Solar panel component and processing technology

A technology for solar panels and solar cells, applied in the field of solar cells, can solve the problems of lowering conversion rate, increasing defective rate of electrode printing, increasing the distance of fine grid lines, etc., so as to improve the connection speed and accuracy, reduce the The phenomenon of broken gate and the effect of increasing gate line thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

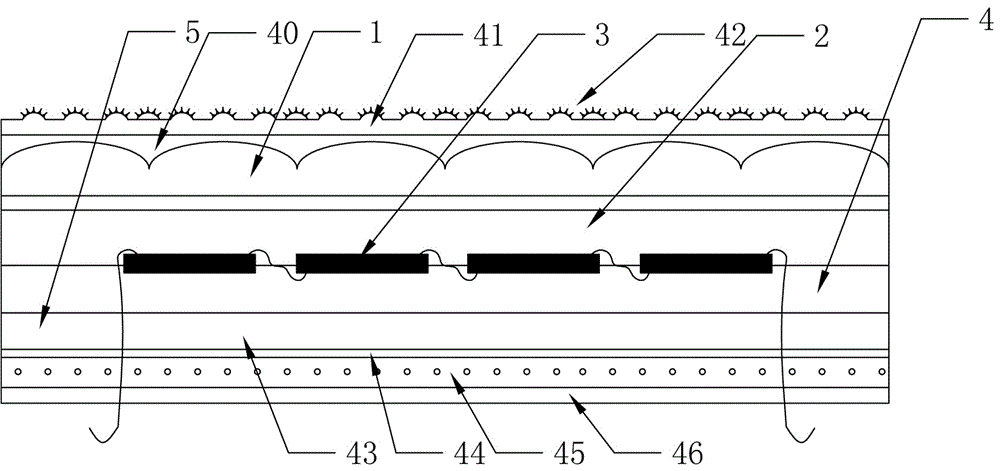

[0063] Such as figure 1 As shown, a solar cell panel assembly includes a tempered glass layer 1, a first EVA film layer 2, a solar battery sheet 3, a second EVA film layer 4, a coated aluminum alloy backplane layer 5 and a frame structure.

[0064] Such as figure 1 As shown, the upper surface of the tempered glass layer 1 is an arc-shaped surface composed of a plurality of arc-shaped protrusions, and a self-cleaning purification layer is provided on the arc-shaped surface. In this way, the dust layer on the surface of the solar panel is automatically treated to ensure the power generation efficiency.

[0065] Such as figure 1 As shown, the self-cleaning purification layer includes a polydimethylsiloxane layer 40 , a polymer adhesive 41 with protrusions evenly distributed at intervals on the upper end, and nanobeams 42 arranged on the protrusions of the polymer adhesive 41 . The polydimethylsiloxane layer 40 is a transparent film. The upper surface of the raised portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com