Anaerobic active sludge process

An activated sludge, sequencing batch technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of unstable ecosystem, difficult biochemical advantages, and the potential of Methanothrix cannot be fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

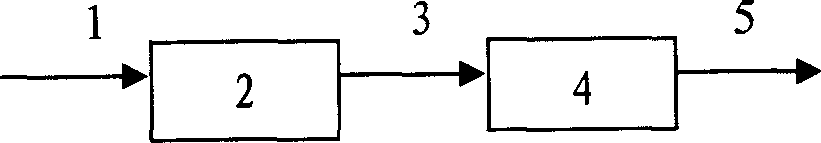

Image

Examples

Embodiment approach 1

[0025] Inoculation sludge is inoculated with digested sludge from urban sewage treatment plants.

[0026] The reactor in section A operates at medium temperature (30-35°C); the adsorption time is 10-15 minutes; the biogas (biogas) produced by itself is used for intermittent stirring; the reactor in section A is maintained at a high concentration of acetic acid, and the organic load of the influent is about 5.0~ 7.5g / (L d); trace metal elements have an activation effect on Methanosarcina bacteria, and the trace elements Fe, Co, Ni are directly added to the reactor, and the trace element dosage is: Fe adopts 1mg / ( L·d); Co adopts 0.1mg / (L·d); Ni adopts 0.2mg / (L·d). Reactor height and diameter ratio H / D take 5.

[0027] The B-stage reactor operates at medium temperature (30-35°C); the biodegradation time is 6h-8h; the biogas (biogas) generated by the A-stage reaction is used for intermittent stirring; the load of the B-stage reactor is maintained at 5g / (L·d) Next, make it opera...

Embodiment approach 2

[0029] Inoculation sludge is inoculated with digested sludge from urban sewage treatment plants.

[0030] The reactor in section A operates at medium temperature (30-35°C); the adsorption time is 10-20 minutes; the biogas (biogas) produced by itself is used for intermittent stirring; the reactor in section A is maintained at a high concentration of acetic acid, and the organic load of the influent is 7.5~ Between 10.0g / (L d); trace metal elements have an activation effect on Methanosarcina bacteria, and the trace elements Fe, Co, and Ni are directly added to the reactor, and the trace element dosage is: Fe is 1mg / (L·d); 0.1 mg / (L·d) for Co; 0.2 mg / (L·d) for Ni. The reactor height and diameter ratio H / D is preferably 6.

[0031] The B-stage reactor operates at medium temperature (30-35°C); the biodegradation time is 8h-12h; the biogas (biogas) generated by the A-stage reaction is used for intermittent stirring; the load of the B-stage reactor is maintained at 5g / (L·d) Next, ...

Embodiment approach 3

[0033] Inoculation sludge is inoculated with digested sludge from urban sewage treatment plants.

[0034] The reactor in section A operates at medium temperature (30-35°C); the adsorption time is 15-30 minutes; the biogas (biogas) produced by itself is used for intermittent stirring; the reactor in section A is maintained at a high concentration of acetic acid, and the organic load of the influent is 10.0~ Between 12.0g / (L·d); trace metal elements have an activation effect on Methanosarcina bacteria, and the trace elements Fe, Co, and Ni are directly added to the reactor, and the trace element dosage is: Fe is 1mg / (L·d); 0.1 mg / (L·d) for Co; 0.2 mg / (L·d) for Ni. Reactor height and diameter ratio (H / D) take 5.5.

[0035] The B-stage reactor operates at medium temperature (30-35°C); the biodegradation time is 12h to 24h; the biogas (biogas) generated by the A-stage reaction is used for intermittent stirring; the load of the B-stage reactor is maintained at 5g / (L·d) Next, make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com