Heat exchanger and cleaning device with the same

A technology for cleaning devices and heat exchangers, which is applied to water supply devices, water heaters, fluid heaters, etc., can solve the problems of clogging of cleaning nozzles, difficulty in miniaturizing heat exchangers, and difficulty in miniaturizing sanitary cleaning devices, and achieves improved performance. Heat transfer efficiency, reducing the adhesion of impurities, preventing or reducing the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0201] Embodiments of the present invention will be described below with reference to the drawings. However, the present invention is not limited to these embodiments.

[0202] (first embodiment)

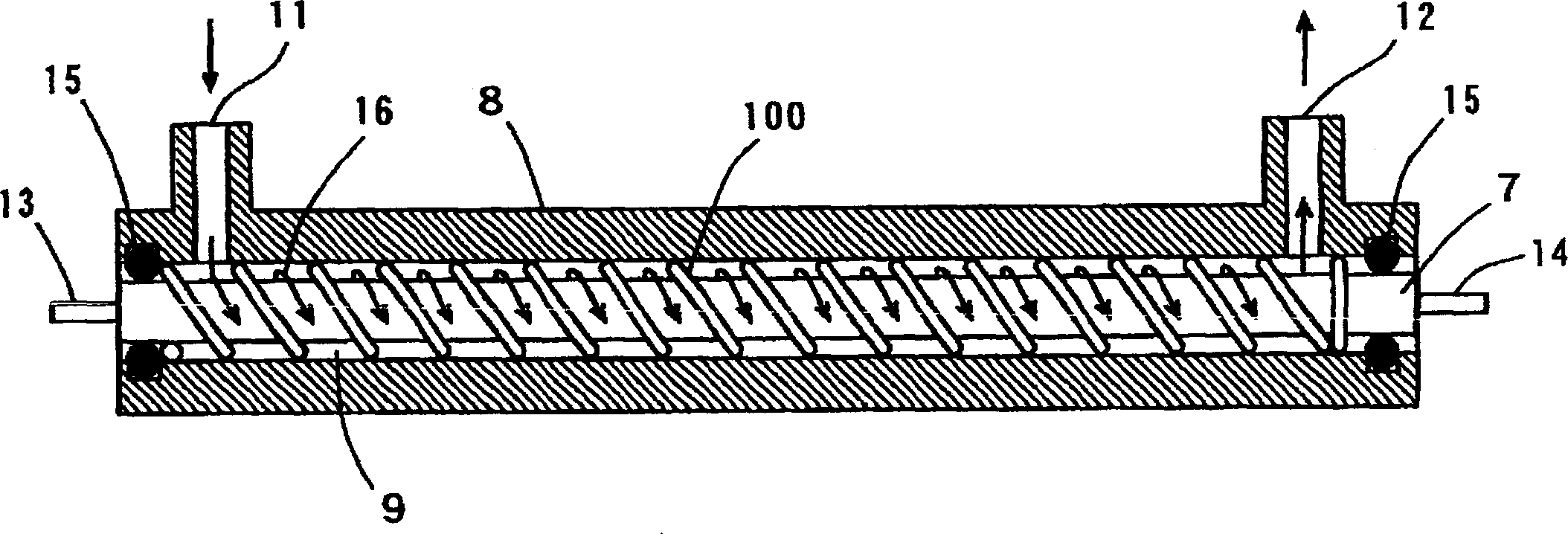

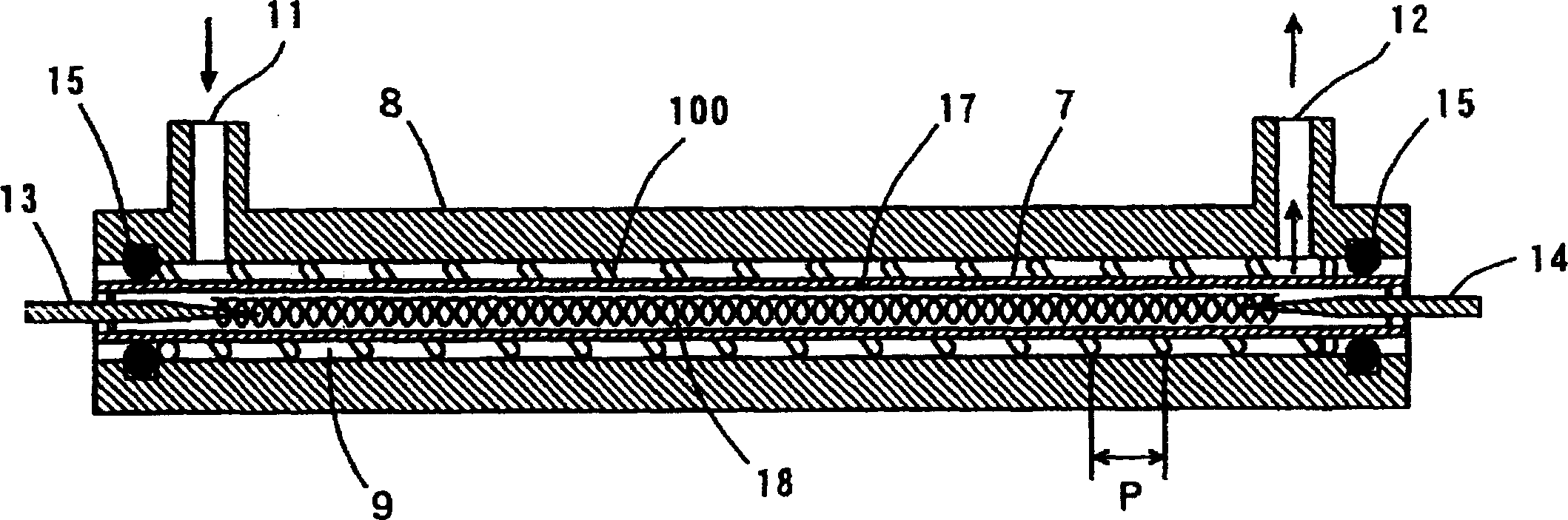

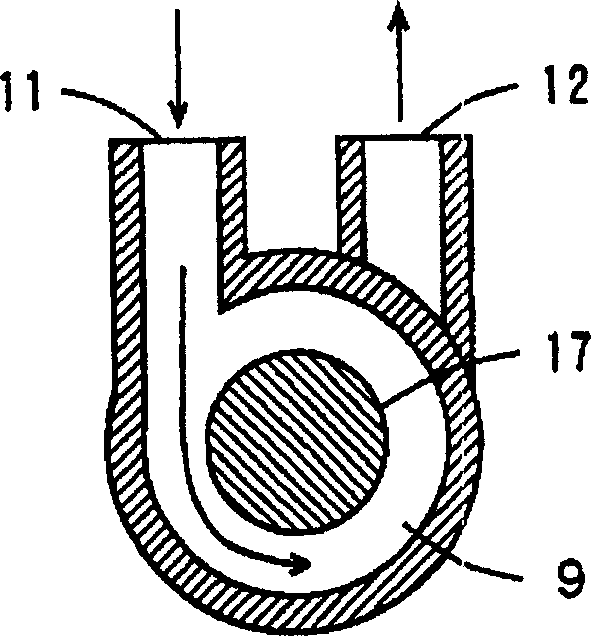

[0203] figure 1 and figure 2 is an axial sectional view of the heat exchanger in the first embodiment of the present invention, figure 1 Indicates the section of the shell and the side of the armored heater, figure 2 Indicates the cross-section of the shell and armored heater. image 3 yes figure 1 and figure 2 Cross-sectional view of the heat exchanger in .

[0204] exist figure 1 Among them, the heat exchanger is composed of a substantially cylindrical sheath heater 7 , a substantially cylindrical casing 8 and a helical spring 100 . The sheath heater 7 is a heating element for heating water as a fluid, and is accommodated in the case 8 . The casing 8 has a hollow with a circular or elliptical cross section, and is provided to surround the outer periphery of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com