Loose sheath type wire handle

A holding part, loose-sleeve technology, applied in the direction of maintaining the distance between parallel conductors, mechanical vibration damping devices, etc., can solve the problems of increased projected cross-sectional area, increased wind pressure load, complex structure, etc., and achieves improved aging characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] An embodiment of the loose sleeve type electric wire holding part of the present invention will be described in detail below with reference to the accompanying drawings.

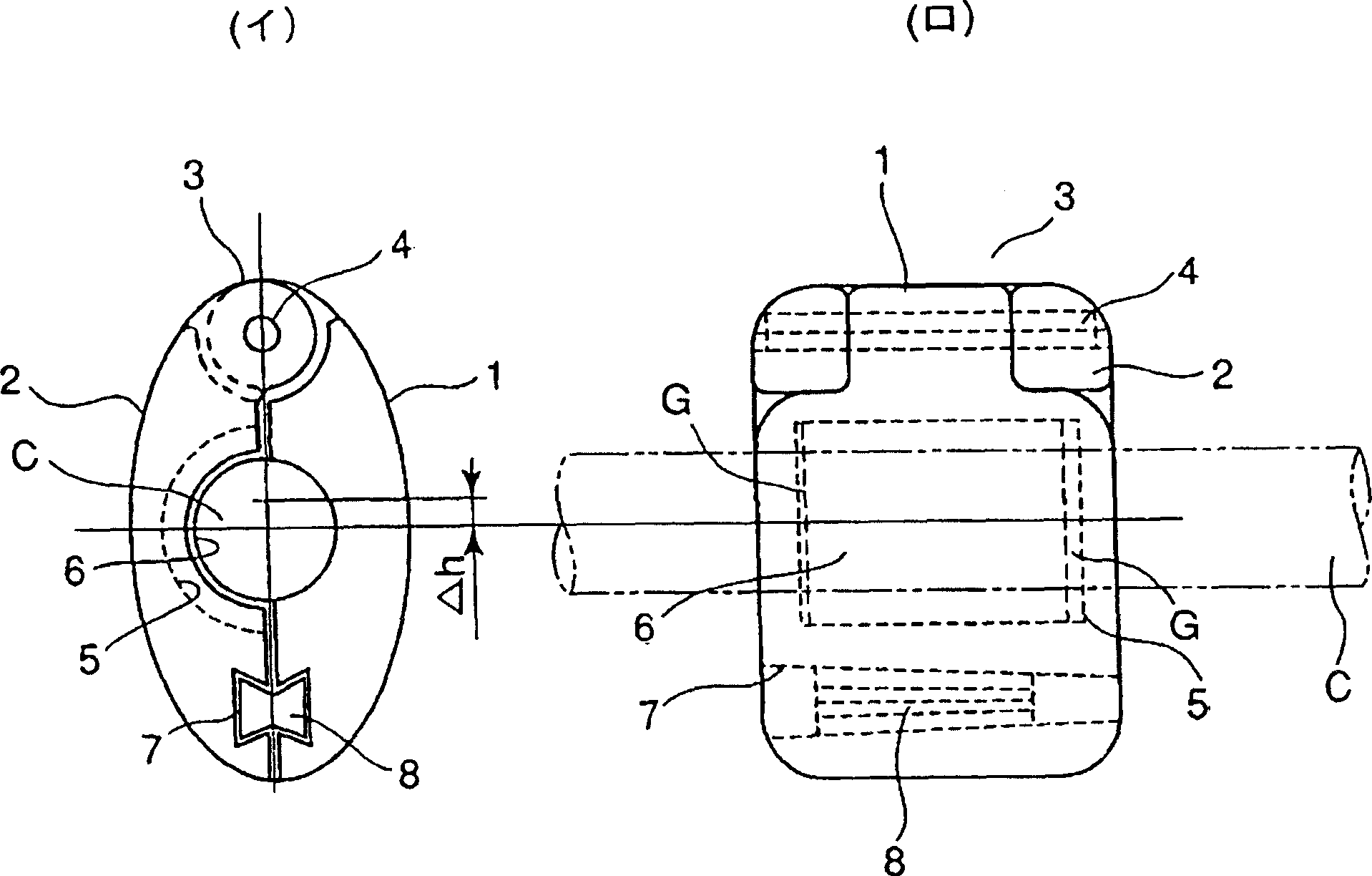

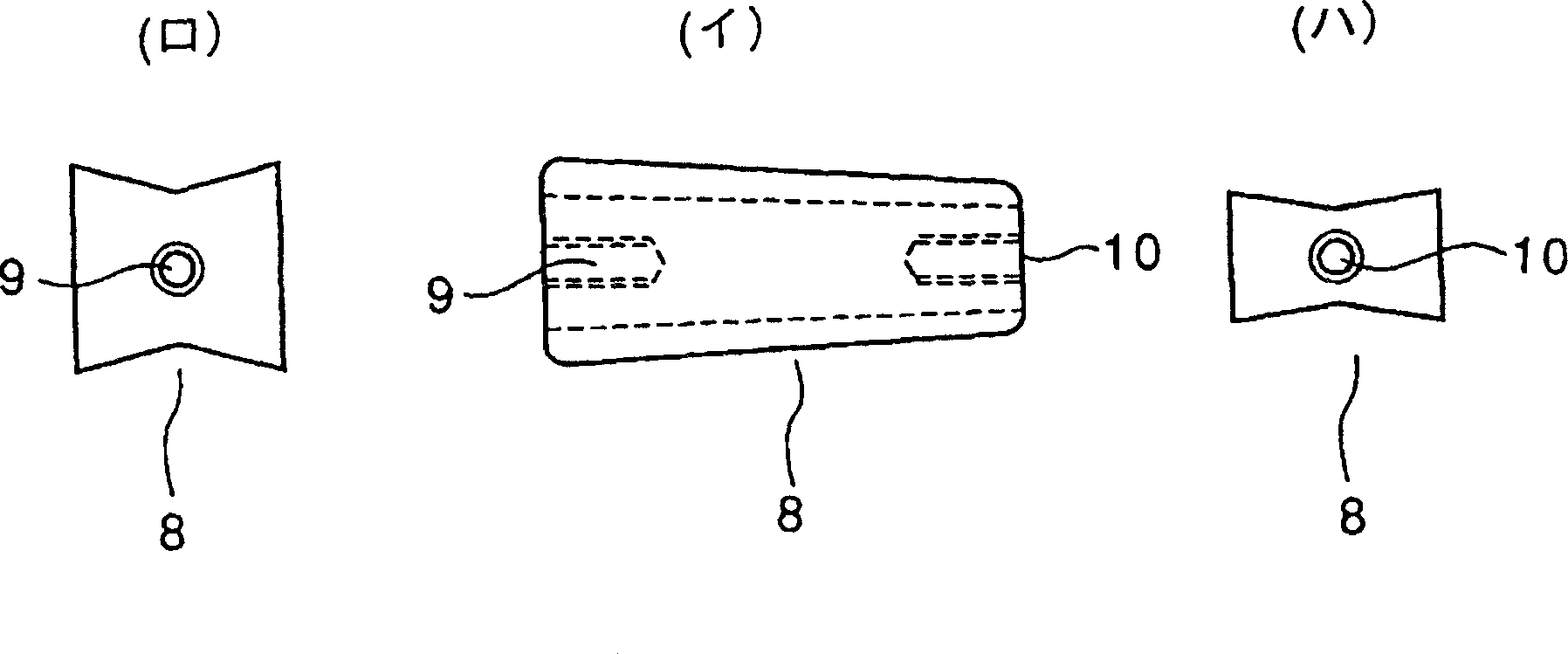

[0037] figure 1 It is a front view (□) and a side view (□) of a fixed ring binder which is a constituent part of the loose sleeve grip part of the present invention. exist figure 1 Among them, a hinge mechanism 3 is provided on one end of the fixed ring clamps 1 and 2, which can be freely opened and closed with the pin 4 as the axis. On one side 2 of the fixed ring binder, a receiving groove 5 for installing a resilient rubber-like elastic body ring 6 is formed. In addition, gaps (G) that are slightly longer than the length of the rubber-like elastic body ring 6 are provided on both sides in the longitudinal direction of the receiving groove 5 . The reason for this is that the coefficient of volume expansion of rubber or the like is one digit larger than that of aluminum or the like, and when the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com