Powder catalyst for synthesizing high strength and excellent quality diamond with low prodn. cost

A low-cost, diamond technology, applied in the application of ultra-high pressure process, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of low diamond output rate and inability to synthesize diamond, etc. problem, to achieve the effect of strengthening interaction, reducing oxygen content, and reducing raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A powder catalyst for synthesizing coarse-grained, high-strength diamonds in this embodiment has an alloy ingredient composition of Ni: 30%, Mn: 0.2%, C: 0.2%, and the balance is Fe.

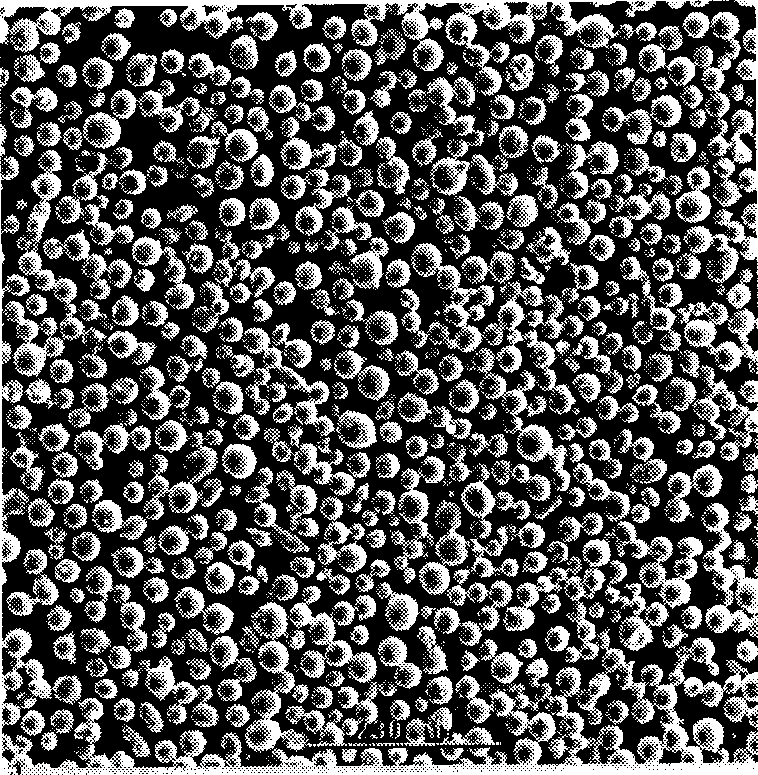

[0025] Weigh the ingredients of Ni, Fe, and Mn with a purity of 99.9%, melt the ingredients in an intermediate frequency induction furnace under the protection of inert gas, and prepare a powder catalyst for synthetic diamond by vacuum / inert gas atomization technology. The obtained new powder catalyst was analyzed, and the composition of the alloy powder was Ni: 29.8%, Mn: 0.16%, C: 0.18%, N: 150PPm, O: 120PPm, and the balance was Fe.

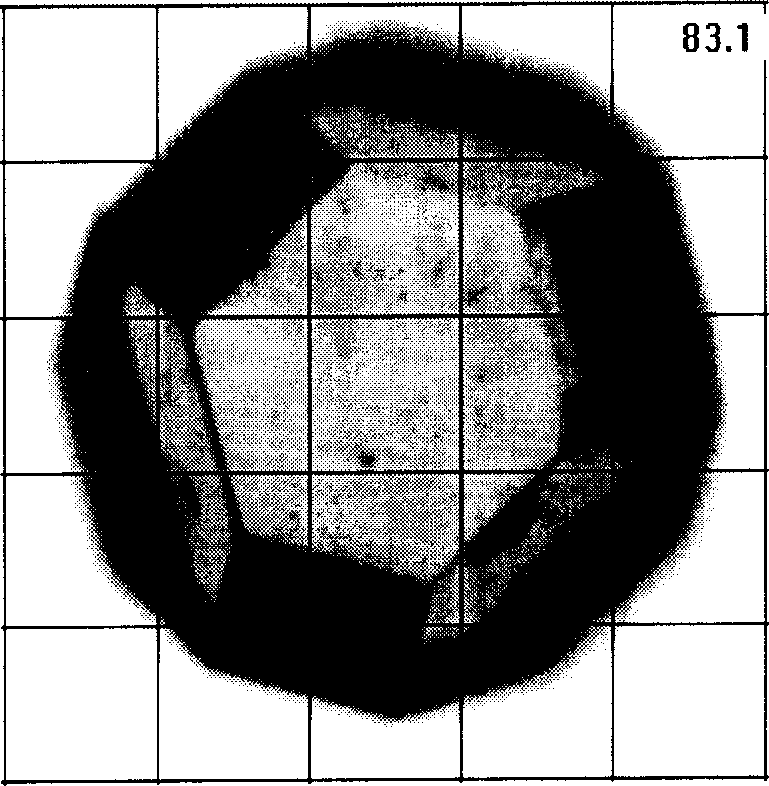

[0026] The alloy is sieved, and the alloy powder with a particle size range of -200 mesh is uniformly mixed with graphite powder in a certain proportion, and the diamond is synthesized under a certain pressure and temperature. The proportion of particle size ≥ 60 mesh accounts for more than 70%, of which 40 / 45 mesh diamond The performance is shown in Table...

Embodiment 2

[0028] Its equipment and operation method are basically the same as in Example 1, the only difference is that, by weight percentage, the ingredients of the alloy are: Ni: 30%, Mn: 0.3%, C: 0.2%, Cr: 0.02%, and the balance For Fe.

[0029] The obtained new powder catalyst was analyzed, and the composition of the alloy powder was Ni: 29.92%, Mn: 0.28%, C: 0.18%, Cr: 0.018%, N: 160PPm, O: 150PPm, and the balance was Fe.

[0030] The alloy powder with a size of -200 mesh and graphite powder are mixed evenly in a certain proportion, and diamonds are synthesized under a certain pressure and temperature. The proportion of particle size ≥ 60 mesh accounts for more than 70%. The properties of 40 / 45 mesh diamonds are shown in Table 1.

Embodiment 3

[0032] Its equipment and operation method are basically the same as in Example 1, the only difference is that, by weight percentage, the ingredients of the alloy are: Ni: 25%, Mn: 0.2%, C: 0.4%, and the balance is Fe.

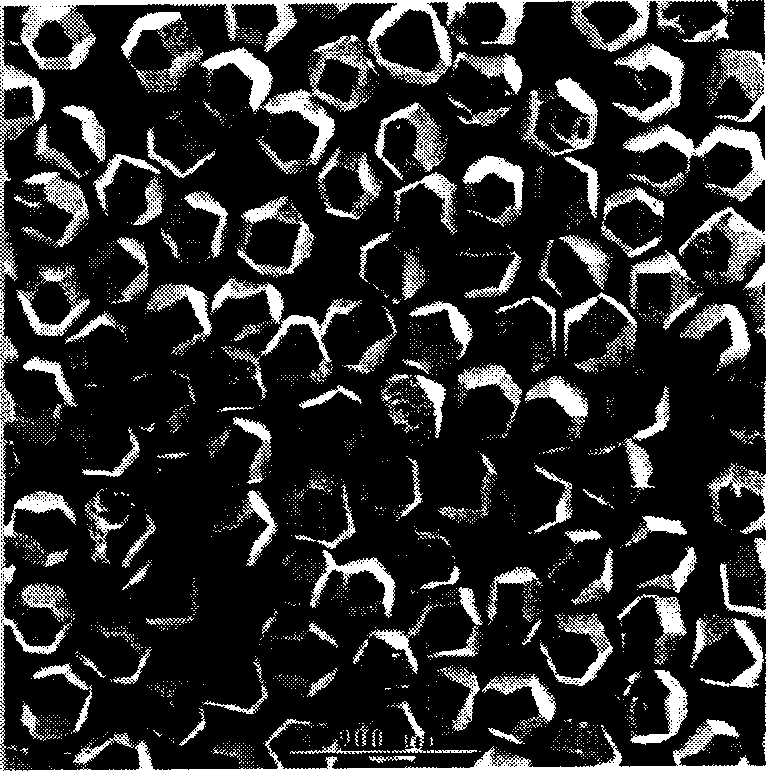

[0033] After the ingredients are melted, the prefabricated alloy ingots are poured immediately, and then the prefabricated alloy ingots are melted, and a new type of powder catalyst for synthesizing coarse particles and high-strength diamonds is prepared by vacuum / inert gas atomization technology.

[0034] The obtained new powder catalyst was analyzed, and the composition of the alloy powder was Ni: 24.75%, Mn: 0.16%, C: 0.38%, N: 120PPm, O: 120PPm, and the balance was Fe.

[0035] The alloy powder with a particle size range of -150 mesh and graphite powder are mixed evenly in a certain proportion, and diamonds are synthesized under a certain pressure and temperature. The proportion of particle size ≥ 60 mesh accounts for more than 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com