Transparent ceramic material of dual adulterated yttruim aluminum garnet, and prepartion method

A technology of yttrium aluminum garnet and transparent ceramics, which is applied in the field of laser transparent ceramic materials preparation, can solve the problems of low thermal conductivity, low thermal expansion coefficient, and unsatisfactory laser efficiency, and achieve high linear transmittance and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

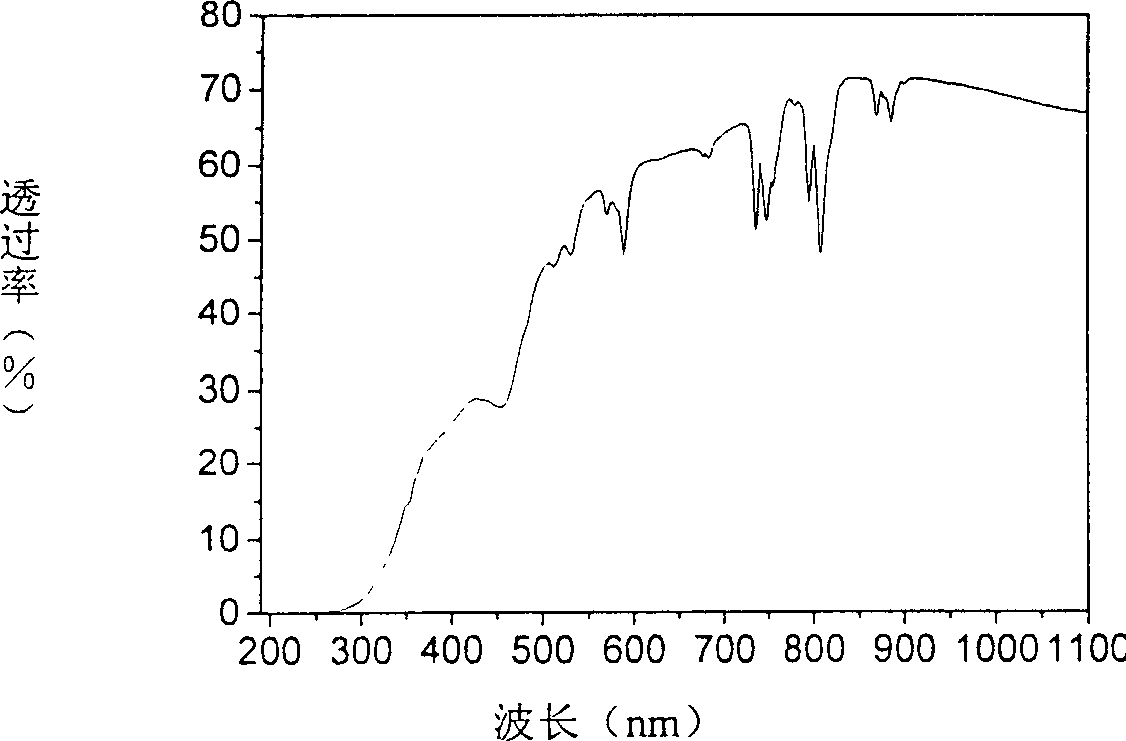

Image

Examples

Embodiment 1

[0046] 25.4645g of α-Al with a purity of 99.99% 2 o 3 Powder, 33.4778g of Y with a purity of 99.99% 2 o 3 Powder, 0.5047g Nd with a purity of 99.95% 2 o 3 Powder, 0.0280g of CaO powder with a purity of 99.99%, 0.0380g of Cr with a purity of 99.99% 2 o 3 Put the powder and 0.2976g of high-purity TEOS into a polytetrafluoroethylene ball mill jar, add 180g of high-purity agate balls and 22ml of absolute ethanol, and then ball mill for 10 hours. After drying in an oven at 90°C, it was ground through a 100-mesh sieve. Use 100MPa pressure to press axially and unidirectionally, press it into a Φ20 disc, and then cold isostatic press under 300MPa pressure to further increase the density of the green body. Sintering is carried out in a vacuum sintering furnace, and the sample is placed in a molybdenum crucible. The heating rate of the furnace is: 30°C / min from room temperature to 1150°C, 10°C / min from 1150°C to 1780°C, and 10 hours at 1780°C. From 1780°C to 1500°C, the tempera...

Embodiment 2

[0049] 25.4645g of α-Al with a purity of 99.99% 2 o 3 Powder, 33.4778g of Y with a purity of 99.99% 2 o 3 Powder, 0.5047g Nd with a purity of 99.95% 2 o 3 Powder, 0.0280g of CaO powder with a purity of 99.99%, 0.0380g of Cr with a purity of 99.99% 2 o 3 Put the powder and 0.2976g of high-purity TEOS into a polytetrafluoroethylene ball mill jar, add 180g of high-purity agate balls and 22ml of absolute ethanol, and then ball mill for 10 hours. After drying in an oven at 90°C, it was ground through a 100-mesh sieve. Use 100MPa pressure to press axially and unidirectionally, press it into a Φ20 disc, and then cold isostatic press under 300MPa pressure to further increase the density of the green body. Sintering is carried out in a vacuum sintering furnace, and the sample is placed in a molybdenum crucible. The heating mechanism of the furnace is: 30°C / min from room temperature to 1200°C, 10°C / min from 1200°C to 1770°C, and 30 hours at 1770°C. From 1770°C to 1500°C, the te...

Embodiment 3

[0051] 25.4645g of α-Al with a purity of 99.99% 2 o 3 Powder, 33.4778g of Y with a purity of 99.99% 2 o 3 Powder, 0.5047g Nd with a purity of 99.95% 2 o 3 Powder, 0.0280g of CaO powder with a purity of 99.99%, 0.0380g of Cr with a purity of 99.99% 2 o 3 Put the powder and 0.2976g of high-purity TEOS into a polytetrafluoroethylene ball mill jar, add 180g of high-purity agate balls and 22ml of absolute ethanol, and then ball mill for 10 hours. After drying in an oven at 90°C, it was ground through a 100-mesh sieve. Use 100MPa pressure to press axially and unidirectionally, press it into a Φ20 disc, and then cold isostatic press under 300MPa pressure to further increase the density of the green body. The biscuit is pre-sintered in a silicon carbide rod furnace at 800°C, and the heating rate is 5°C / min. Then the pre-sintered body continues to be sintered in a vacuum sintering furnace, and the sample is placed in a molybdenum crucible. The heating rate of the furnace is: 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com