Biological material film with porous structure and its prepn

A technology of biomaterials and porous structures, applied in medical science, prostheses, etc., can solve the problems of membrane exposure, influence, lack of active induction of differentiation and growth promotion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Dissolve 10g of polyamide 66 in 100ml of ethanol at 70-80°C with stirring and the action of catalyst calcium chloride to obtain a film-forming liquid of polyamide 66. After the film-forming liquid is cooled to 30-40°C, dissolve about 1.5ml Pour the film-forming solution onto a glass plate with a diameter of 12 cm to spread freely to form a film, dry at 70°C, mark the front and back with a marker pen, soak and wash it with 200ml deionized water for several times, and check that there is no chloride ion in the eluent with 1M silver nitrate solution (each soaking time is greater than 30 minutes), and dried at 70°C to obtain the polyamide 66 porous biofilm of the present invention.

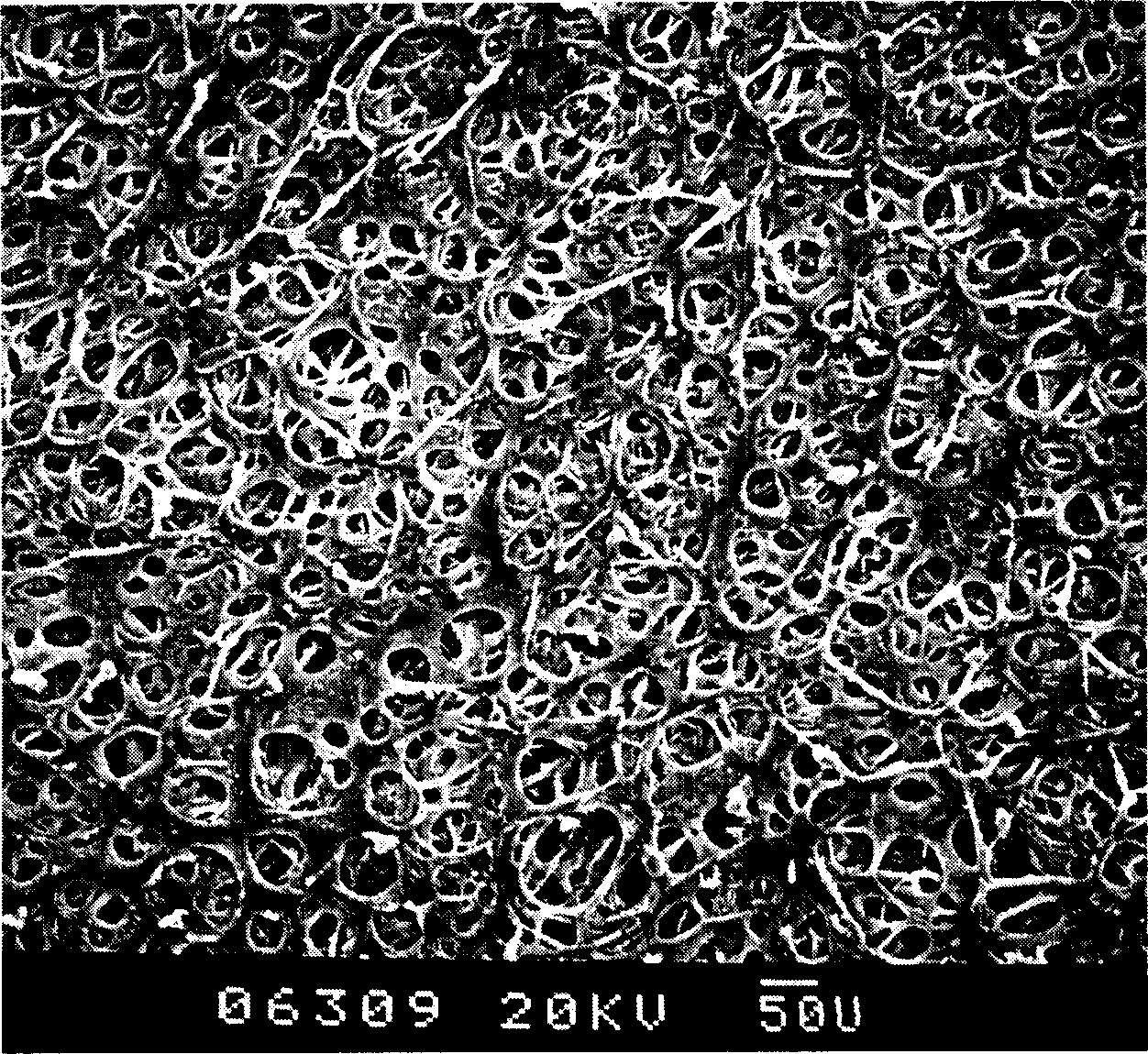

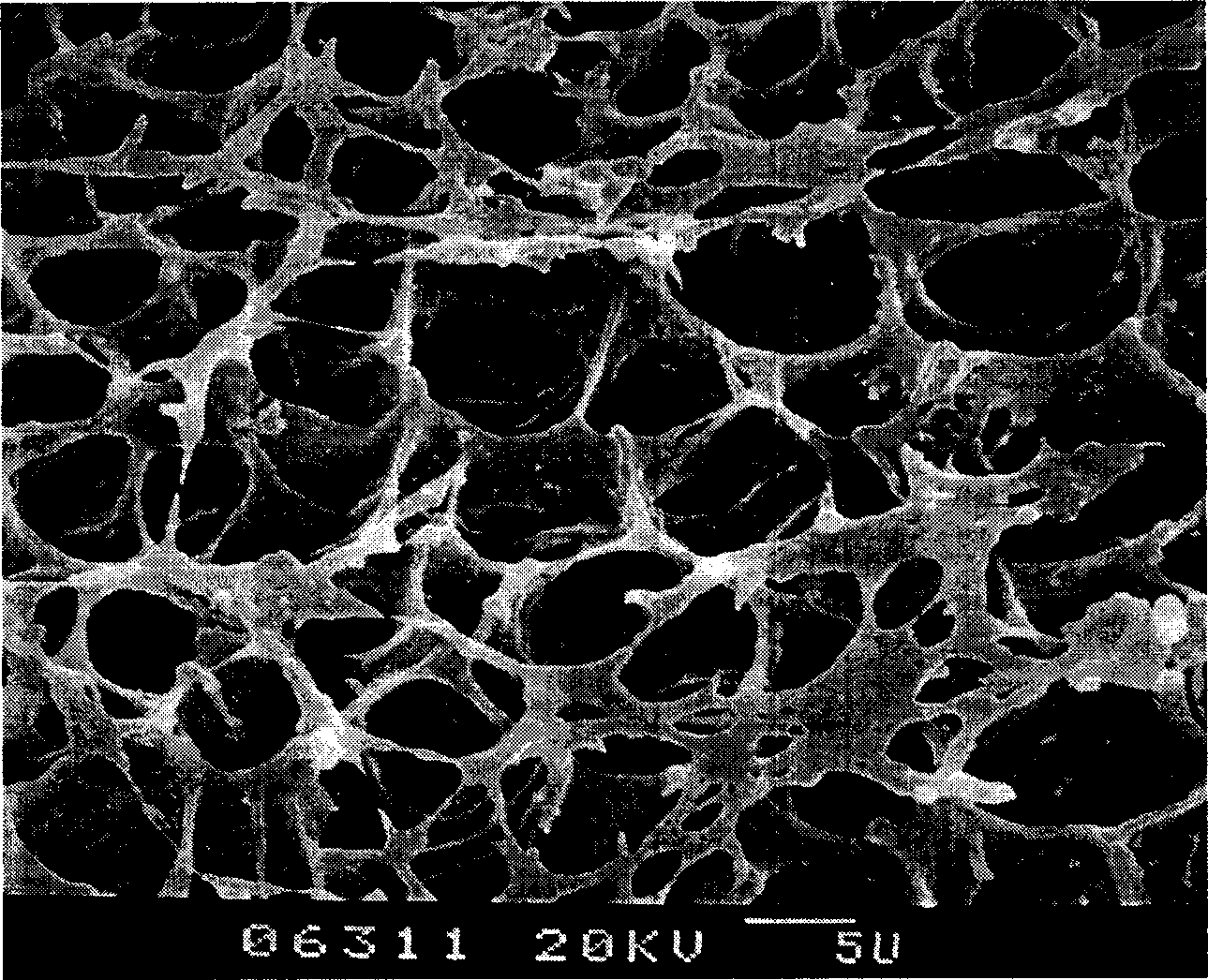

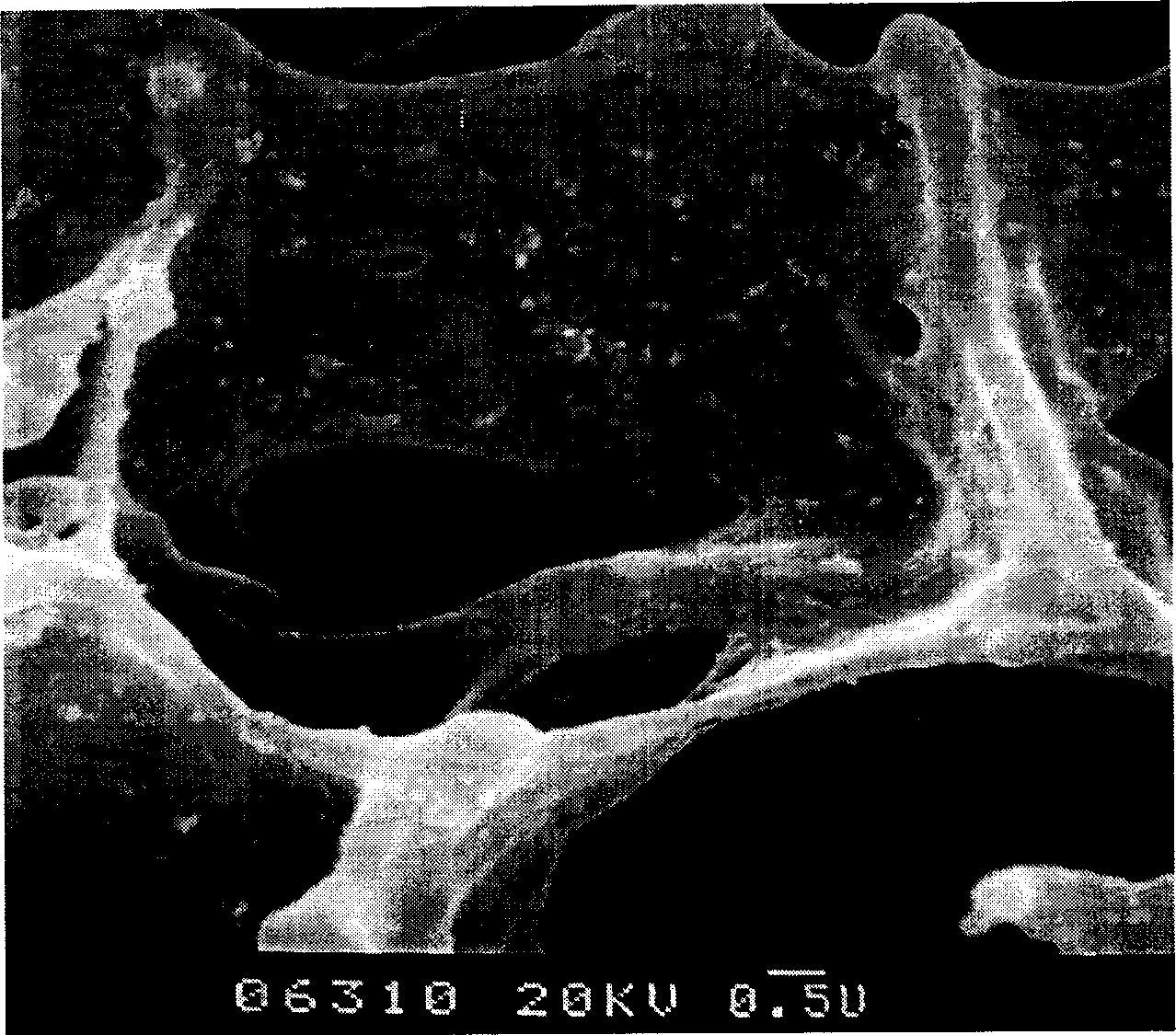

[0043] The prepared polyamide 66 membrane has a porous structure, and the pores are interconnected with each other. The average pore diameter is about 60-70 μm, and the structure is as follows: figure 1 shown. The thickness of the porous membrane was 0.1 mm as measured with a vernier caliper....

Embodiment 2

[0045]Dissolve 20g of polyamide 66 in 100ml of ethanol at 70-80°C with stirring and the action of catalyst calcium chloride to obtain a film-forming liquid of polyamide 66. After the film-forming liquid is cooled to 30-40°C, dissolve about 2.5ml Pour the film-forming solution onto a glass plate with a diameter of 12 cm and spin to form a film, dry at 60°C, mark the front and back with a marker pen, soak and wash it with 200ml deionized water for several times, and check that there is no chloride ion in the eluent with 1M silver nitrate solution (each soaking time is greater than 30 minutes), and dried at 70°C to obtain the polyamide 66 porous biofilm of the present invention.

[0046] The prepared polyamide 66 membrane has a porous structure, the pores communicate with each other, and the average pore diameter is about 50-70 μm. The thickness of the porous membrane was measured with a vernier caliper to be 0.2 mm.

Embodiment 3

[0048] Dissolve 10g of polyamide 6 in 100ml of ethanol at 70-80°C with stirring and the action of catalyst calcium chloride to prepare a film-forming solution of polyamide 6. After the film-forming solution is cooled to 30-40°C, dissolve about 2ml of The membrane solution was poured onto a glass plate with a diameter of 12 cm to spread freely to form a membrane, dried at 70°C, marked with a marker pen on the front and back sides, soaked and washed several times with 200ml deionized water, and tested for the absence of chloride ions in the eluent with 1M silver nitrate solution ( The soaking time is greater than 30 minutes each time), and dried at 70°C to obtain the polyamide 6 porous biofilm of the present invention.

[0049] The prepared polyamide 6 membrane has a porous structure, the pores communicate with each other, and the average pore diameter is about 60-70 μm. Measured with a vernier caliper, the thickness of the porous membrane was 0.12 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com