Non-operating reversed and overspeed protector for automatic staircase or pavement

A technology for moving walks and escalators, applied in escalators, transportation and packaging, etc., can solve the problems of high operating noise and short service life, and achieve the effects of low operating cost, long service life, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the accompanying drawings.

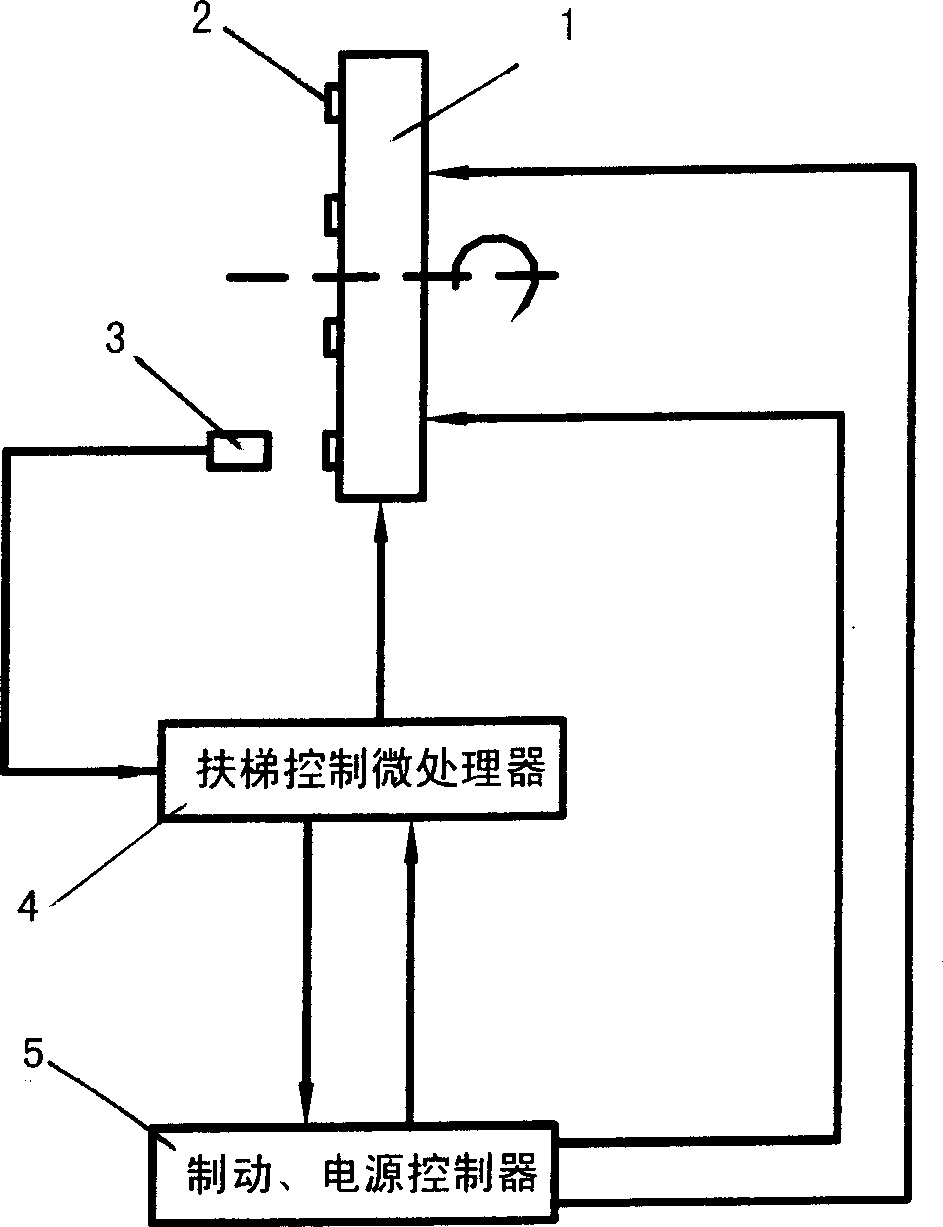

[0011] On one side of the rotating part 1 of the escalator or moving walkway, eight magnetic induction elements with the same polarity direction—small magnetic steel 2 are evenly embedded. The Hall proximity switch sensor element A1, A2 Hall proximity switch displacement sensor 3, the Hall proximity switch displacement sensor 3 is connected with the escalator control microprocessor 4, and the escalator control microprocessor 4 is connected with the braking and power control device 5 is connected. The above-mentioned main engine rotating part 1 may be a main engine flywheel or a main engine sprocket or a driving wheel.

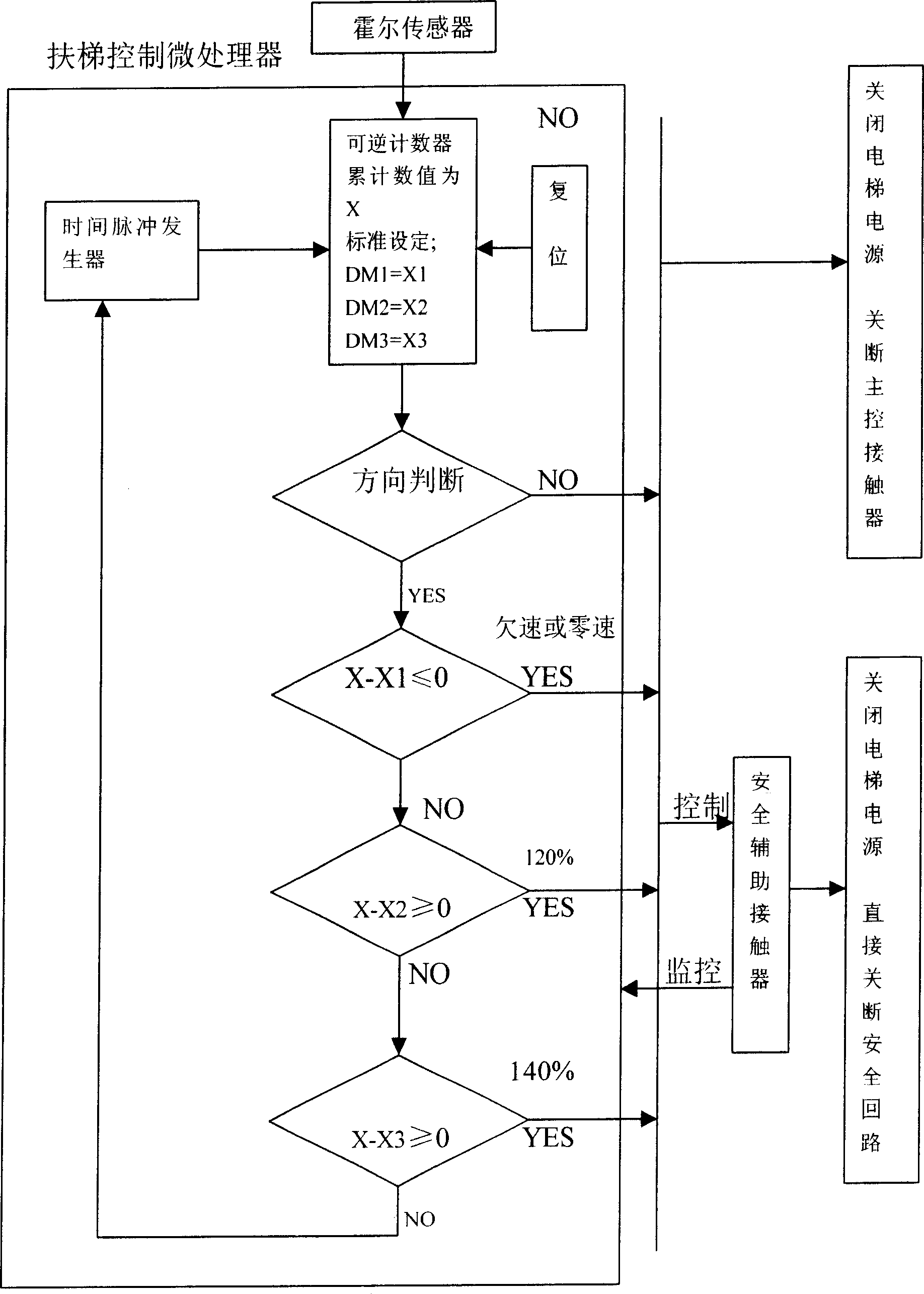

[0012] The working principle of the above device is: when the escalator or moving walk is working, the rotating part 1 of the main engine rotates at a certain speed, and whenever the magnetic steel 2 on the rotating part passes in front of the Hall proxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com