Fuel supply pump and tappet structure body

A fuel supply pump and structure technology, applied in fuel injection pumps, fuel injection devices, pumps, etc., can solve the problems of reduced durability and easy damage to the pump casing, and achieve the effects of improved durability, simple structure, and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

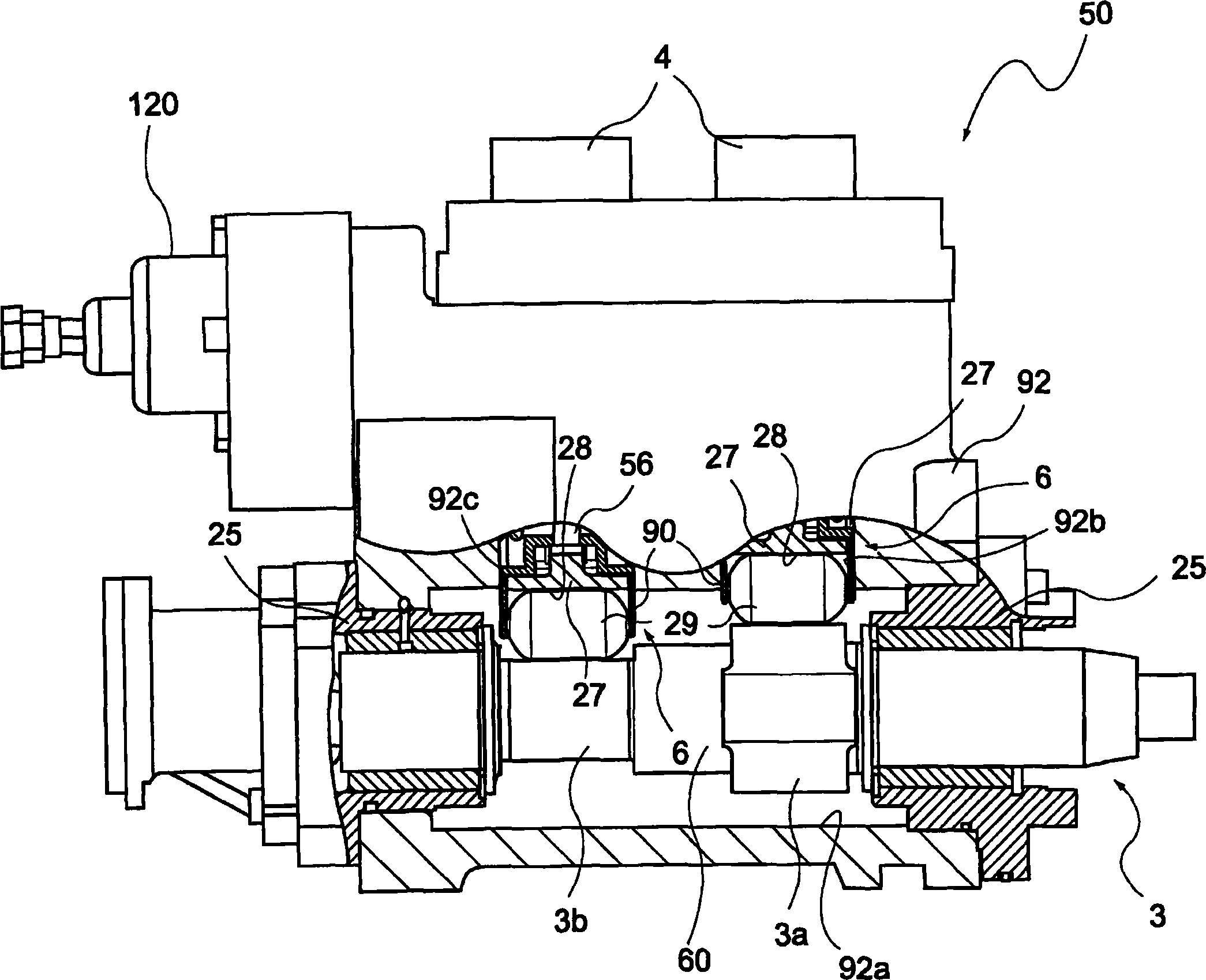

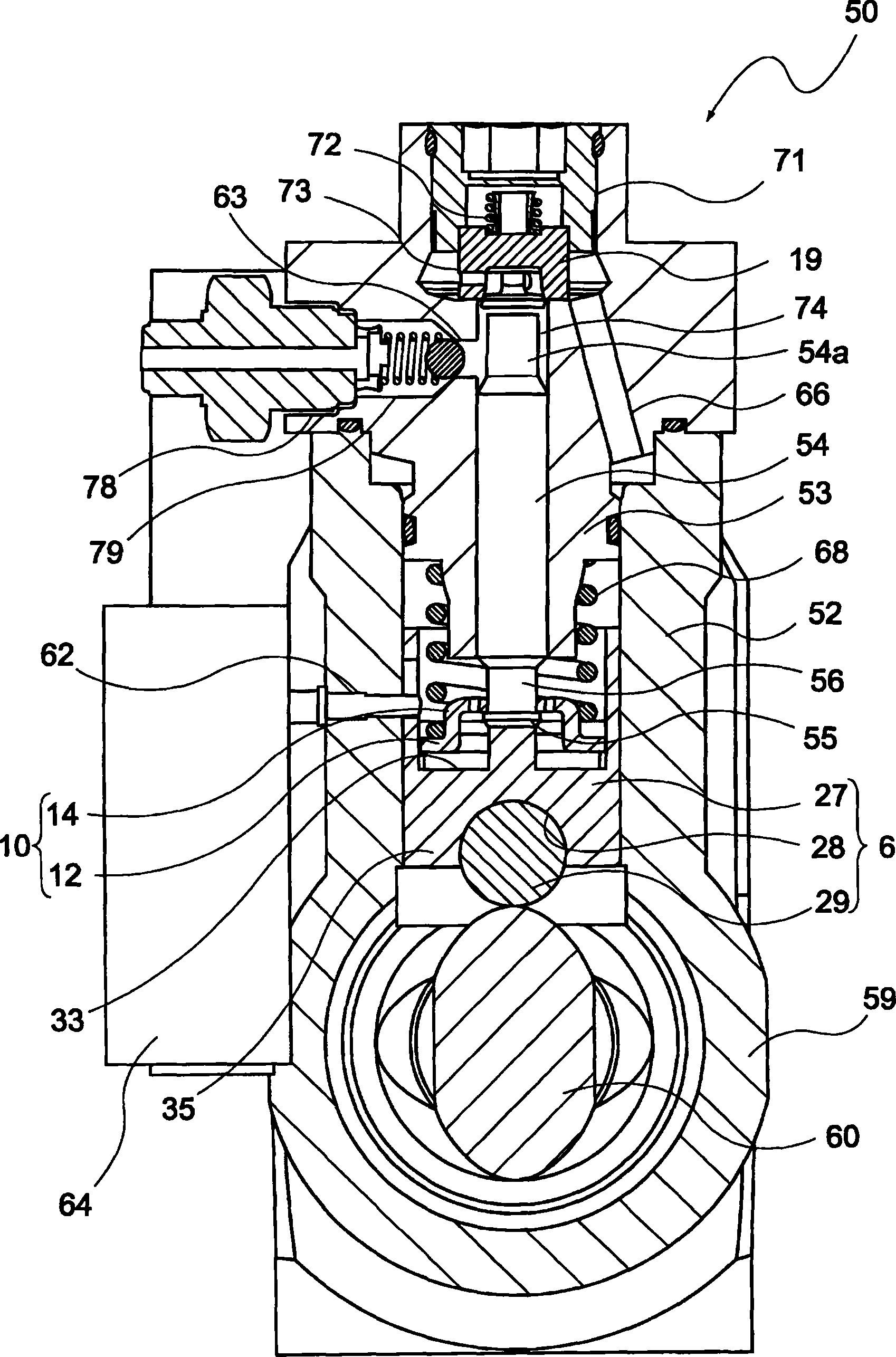

[0060] Such as figure 1 As shown, the first embodiment is a fuel supply pump 50 having a lifter structure 6 including a roller 29 and a lifter body portion 27 for accommodating the roller 29, the fuel supply pump It is characterized in that it has a plate-shaped or wire-shaped restricting unit 90 for rotatably holding the roller 29 in the roller seat 28 of the tappet body 27 and restricting the movement of the roller 29 in the direction of the rotation axis.

[0061] Hereinafter, the aforementioned fuel supply pump 50 will be specifically described in terms of constituent elements and the like.

[0062] 1. Basic method of fuel supply pump

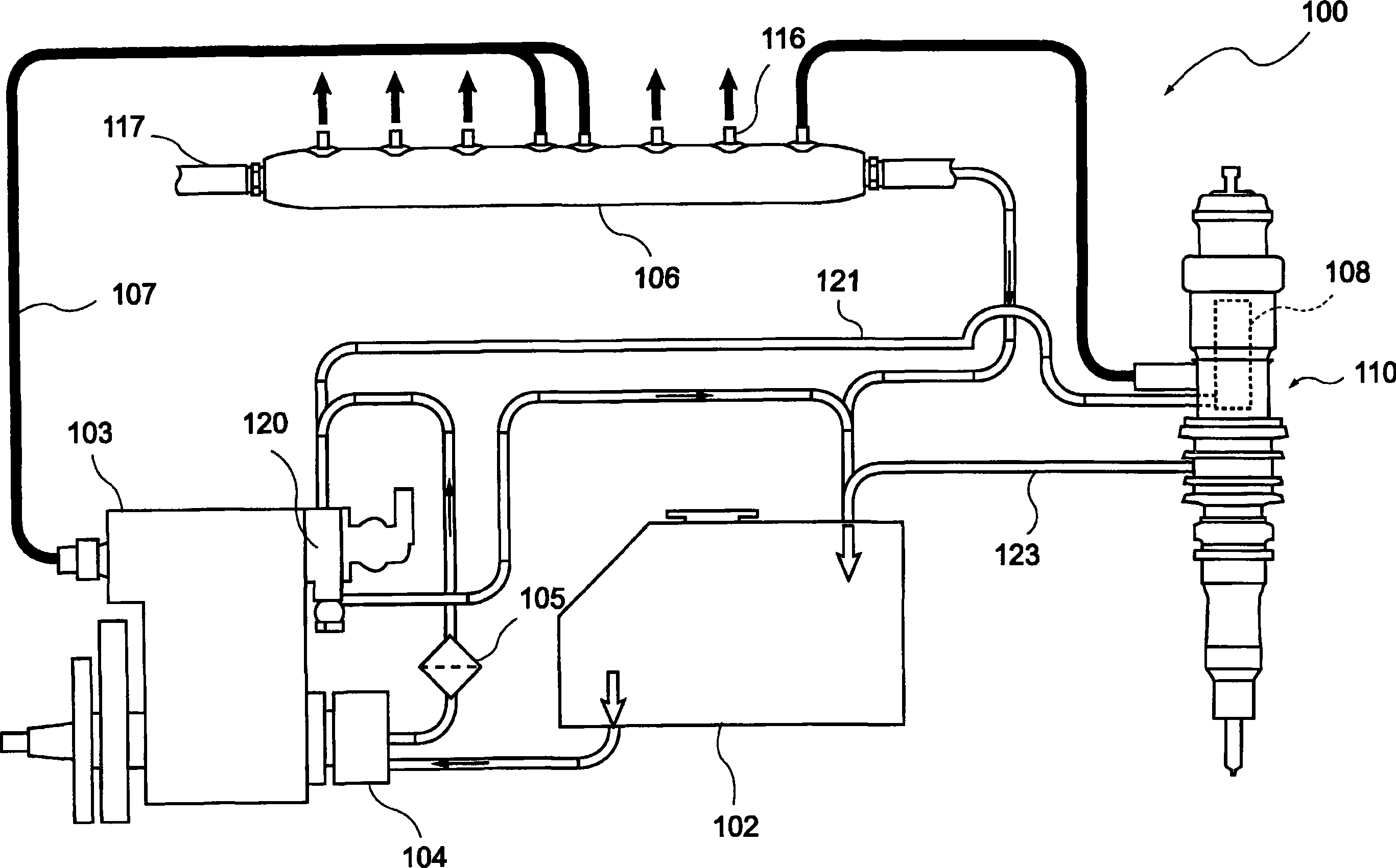

[0063] Although there is no particular limitation on the basic form of the fuel supply pump, it is preferable that, for example, figure 1 and figure 2 The fuel supply pump 50 is shown. That is, the fuel supply pump 50 is preferably composed of, for example, a pump housing 52 , a plunger barrel (pump barrel) 53 , a plunger 54 , a leaf...

no. 2 approach

[0117] Such as Figure 7 (a)~(b), Figure 8 (a)~(b) and Figure 9 As shown in (a) to (b), the second embodiment is a lifter structure 6, the lifter structure includes a roller 29 and a lifter body part 27 for accommodating the roller 29, the lifter structure It is characterized in that it has a plate-shaped or wire-shaped restricting unit 90 for rotating and holding the roller 29 on the roller seat 28 of the tappet body part 27, and restricting the movement of the roller 29 in the direction of the rotation axis.

[0118] Hereinafter, the basic structure of the lifter structure 6 , the divided lifter body portion 27 and the roller 29 , and the restricting unit 90 will be specifically described with reference to the corresponding drawings.

[0119] 1. Basic structure

[0120] Such as Figure 7 (a)~(b), Figure 8 (a)~(b) and Figure 9 As shown in (a) to (b), preferably, the tappet structure 6 is basically composed of the following components: a spring piece 10; a base body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com