Anode material for non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery using such anode material

A non-aqueous electrolyte and negative electrode material technology, applied in the field of non-aqueous electrolyte batteries, can solve the problems of low industrial reliability, difficult carbon fiber rolling/cutting operations, and difficulty in determining material parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0169] (a) Preparation of negative electrode materials

[0170] The coal-based pitch was heated at 425° C. for 5 hours in an inert gas atmosphere to obtain a coal-based mesophase pitch with a softening temperature of 220° C. The mesophase ratio at this time was 92%.

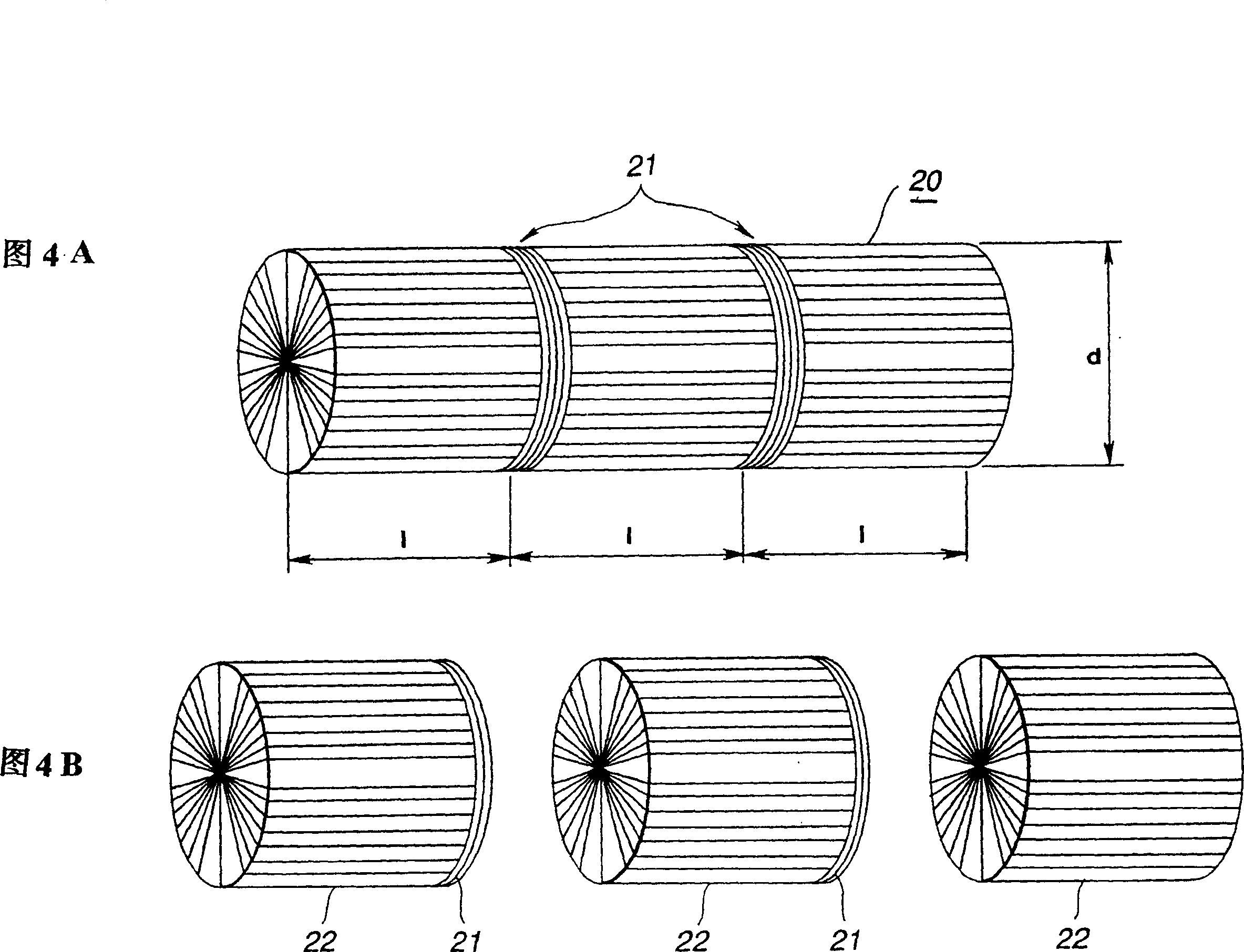

[0171] The coal-based mesophase pitch thus obtained was subjected to a discharge fiber-forming operation at a temperature of 300° C. at a predetermined demolding pressure, thereby obtaining precursor fibers. Then, infusible treatment is performed at a temperature of 260° C., and then calcined in an inert gas atmosphere at a temperature of 1000° C. to obtain carbon fibers. This carbon fiber is further heat-treated at a temperature of 3000° C. in an inert gas atmosphere, and finally subjected to jet crushing to obtain graphitized carbon fiber powder.

[0172] The cross-sectional shape of the powder thus obtained was observed with an electron microscope to determine its shape and size. In addition, the area filli...

Embodiment 2

[0189] The preparation of graphitized carbon fibers was similar to Example 1, with the only difference that the precursor fibers used were prepared by heating coal-based pitch at 425 °C for 2 hours in an inert gas atmosphere, and then Heated at 400°C for 2 hours, and then heated at 350°C for 24 hours in an inert gas atmosphere. Finally, the heat-treated coal-based mesophase pitch (95% of the mesophase ratio) was discharged into fibers, and the non-aqueous Electrolyte battery.

[0190] In this example, the fiber shape and average size of the graphitized carbon fibers obtained by the above-mentioned method were measured in a similar manner to Example 1, thereby calculating the area filling rate and circularity ratio, and finally measuring the bulk density.

[0191] The results are shown in Table 1. In addition, the cross-sectional shape of the fiber is shown in Figure 8 middle.

Embodiment 3

[0193] The preparation of graphitized carbon fibers is similar to that of Example 1, with only the following difference, that is, the precursor fibers used are prepared in this way: oil-based pitch was heated at 430 ° C for 3 hours in an inert gas atmosphere, and then heat-treated The oil-based mesophase pitch with a softening temperature of 210°C is discharged into fibers, and a non-aqueous electrolyte battery is further prepared.

[0194] In this example, the fiber shape and average size of the graphitized carbon fibers obtained by the above-mentioned method were measured in a similar manner to Example 1, so as to calculate the area filling ratio and roundness ratio, and finally measure the bulk density.

[0195] The results are shown in Table 1. In addition, the cross-sectional shape of the fiber is shown in Figure 9 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com