Rocket solid propellant burning velocity testing system

A solid propellant and testing system technology, which is applied in fuel oil testing, material inspection products, etc., can solve the problems of low precision, difficulty in obtaining accurate test results, and low testing accuracy, so as to reduce labor intensity, expand the measurement range, and improve testing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

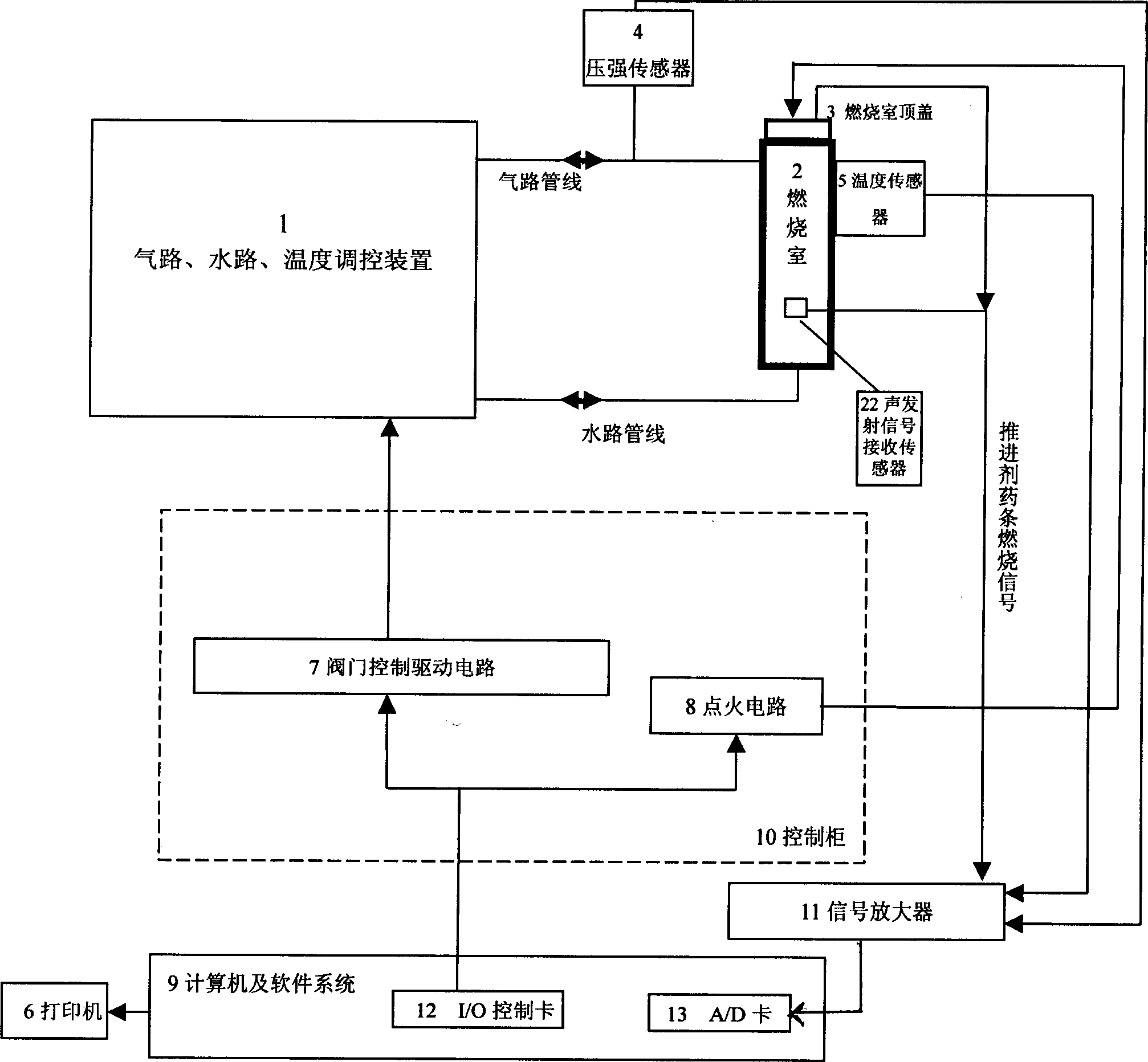

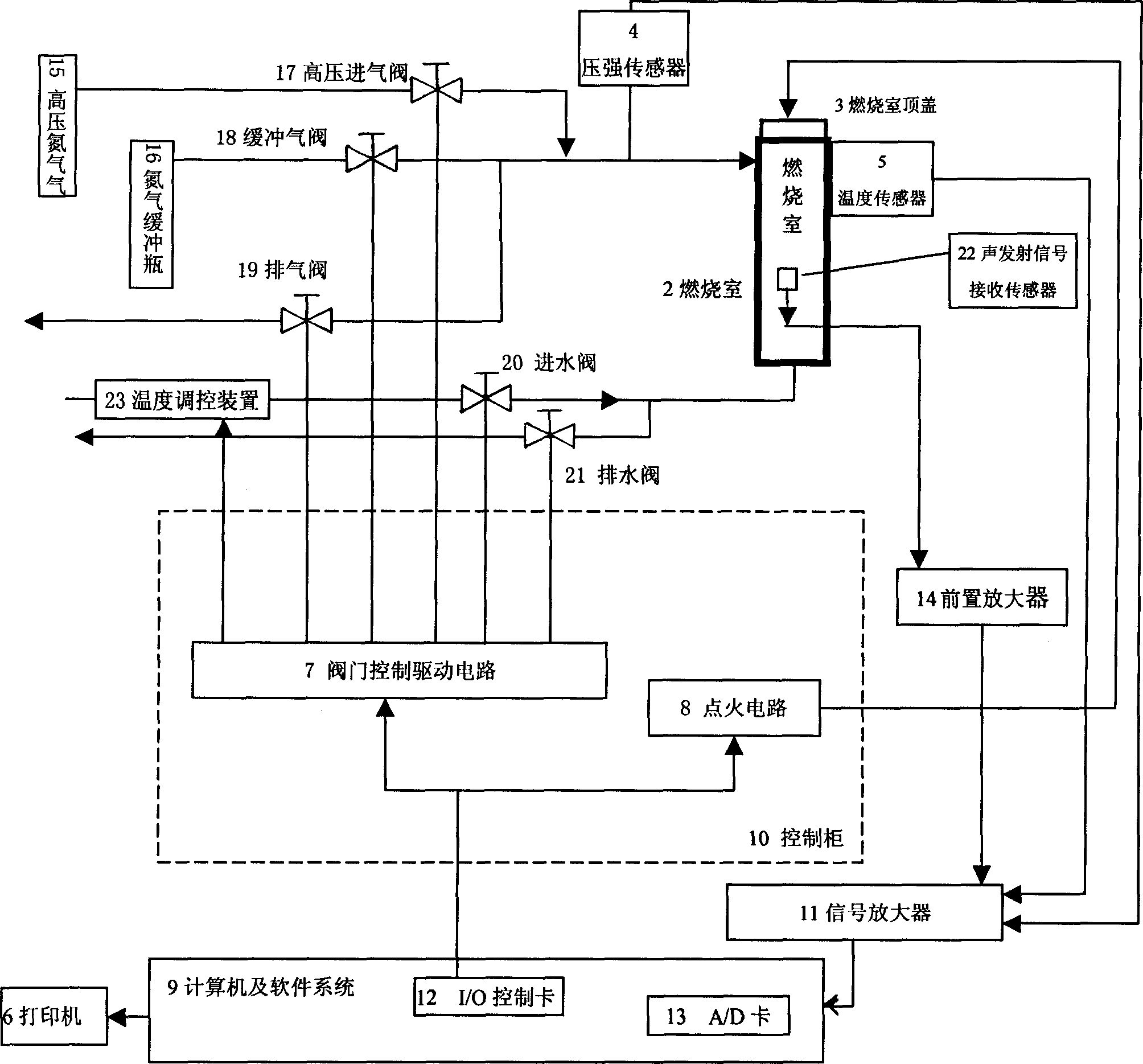

[0015] refer to figure 1 , which is a schematic diagram of the system structure of the present invention, the system is composed of a combustion chamber 2, a signal acquisition device, a gas circuit, a water circuit, a temperature control device 1 and a system control device. The combustion chamber 2 has an inlet / drainage port and an inlet / exhaust port, and the combustion chamber 2 is equipped with a combustion chamber top cover 3 on which copper electrodes are installed. Gas circuit, water circuit and temperature control device 1 have high-pressure nitrogen gas source, buffer nitrogen cylinder, high-pressure inlet valve, buffer gas valve, exhaust valve, water inlet valve, drain valve, temperature control device and corresponding air pipes and water pipes. The signal acquisition device includes a pressure sensor 4 , a temperature sensor 5 , an acoustic emission signal receiving sensor 22 , a copper electrode on the top cover of the combustion chamber 3 , a signal amplifier 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com