Reef blasting method in underwater complex geological condition

A technology of complex geology and reef rocks, applied in blasting and other directions, can solve problems such as poor blasting effect, inability to charge powder, and difficult operation, so as to avoid difficulties and dangers, wide use range, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] High-pressure gas or high-pressure water flushing method, the steps include:

[0037] a) Positioning: position the reef blasting workboat or working platform according to the designed position;

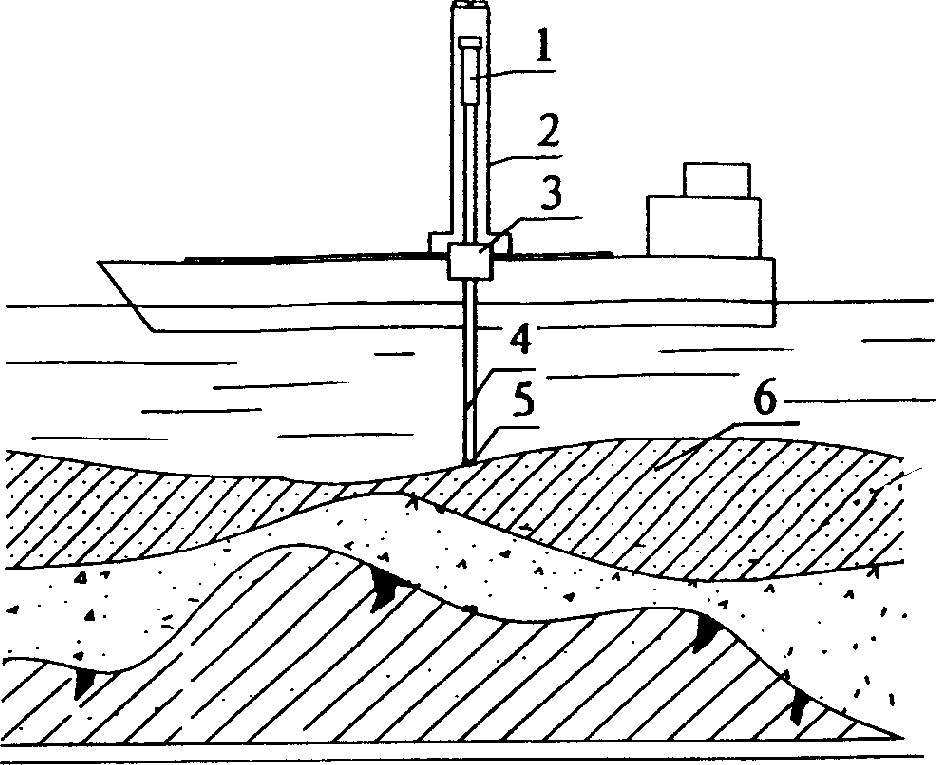

[0038] b), scour the covering layer and the gravel layer; the drill pipe 4 with the drill bit 5 is lowered to the covering layer and the crushed stone layer 6 surfaces by the rotary head 1 on the drilling rig 2, such as Figure 1A As shown, utilize high-pressure gas or high-pressure water, through the through hole on the drilling rod 4 end drill bit 5 that is connected on the drilling rig 2, the covering layer on the reef, the gravel layer 6 are washed away until the reef surface is exposed, as shown in FIG. Figure 1B shown;

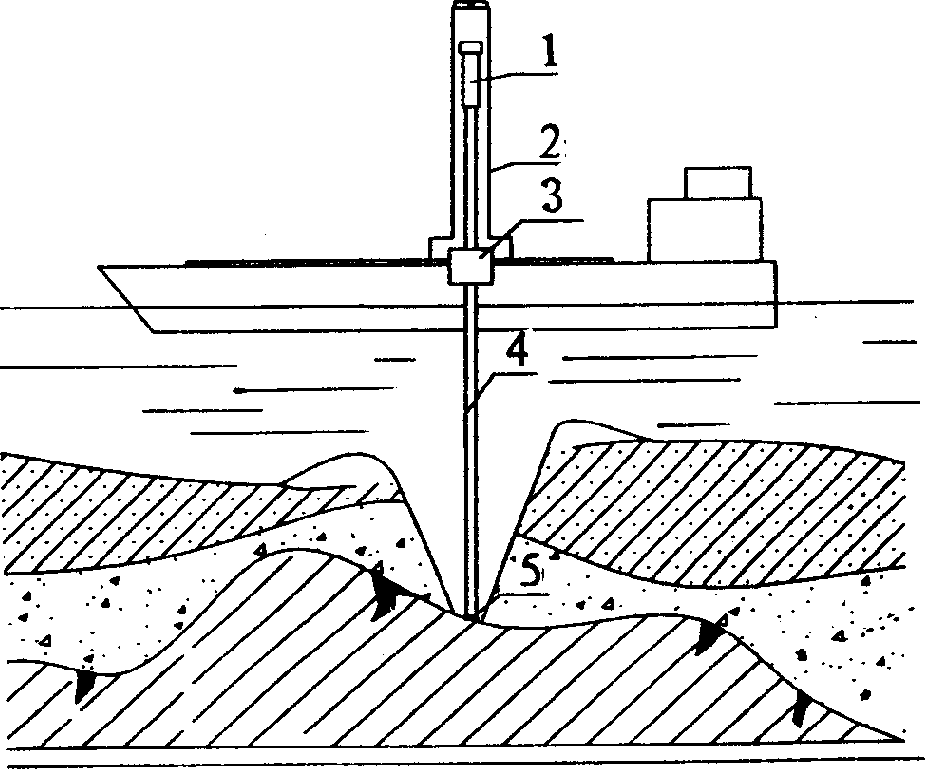

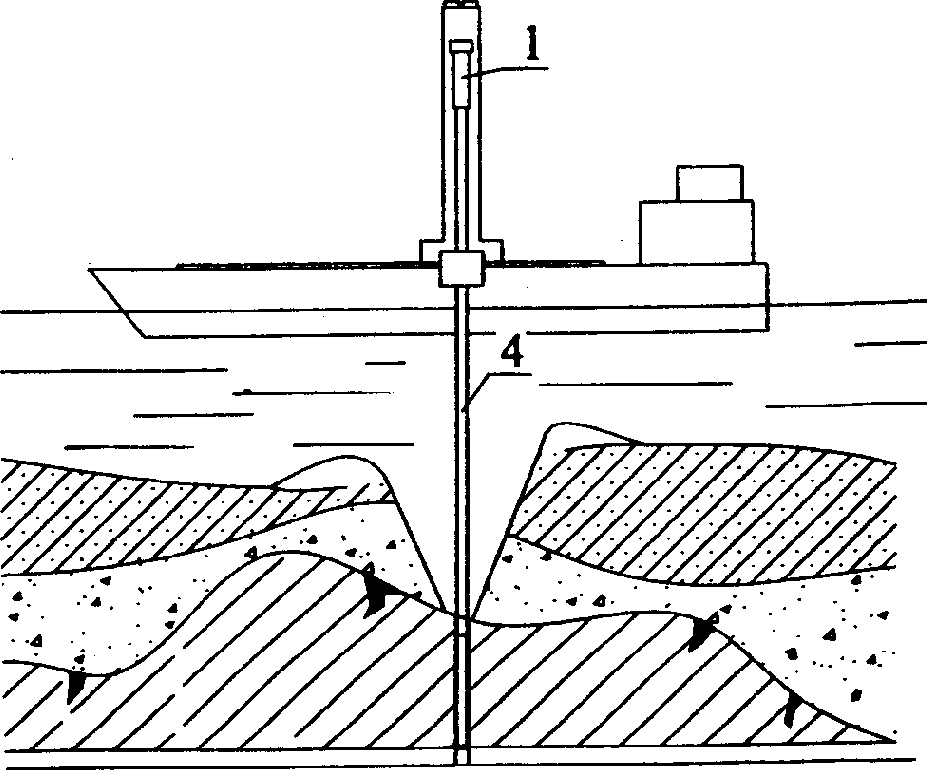

[0039] c), drilling: the rotary head 1 on the drilling rig 2 drives the drill pipe 4 with the drill bit 5 to drill to the design depth on the reef surface, such as Figure 1C shown;

[0040] d), Casing: At this time, the rotary head 1 on the drilling ...

Embodiment 2

[0047] The casing follow-up method, the steps include:

[0048] a) Positioning: position the reef blasting workboat or water work platform according to the designed position;

[0049] b), special tool positioning: place the bottom of the special tool and the central drill bit 18 on the combined drill pipe 13 in the outer casing on the covering layer and the crushed stone layer 6, and use the clasp 3 on the casing frame to place the outer casing 12 is fixed on the side of the workboat or the work platform or the front side of the drilling rig, as shown in Figure 2A;

[0050] c), drilling: the rotary head 1 on the drilling machine 2 drives the rod stabilizer 14 on the combined drill rod 13, the eccentric wheel 16 with the cutter head 17, and the center drill bit 18 to drill holes. Eccentric wheel 16 expands, as image 3As shown, at this time, the bore diameter is greater than the outer diameter of the outer casing 12, and the rod stabilizer 14 drives the pipe shoe 15 and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com