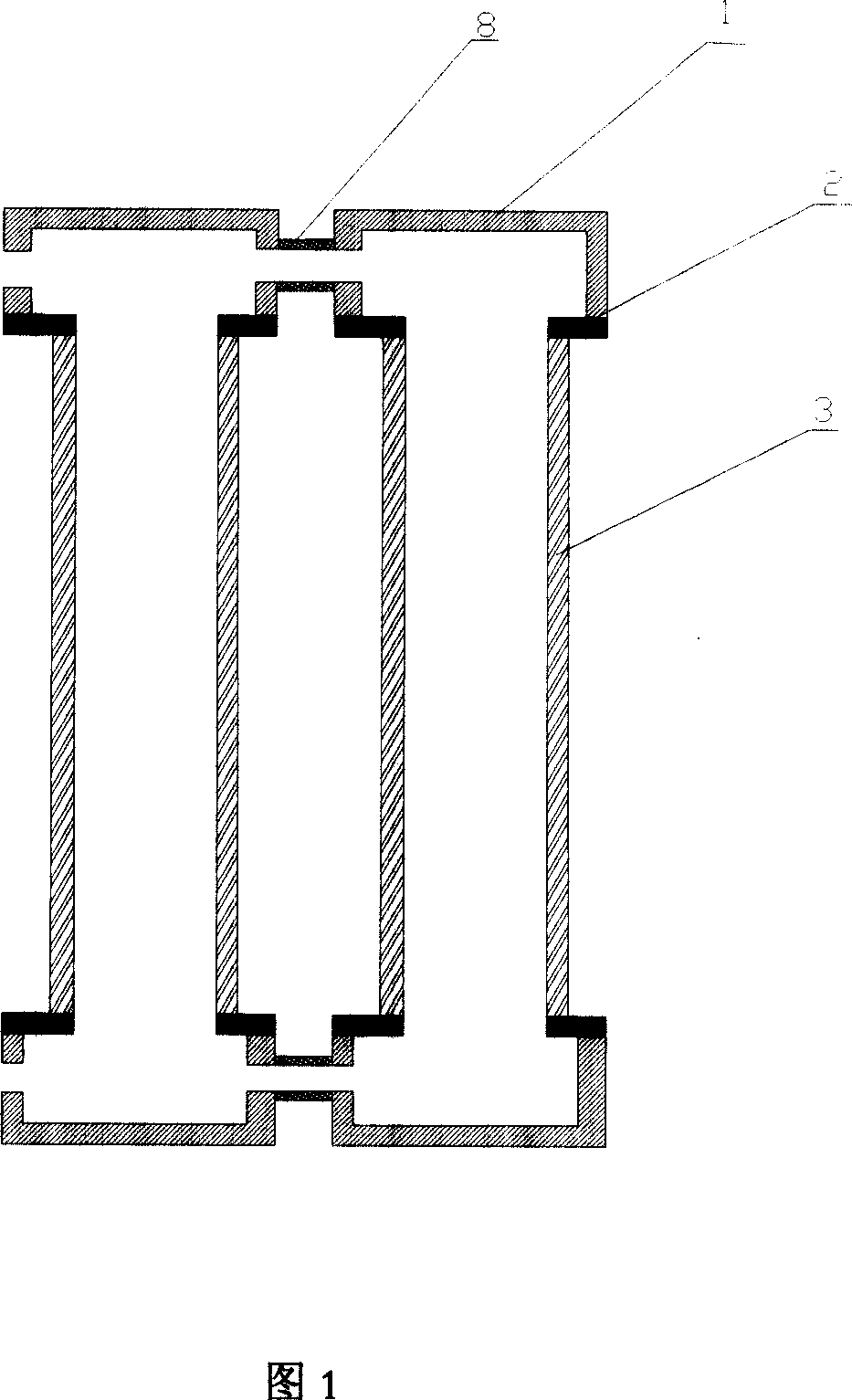

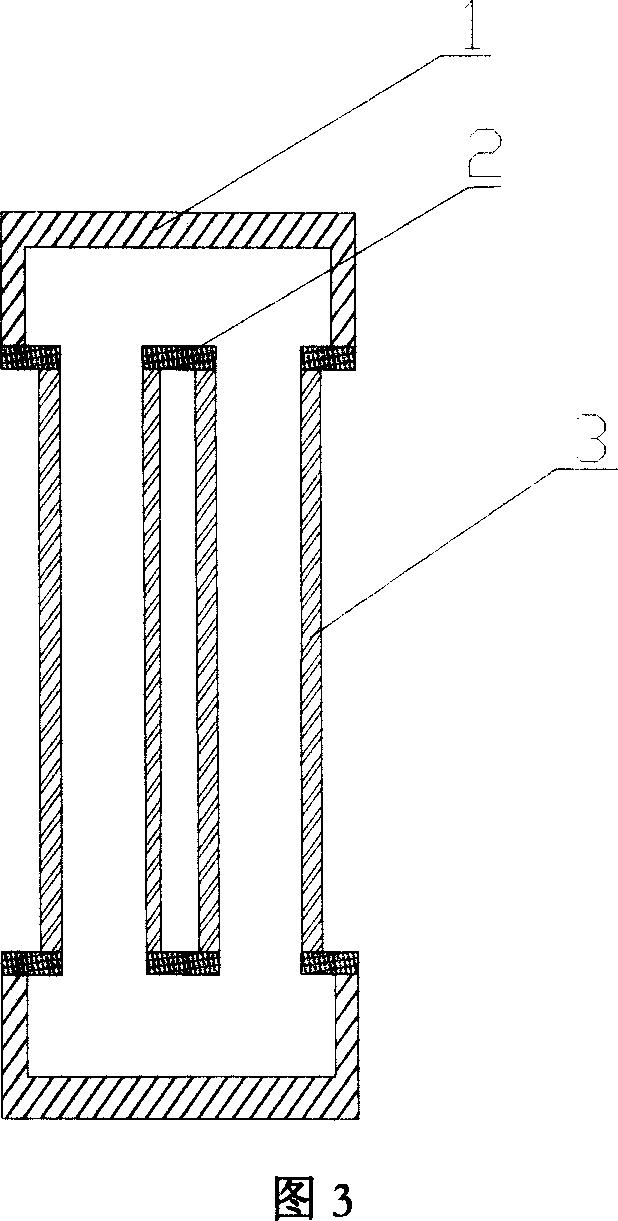

[0029] Below in conjunction with accompanying drawing this radiator of this invention will be further described, but not as the limitation of this invention:

[0030] A kind of radiator, as shown in Figure 1, is made up of more than one sheet radiator shown in Figure 2, as shown in Figure 1, Figure 2, described radiator sheet comprises two ends column head, middle cooling pipe 2 , as shown in Figure 1, Figure 2, Figure 3, and Figure 4, the column head includes a column cap 1 and a column cover 2. The column cap 1 is a cavity formed by stamping with one end open and one end closed. The column Cap 1 opening is welded with column cover 2, and described column cover 2 shape as shown in Figure 4, Figure 5, Figure 6, Figure 7 is consistent with column cap 1 opening, and column cover 2 is provided with port 4, and column cap 1 It is welded together with the column cover 2 to form a column head, and the column head is provided with a heat dissipation pipe connection port, and the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com