Porous polypropylene particle suspension solid phase graft-modification method

A technology of suspension grafting and solid phase grafting, which is applied in the field of porous polypropylene particle suspension solid phase grafting modification, can solve the problem of unsuitable monomers with large solubility, low grafting depth, reactants and The product is difficult to separate and other problems, and the effect of no pollution, simple process and improved mechanical properties is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

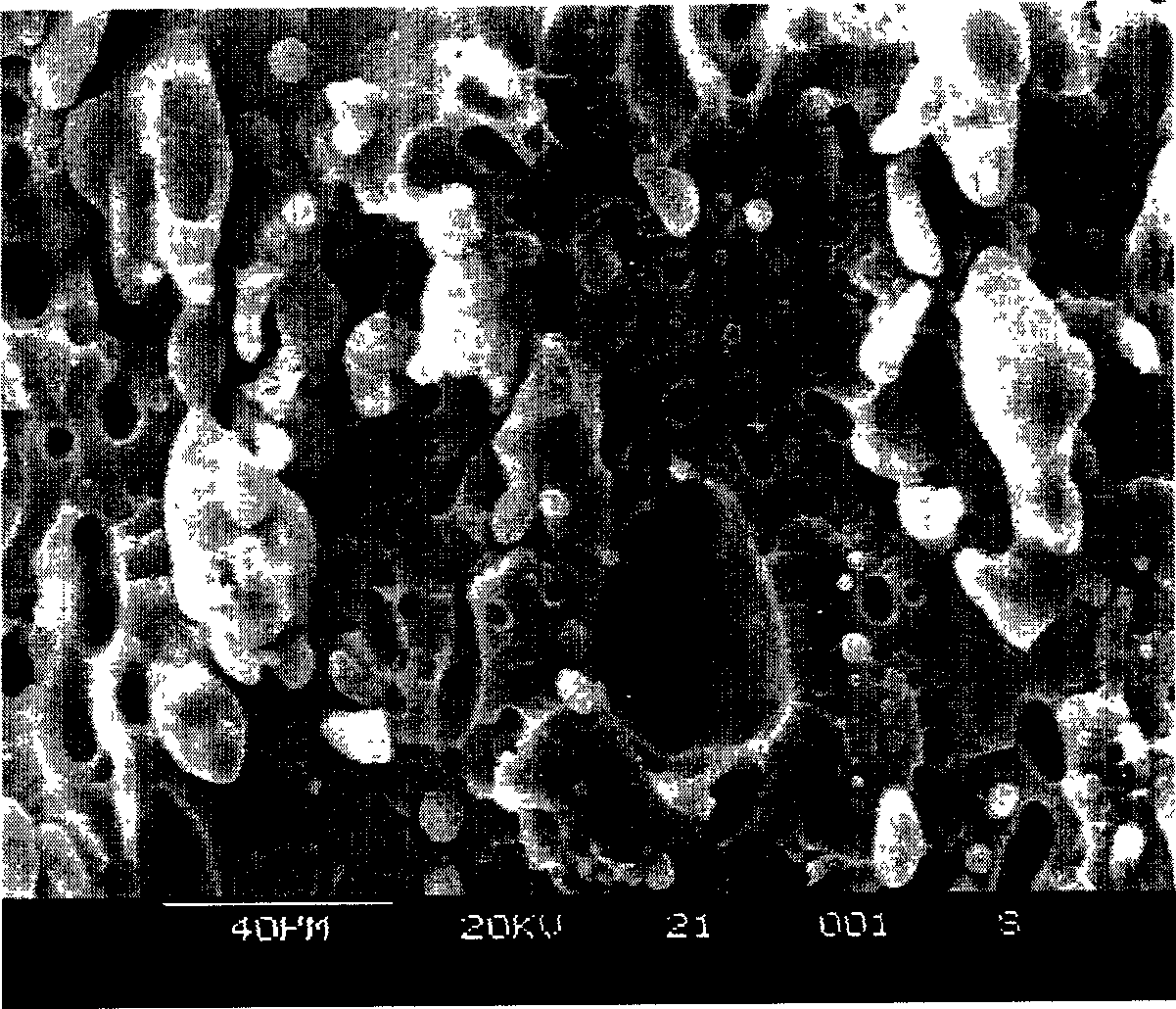

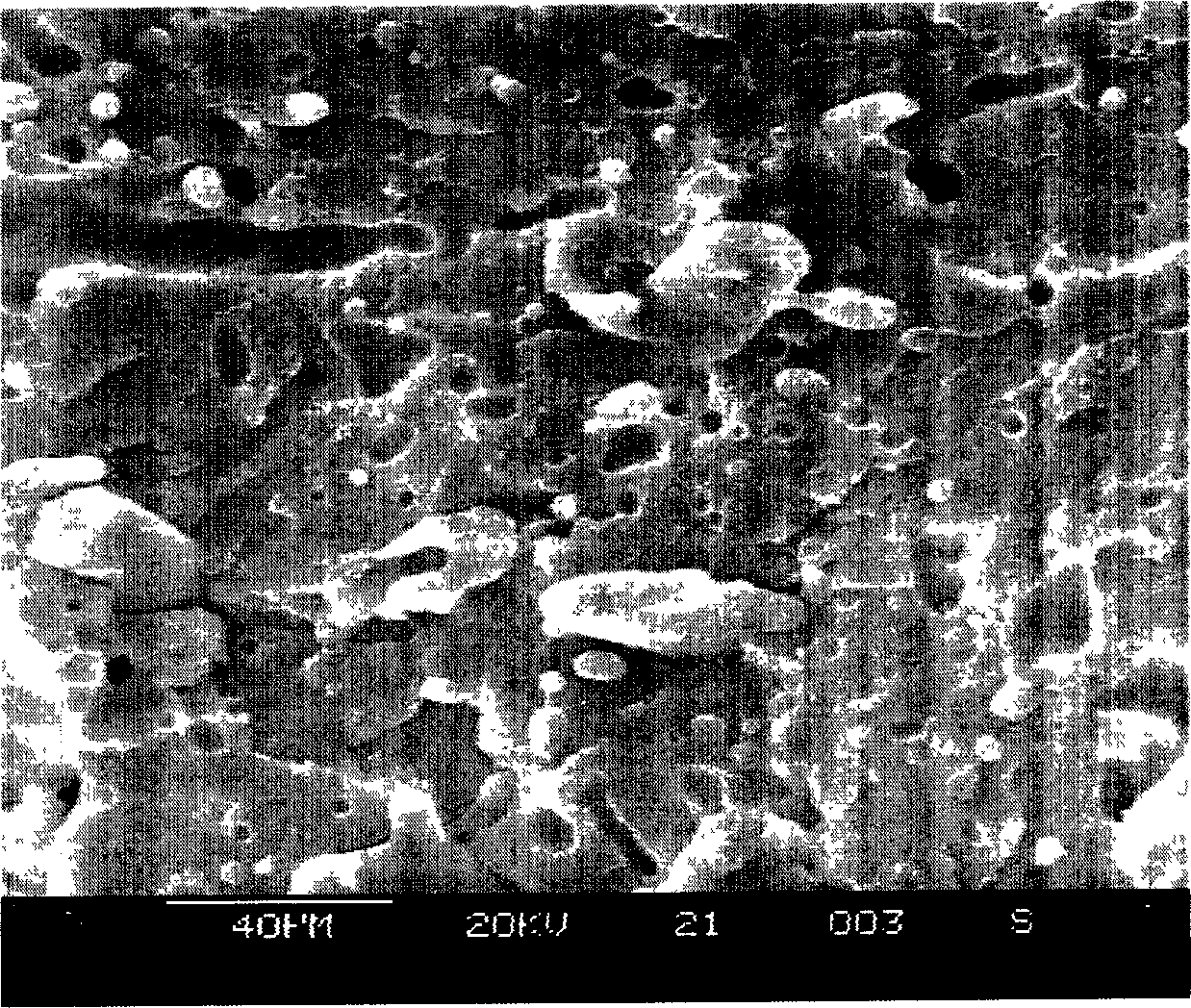

Image

Examples

Embodiment 1

[0030] Dissolve the initiator benzoyl peroxide in the acrylic acid monomer according to 0.5% of the mass of the monomer, and then soak the porous polypropylene (PP) particles with a porosity of 0.14-0.44 in the above-mentioned monomer / initiator solution for 30 Minutes, so that monomers and initiators are fully adsorbed into the pores of PP particles. Prepare sodium chloride brine with a concentration of 20%, put it in the reactor, turn on the stirring and heating device, and when the temperature reaches 85°C, put in PP particles soaked in monomer and initiator, react for 2 hours, and discharge , washed with distilled water and acetone to remove unreacted monomers and initiators, and then dried to obtain a graft-modified product.

Embodiment 2

[0032] Dissolve the initiator benzoyl peroxide in the methyl acrylate monomer according to 1% of the monomer mass, and then soak the porous polypropylene (PP) particles with a porosity of 0.14-0.44 in the above monomer / initiator solution For 20 minutes, the monomer and initiator are fully absorbed into the pores of PP particles. Prepare brine with a concentration of 35% sodium chloride, place it in the reactor, and turn on the stirring and heating device. When the temperature reaches 85°C, put PP particles soaked in monomers and initiators, react for 3 hours, discharge, wash with distilled water and acetone respectively, remove unreacted monomers and initiators, and then dry to obtain Graft modified products.

Embodiment 3

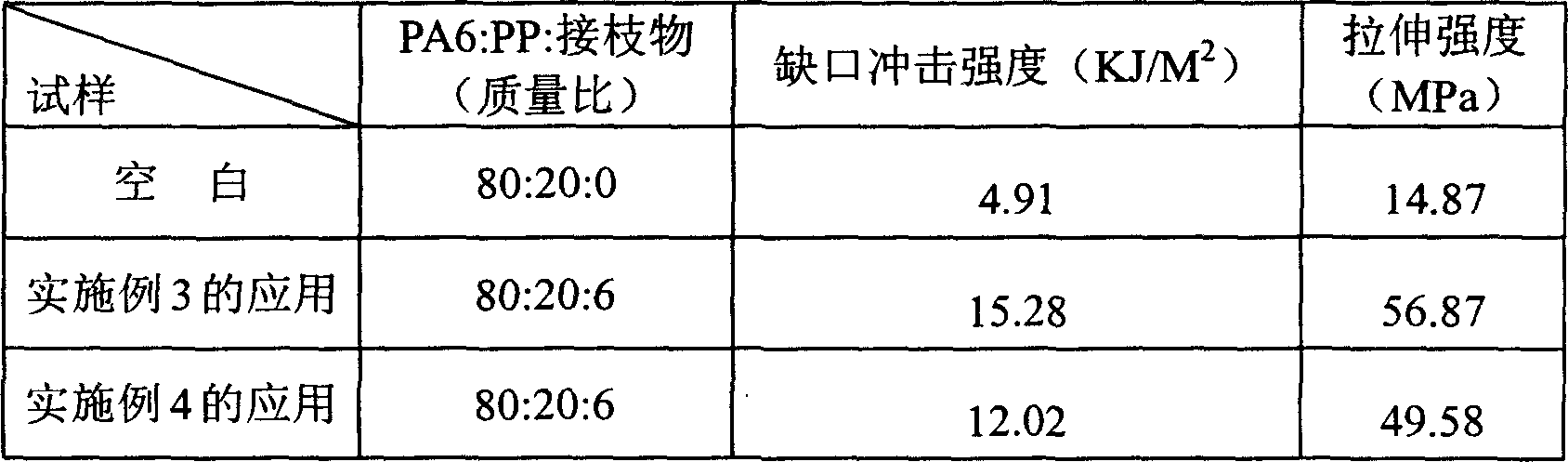

[0034] The initiator benzoyl peroxide is dissolved in acrylic acid and methyl acrylate monomer (mass ratio is 1:1) according to 1.5% of the monomer mass, and then the porous polypropylene (PP) particles with a porosity of 0.14-0.44 Soak in the above monomer / initiator solution for 30 minutes to fully absorb the monomer and initiator into the pores of PP particles. Prepare brine with a concentration of 25% sodium chloride, place it in the reactor, and turn on the stirring and heating device. When the temperature reaches 85°C, put PP particles soaked in monomers and initiators, react for 3 hours, discharge, wash with distilled water and acetone respectively, remove unreacted monomers and initiators, and then dry to obtain Graft modified products. The grafted product was injected into a specimen, and the notched impact strength (kJ / M 2 ) is 5.44, the tensile strength (Mpa) is 37.54, and the yield stress (Mpa) is 31.99.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com