Tube type heat exchanger

A tubular heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problems of low heat exchange power density, insufficient compact structure, and increased heat exchange area, etc. To achieve the effect of good noise reduction, compact structure and increased heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Traditional tubular heat exchangers are generally composed of heat exchange tubes, enhanced heat exchange elements and auxiliary heat exchange devices. Enhanced heat exchange elements can be arranged inside and / or outside the heat exchange tubes, such as aluminum foil, fins, etc. , the role of the turbulence core arranged in the heat exchange tube is to enhance the heat exchange, and the auxiliary heat exchange device is used to accelerate the flow of the fluid medium, and the function is also to enhance the heat exchange effect, such as the commonly used auxiliary heat exchange devices such as fans and water pumps .

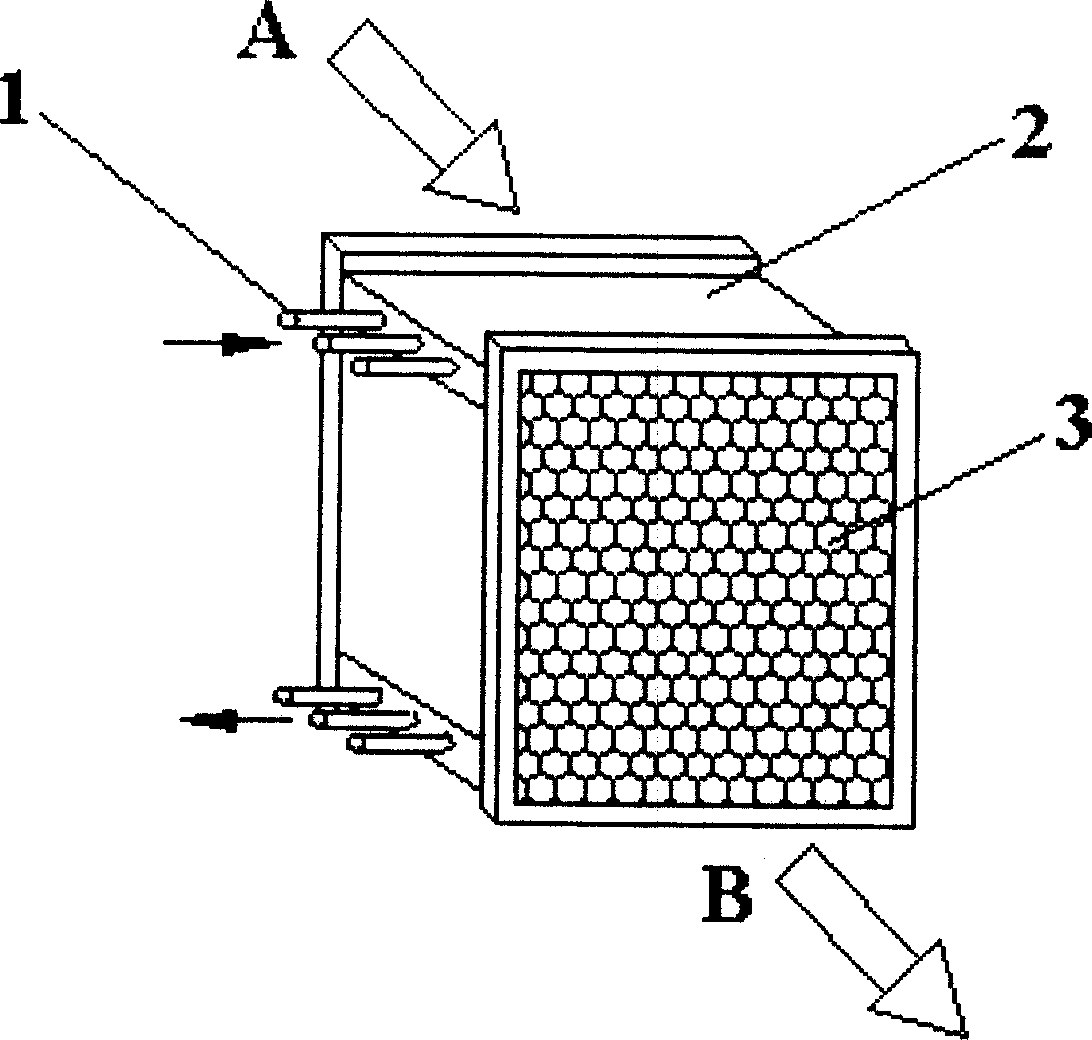

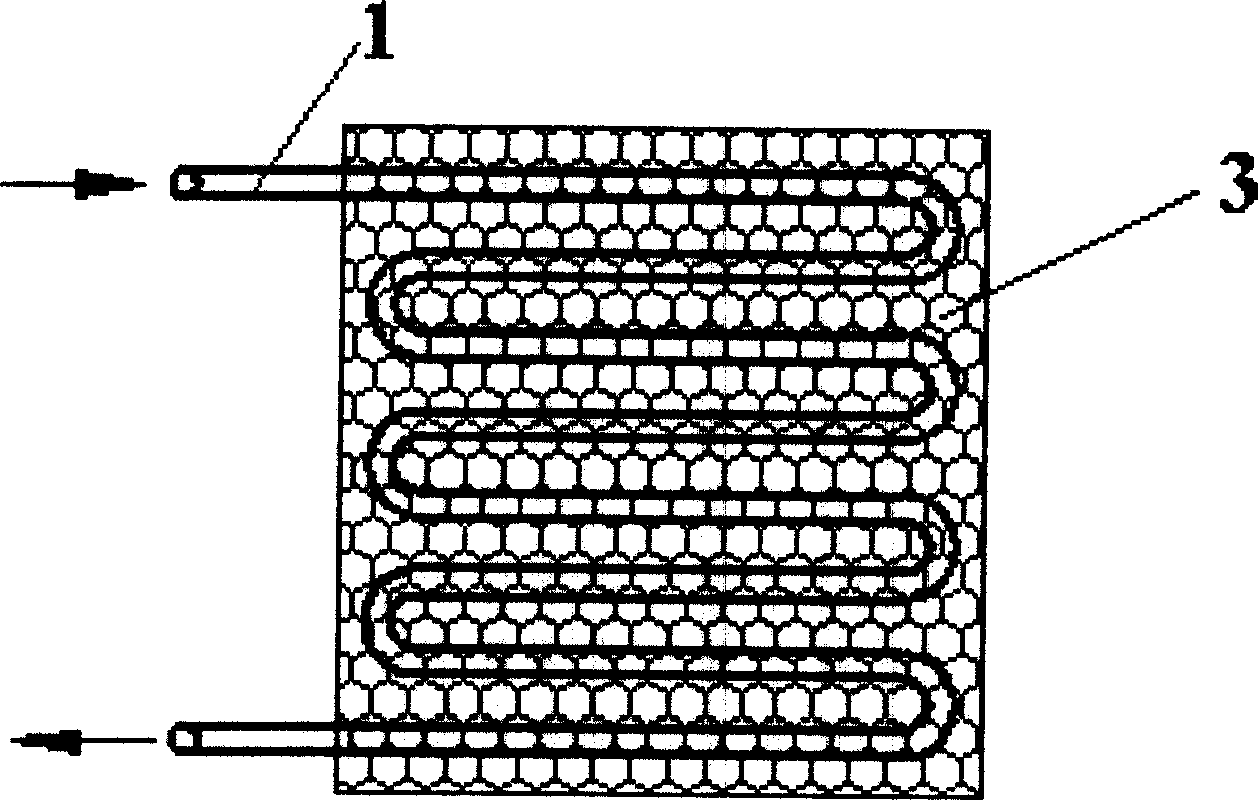

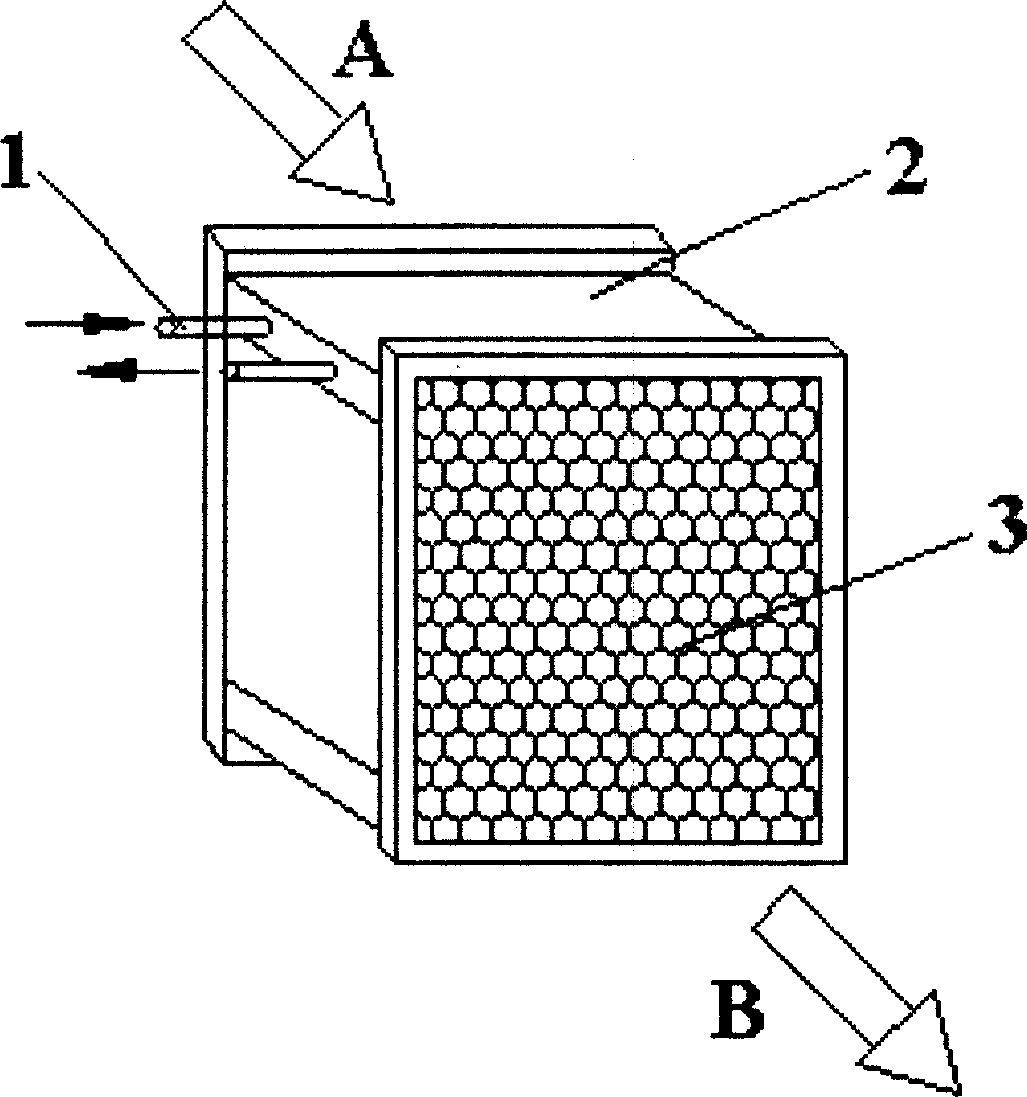

[0022] figure 1 One embodiment of the invention is shown. The heat exchanger consists of a heat exchange tube 1 and a metal foam 3 covering the surface of the heat exchange tube 1. The metal foam 3 is burnt on the outer surface of the heat exchange tube 1. Of course, the metal foam 3 can also be bonded. , welding and other methods to connect with the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com