Diflunisal slow-releasing preparation and its making method

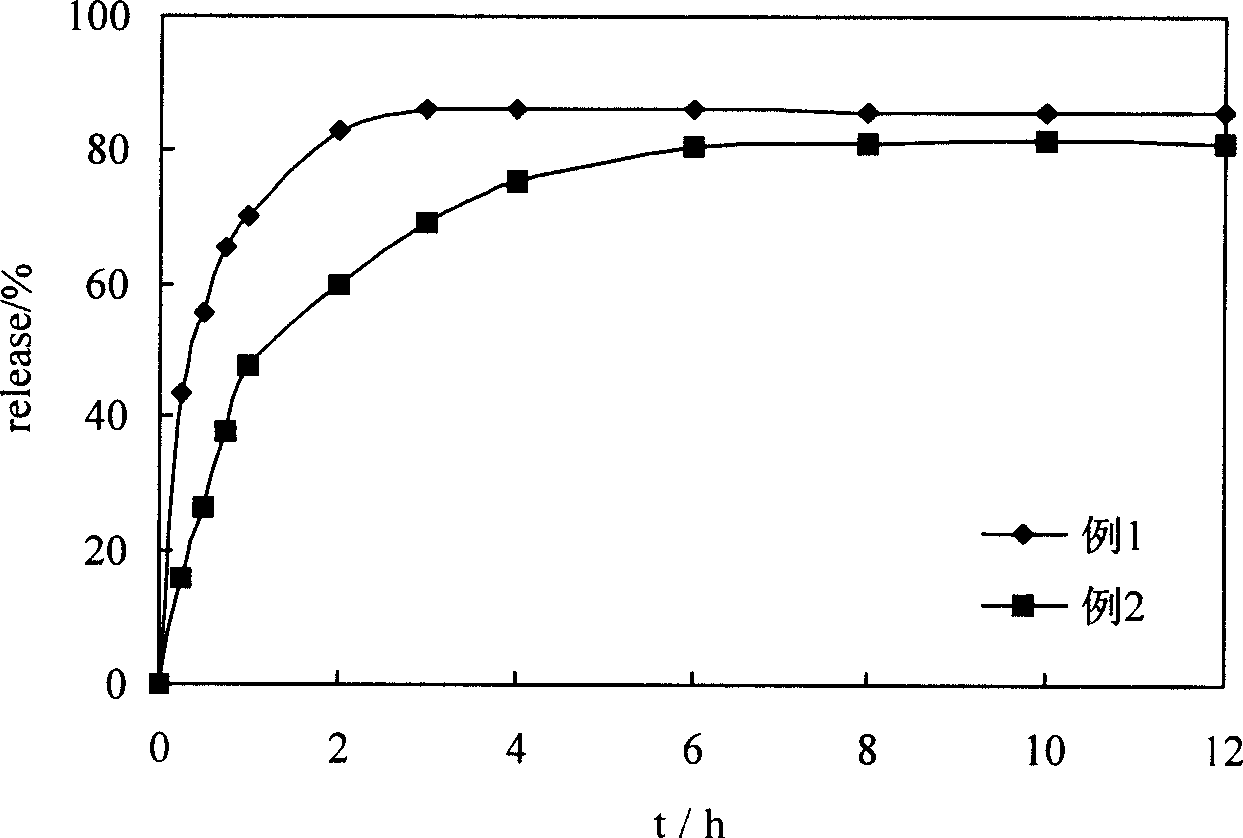

A technology of diflunisal and sustained-release preparations, which is applied in anti-inflammatory agents, pharmaceutical formulas, non-central analgesics, etc., can solve the problems that diflunisal slow-release preparations have not been reported, and achieve improved anti-inflammatory, The effect of reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 1.53g (6mmol) Mg (NO 3 ) 2 ·6H 2 O and 0.75g (2mmol) Al(NO 3 ) 3 9H 2 O was dissolved in 10mL deionized water, stirred to dissolve to obtain mixed liquid A; 1.79g (6mmol) of diflunisal (full name diflunisal, referred to as Dif) was dissolved in 30mL of deionized water, and the pH was adjusted with 2mol / L NaOH solution The value is 10, and the mixed liquid B is obtained. Under vigorous stirring, drop solution A into solution B, N 2 Protection, reaction at 65°C for 48h. The product was filtered, the filter cake was washed and dried in vacuo. The deionized water used in the process was double distilled water.

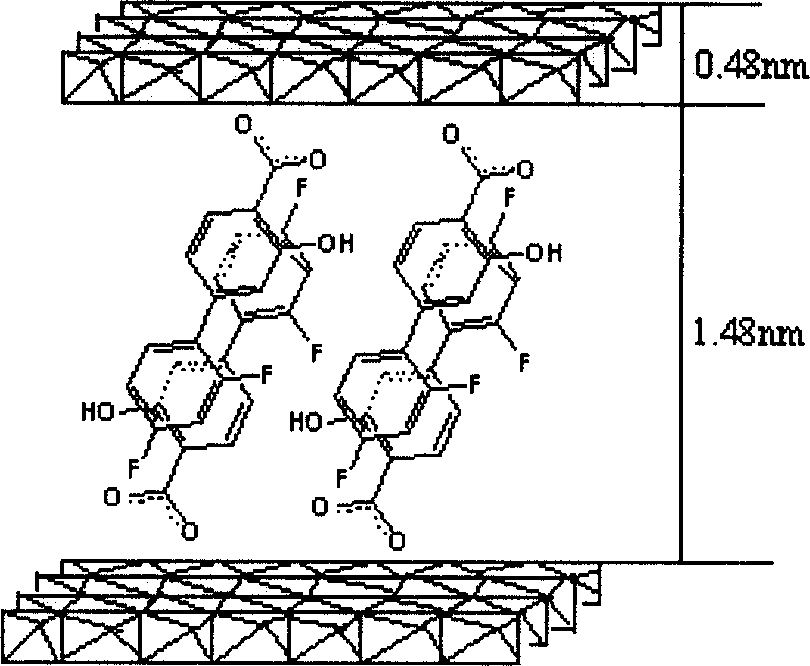

[0045] According to the characterization, the chemical composition of the obtained Dif-LDHs is: Mg 0.70 Al 0.30 (OH) 2 (Dif) 0.30 0.70H 2 O, wherein the content of diflunisal is 49.7%.

Embodiment 2

[0047] (1) Take 11.88g (0.04mol) Zn(NO 3 ) 2 ·6H 2 O and 7.5gAl(NO 3 ) 3 9H 2 O (0.02mol) was dissolved in 100mL deionized water to make solution A; then 4.8g NaOH solid was dissolved in an appropriate amount of deionized water to make 2mol / L solution C; N 2 Under protection, add solution A and solution C dropwise to 100ml of deionized water at a certain drop rate, keep the pH value of the solution between 9 and 10, and continue to stir for half an hour after the dropwise addition. After the obtained slurry was crystallized at 65°C for 18 hours, it was suction-filtered, washed with deionized water until neutral, dried at 65°C, ground, weighed, and stored in a desiccator. denoted as LDHs-NO 3 - .

[0048] (2) Dissolve 1.79g (6mmol) Dif in 30mL deionized water to obtain solution D, and then take 1gLDHs-NO 3 Dissolve in 50mL of deionized water to obtain solution E, under full stirring, mix the two solutions of D and E, adjust pH=10, stir vigorously, N 2 Protection, reac...

Embodiment 3~4

[0052] By the method of embodiment 2, change the pH value in embodiment 2 (2), be respectively 9,11, other operations are with embodiment 2. The deionized water used in the process was double distilled water.

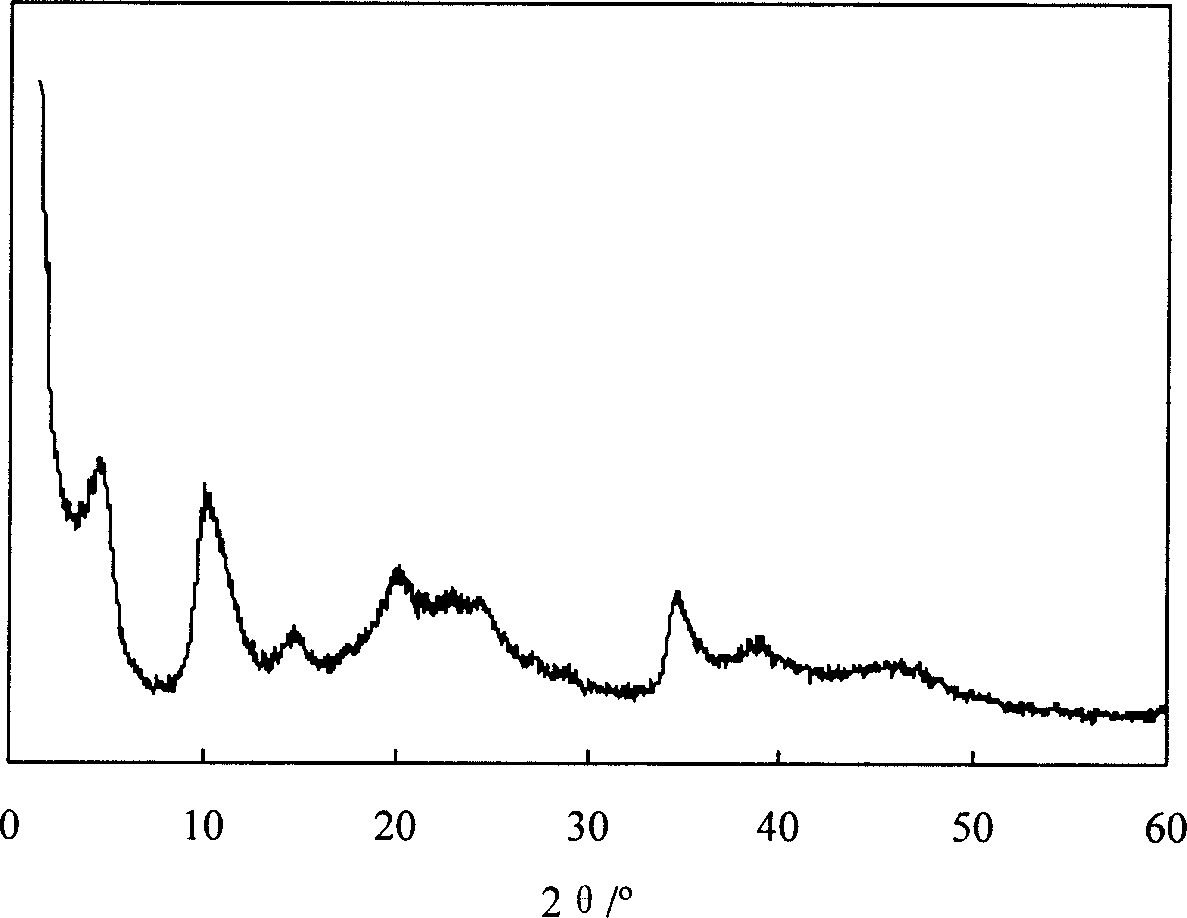

[0053] It was found that at a pH of 10, the obtained Dif-LDHs material has a better crystal structure and represents the d of the interlayer spacing 003 maximum. The specific XRD data are as follows: pH=9, d 003 = 1.91nm; pH = 10, d 003 = 1.96nm; pH = 11, d 003 = 1.84nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com