Positive electrode for lithium secondary battery, and lithium secondary battery using the same

A lithium secondary battery and positive electrode technology, which is applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte storage battery electrodes, etc., can solve the problem that the overheating of lithium secondary batteries cannot be greatly suppressed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

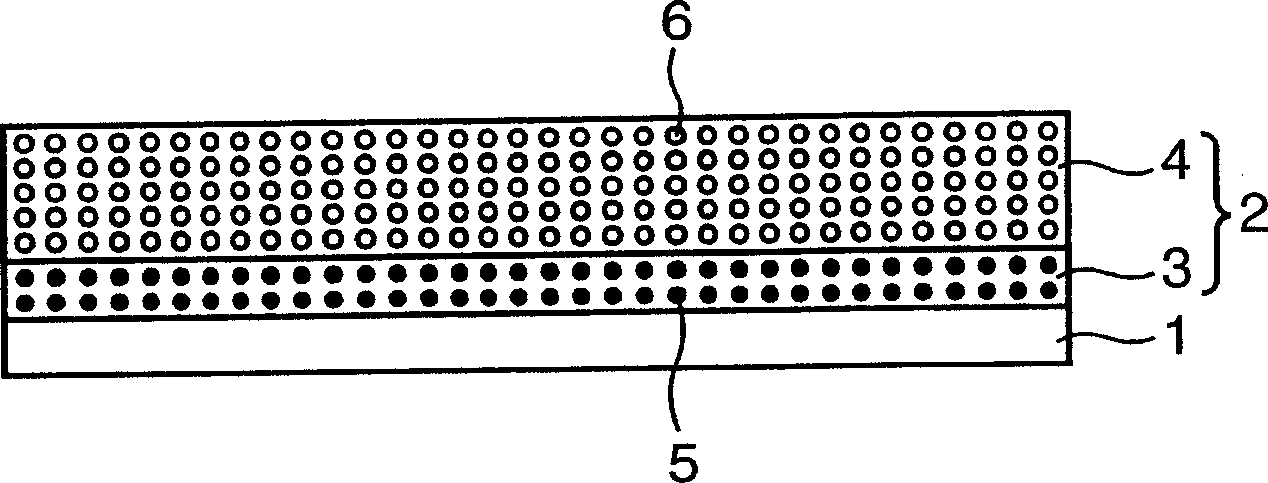

[0024] The positive electrode for a lithium secondary battery of the present embodiment is a positive electrode for a lithium secondary battery comprising a current collecting base material and a positive electrode coating film having a plurality of mixture layers on the current collecting base material; the positive electrode coating film contains Two or more lithium-containing compounds with different exothermic onset temperatures in the active material; among the two or more lithium-containing compounds, at least one lithium-containing compound has an exothermic onset temperature above 300°C; The first mixture layer closest to the electric base material contains at least one lithium-containing compound having an exothermic onset temperature of 300° C. or higher.

[0025] The positive electrode for a lithium secondary battery of this embodiment will be described with reference to the drawings.

[0026] figure 1 It is a schematic sectional view which shows an example of the ...

Embodiment approach 2

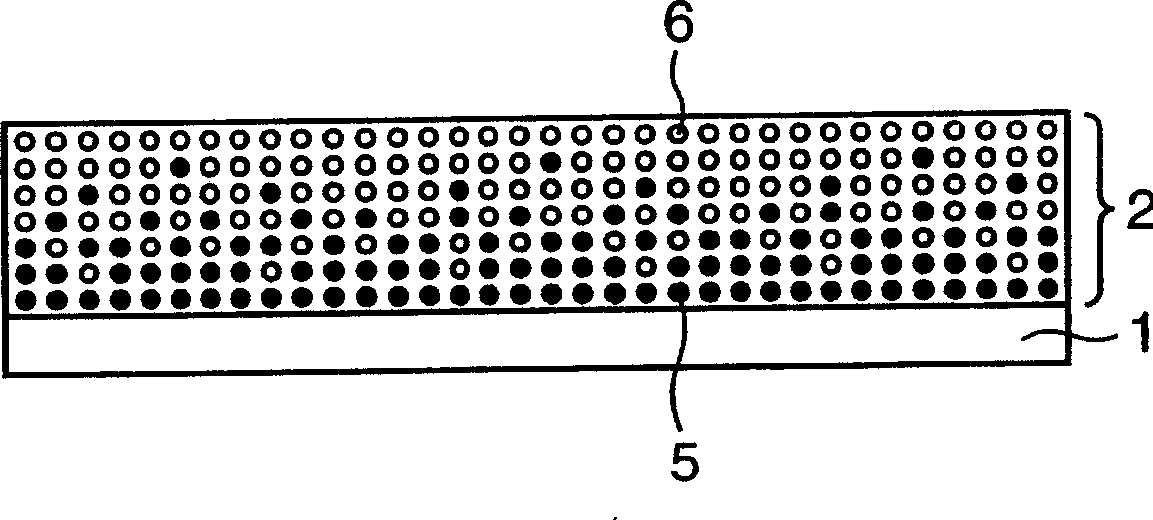

[0062] The positive electrode for a lithium secondary battery according to the present embodiment is a positive electrode in which two or more lithium-containing compounds having different heat generation onset temperatures are contained as positive electrode active materials in the positive electrode coating film formed on the current collecting substrate. ; At least one lithium-containing compound in the two or more lithium-containing compounds has a heat generation onset temperature above 300 ° C; in the thickness direction from the surface layer of the positive electrode coating to the current collector substrate, the heat generation onset temperature is at The content of the lithium-containing compound at 300° C. or higher increases from the surface layer side toward the current collector substrate side.

[0063] The positive electrode for a lithium secondary battery of this embodiment will be described with reference to the drawings. Since the current collecting base mat...

Embodiment

[0076] (i) Preparation of positive electrode active material

[0077] The positive electrode active materials a-1 to a-6 were prepared by the following methods, respectively.

[0078] (i-1)a-1

[0079] Will Li 2 CO 3 and CoCO 3 Mixing at a given molar ratio, calcining at 900°C for 10 hours, pulverizing and classifying, the chemical formula LiCoO 2 Represented positive electrode active material a-1.

[0080] (i-2)a-2

[0081] An aqueous solution containing cobalt sulfate with a concentration of 0.98 mol / liter and magnesium sulfate with a concentration of 0.02 mol / liter is continuously supplied to the reaction tank, and sodium hydroxide is added dropwise to the reaction tank so that the pH of the solution reaches 10 to 13. Synthesize precursors of active substances, wash thoroughly with water and allow to dry. As a result, the Co 0.98 Mg 0.02 (OH) 2 Expressed hydroxide. The precursor was mixed with lithium carbonate so that the molar ratio of lithium, cobalt, and magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com