Online detecting method and device for hot rolling strip surface fault based on laser line light source

A technology of laser line light source and hot-rolled strip steel, which is applied in the direction of optical testing for defects/defects, etc., to achieve good image quality, good light concentration and monochromaticity, and reduce hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

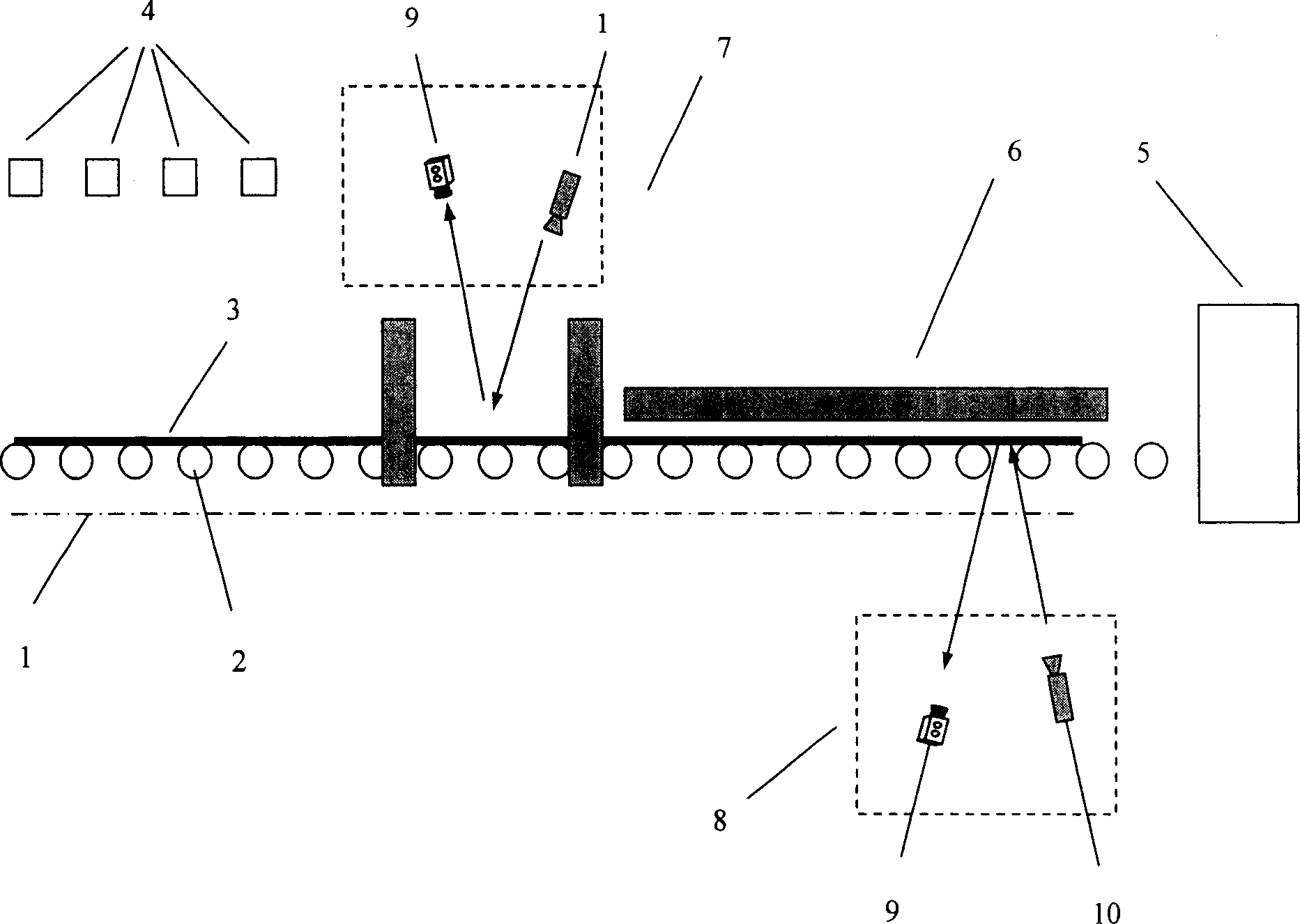

[0015] exist figure 1 Among them, behind the laminar flow cooling (4) and above the roller table in front of the side guide plate (6), an upper surface detection chamber (7) is built, and an upper surface detection device is installed in the upper surface detection chamber (7), including a linear array CCD camera (9) and laser line light source (10). The installation position of the upper surface detection device should be away from the laminar flow cooling, but it should not affect the maintenance and replacement of the side guide plate. Under the roller table in front of the coiler (5) build the lower surface detection cabin (8), install the lower surface detection device in the lower surface detection cabin (8), including a linear array CCD camera (9) and a laser line light source ( 10), because the lower surface detection device will not affect the replacement of the side guide plate, so its installation position should be as close as possible to the coiler to reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com