Method of manufacturing liquid crystal display device

A technology of a liquid crystal display device and a manufacturing method, which are applied in the photoengraving process of the pattern surface, the exposure device of the photoengraving process, optics, etc., can solve the problems such as the inability to properly correct the positional deviation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

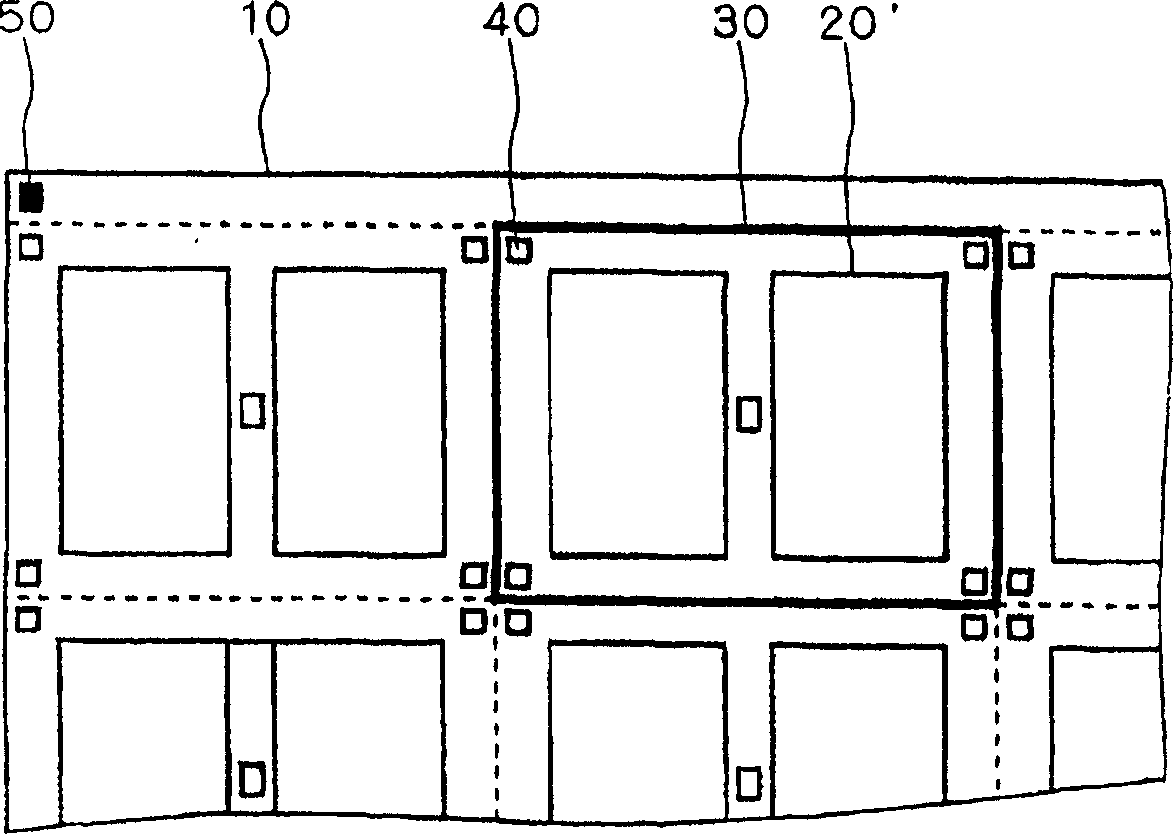

[0029] figure 1 It is a plan view showing an example of an array substrate used in the liquid crystal display device of Example 1.

[0030] Such as figure 1 As shown, on the array substrate 10, a plurality of display regions 20 corresponding to one display substrate mounted on one liquid crystal display device are formed in parallel by stepper exposure. On the display area 20 are formed pixel electrodes, thin film transistors, source wiring, gate wiring, etc. ( figure 1 not shown). The array substrate 10 is divided into array shot regions 30 (thick line portions) serving as irradiation units in the divided exposure. figure 1 One display area 20 is divided into four array irradiation areas 30 . That is, one array irradiation area 30 includes 1 / 4 display area 20 .

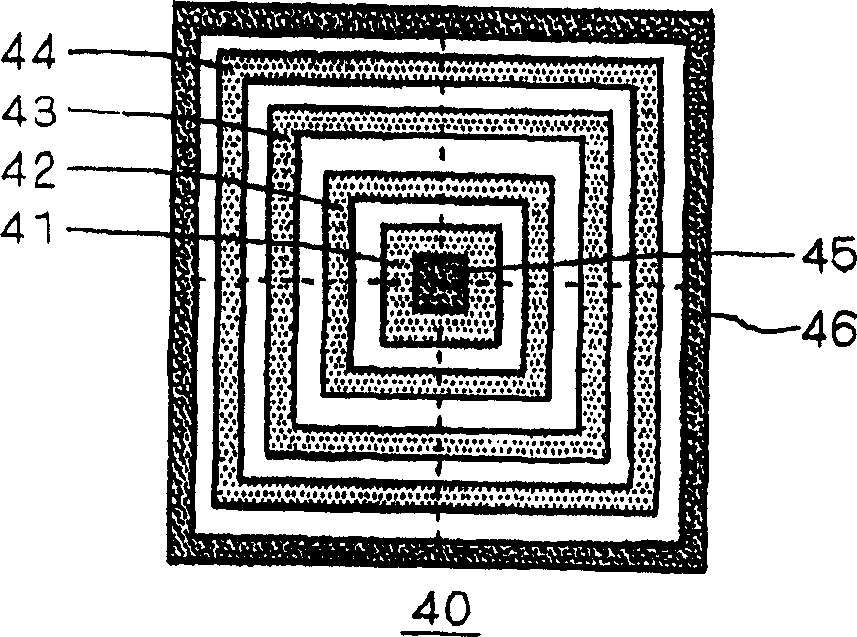

[0031] At least one positioning mark 40 is provided in one array irradiation area 30 ( figure 1 3 of them). In addition, the array substrate 10 has a rectangular shape, and superimposing marks 50 serving as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com