Pneumatic boost serial loose hinge flexible multi-finger claw

A technology of loose-leaf hinges and multi-finger claws, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of reducing angular displacement, insufficient pressure, and small slope of the curve, etc., to achieve reliable grasping and good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below is working principle and working process of the present invention:

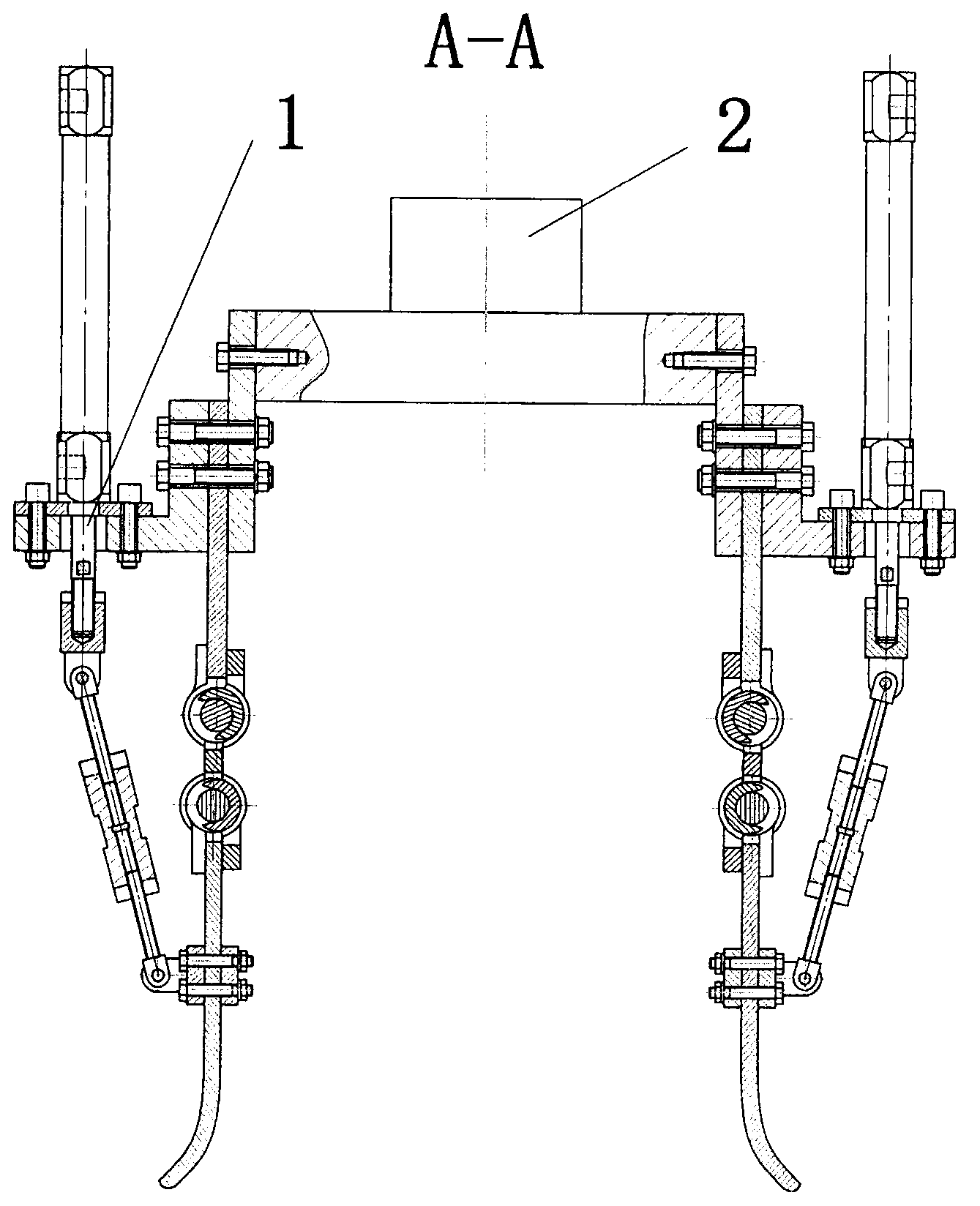

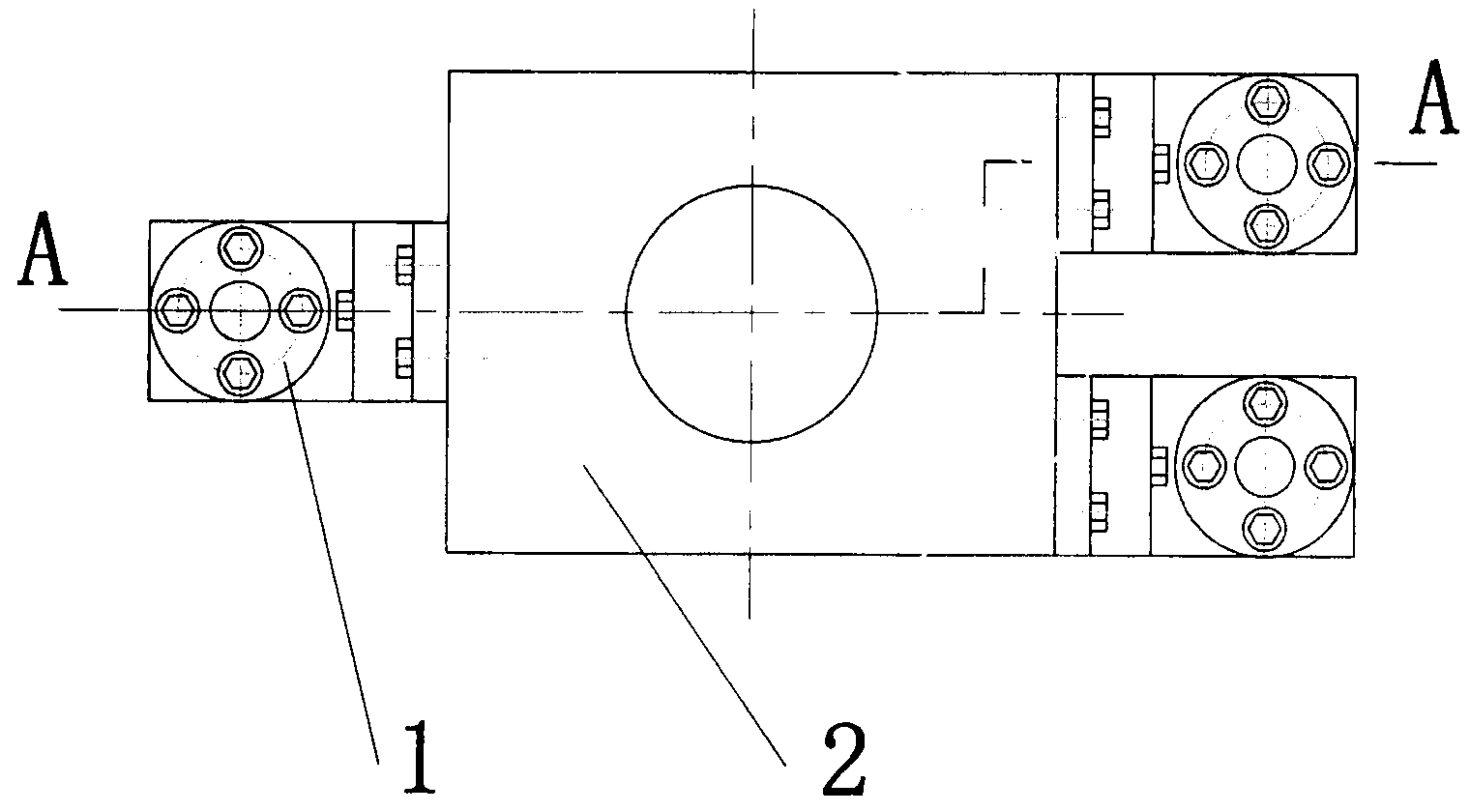

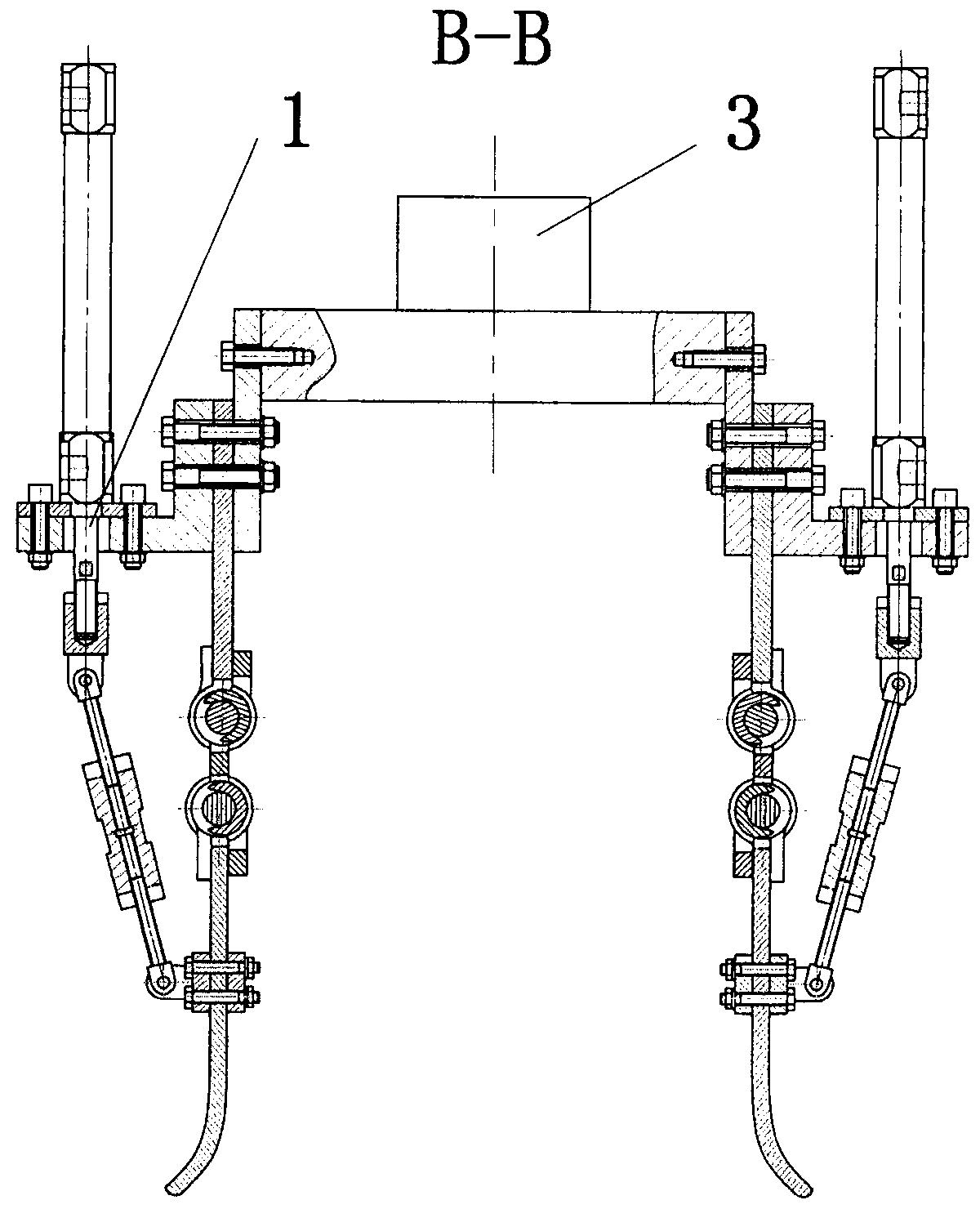

[0022] Such as figure 1 , 2 As shown, according to the long and rectangular complex objects, after experimental research and theoretical analysis, adjust the length of the two force rods (composed of the left threaded hinge rod 9a, the threaded sleeve 10a, and the right threaded hinge rod 11a), and then adjust the pressure plate 7a and the hinge Bearing 8a is fixed on the appropriate position of loose-leaf under serial hinge 5a. The lowermost end of the lower hinge of the series hinge 5a is a curved surface segment, and the grasping of complex objects just contacts the curved surface segment of the lower hinge of the serial hinge 5a. After the characteristic parameters and pre-tightening angles of the large torsion spring 4a and the small torsion spring 6a are optimized, the coordination of a total of four angular displacements at the two hinges of the two hinges (supports) and the series loose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com