Grille type connection method of rigid joint for underground continuous wall

A grid-type diaphragm wall and underground diaphragm wall technology, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problem of reducing the anchoring effect of cross steel plates and II sequence groove concrete, difficulty in removing joint boxes, and complicated construction procedures, etc. problems, to achieve the effect of mature construction technology, guaranteed construction quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be more readily understood by reference to the following examples, which are given to illustrate the invention and not to limit the scope of the invention.

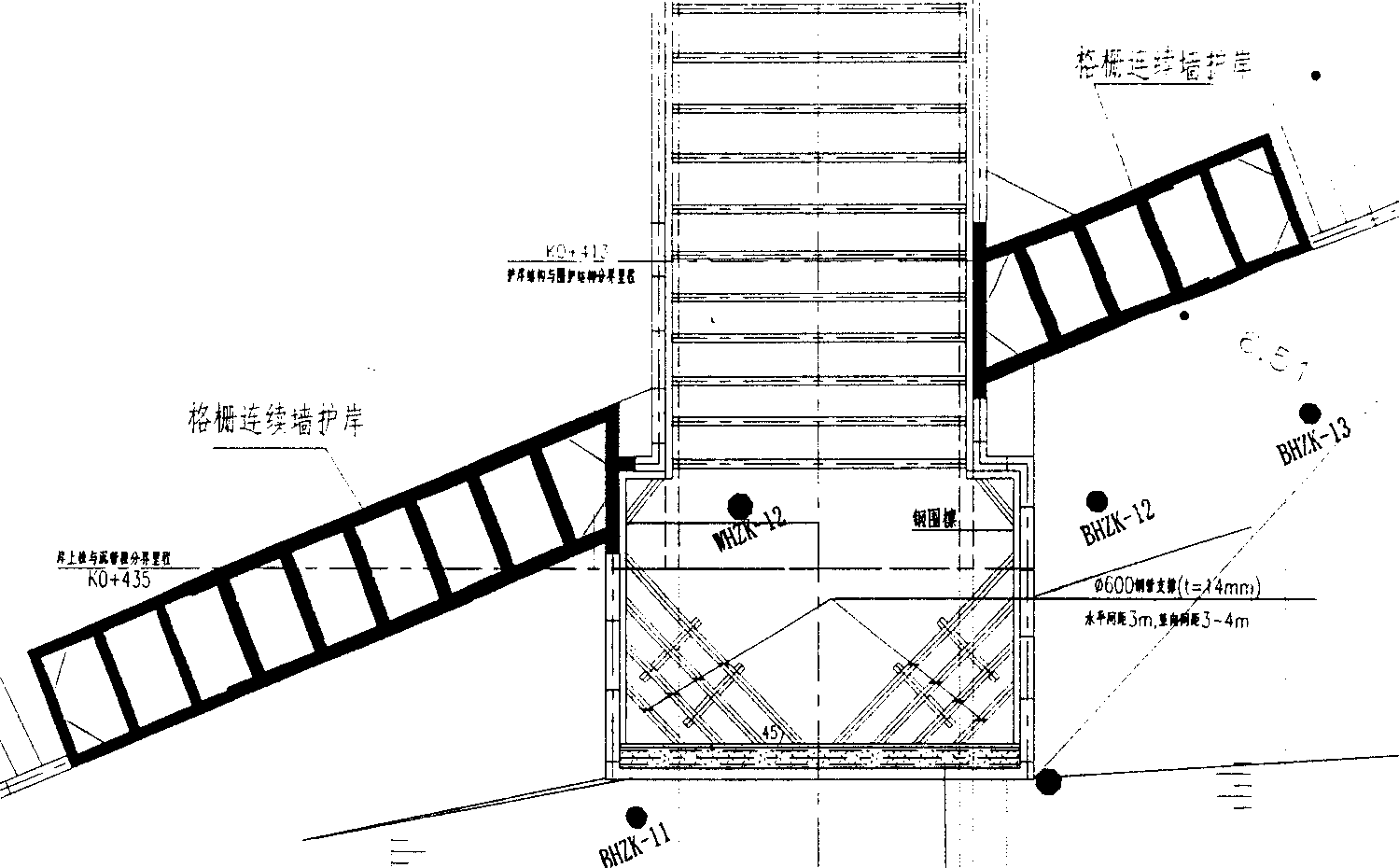

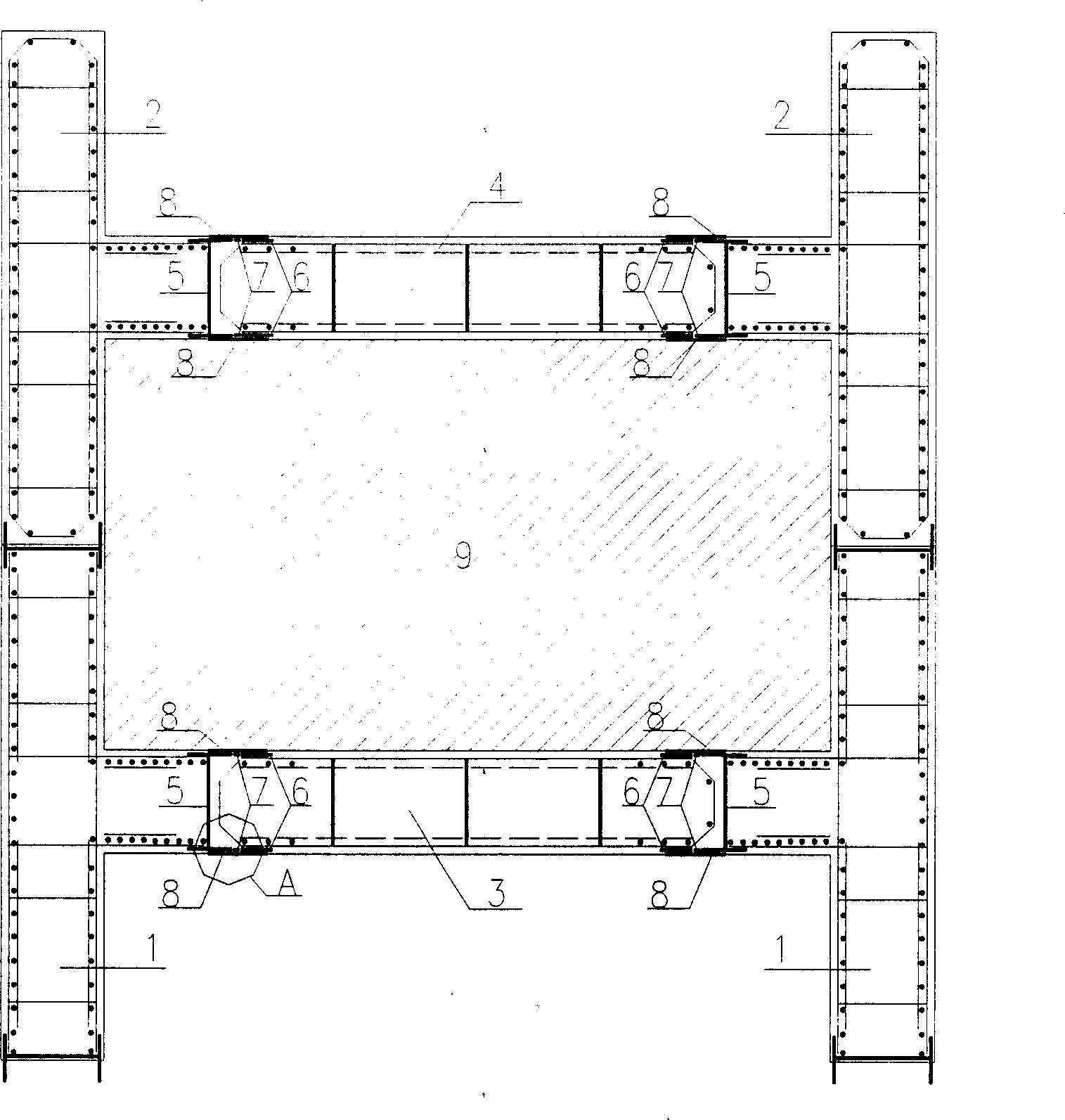

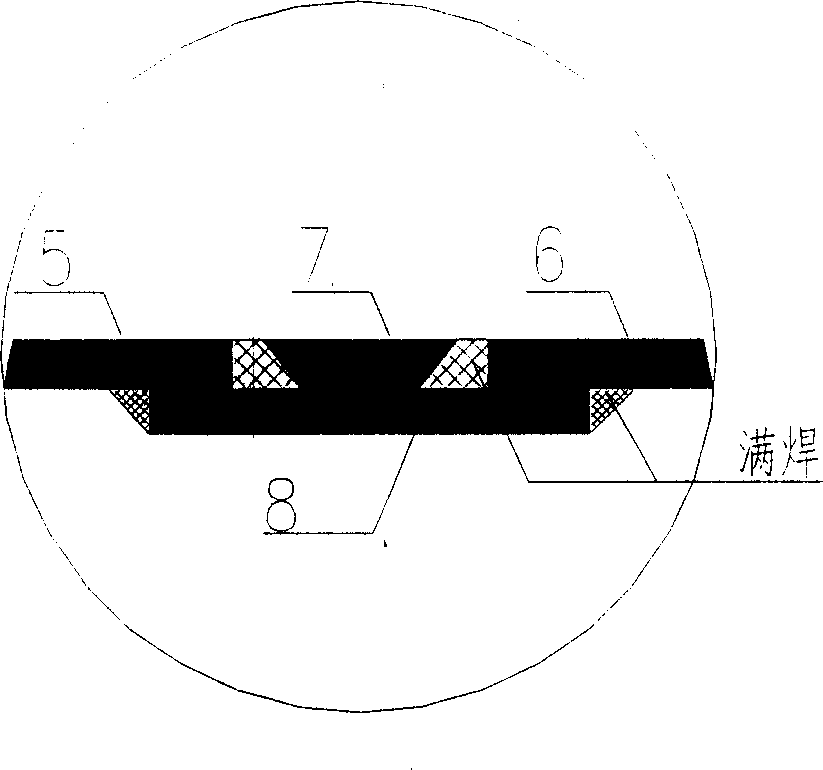

[0021] 1. Project overview

[0022] Guangzhou Luntou Biological Island Tunnel is located in the southeast of Guangzhou City, connecting the southern expressway and the biological island. The tunnel line runs in a north-south direction. The starting point of the project design is located in Luntou Village, Haizhu District, connecting the southern expressway and the extension of Keyun Road, passing through the Luntou Sea in the middle, and the design end point is on the biological island. The total length of the route is 1111.18 meters. The project is a two-way four-lane municipal cross-river highway tunnel. The middle section of the river is constructed by the immersed tube method, and the upper sections on both sides of the bank are constructed by the open cut method.

[0023] When excav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com