Composite microporous film, and production method and use thereof

一种微多孔膜、多孔质体的技术,应用在复合微多孔膜及其制造领域,能够解决易剥离等问题,达到电池反应稳定、透过性优异、机械强度优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

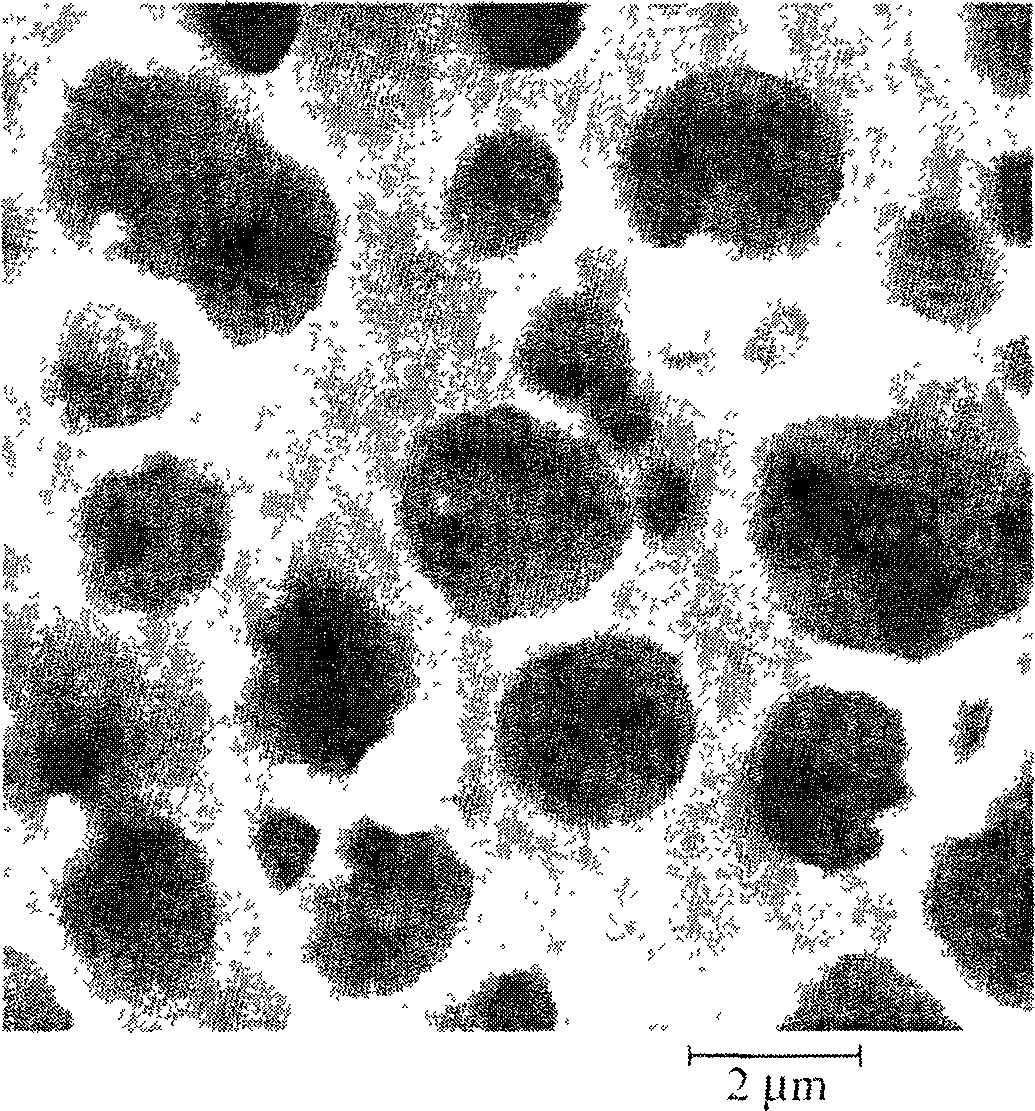

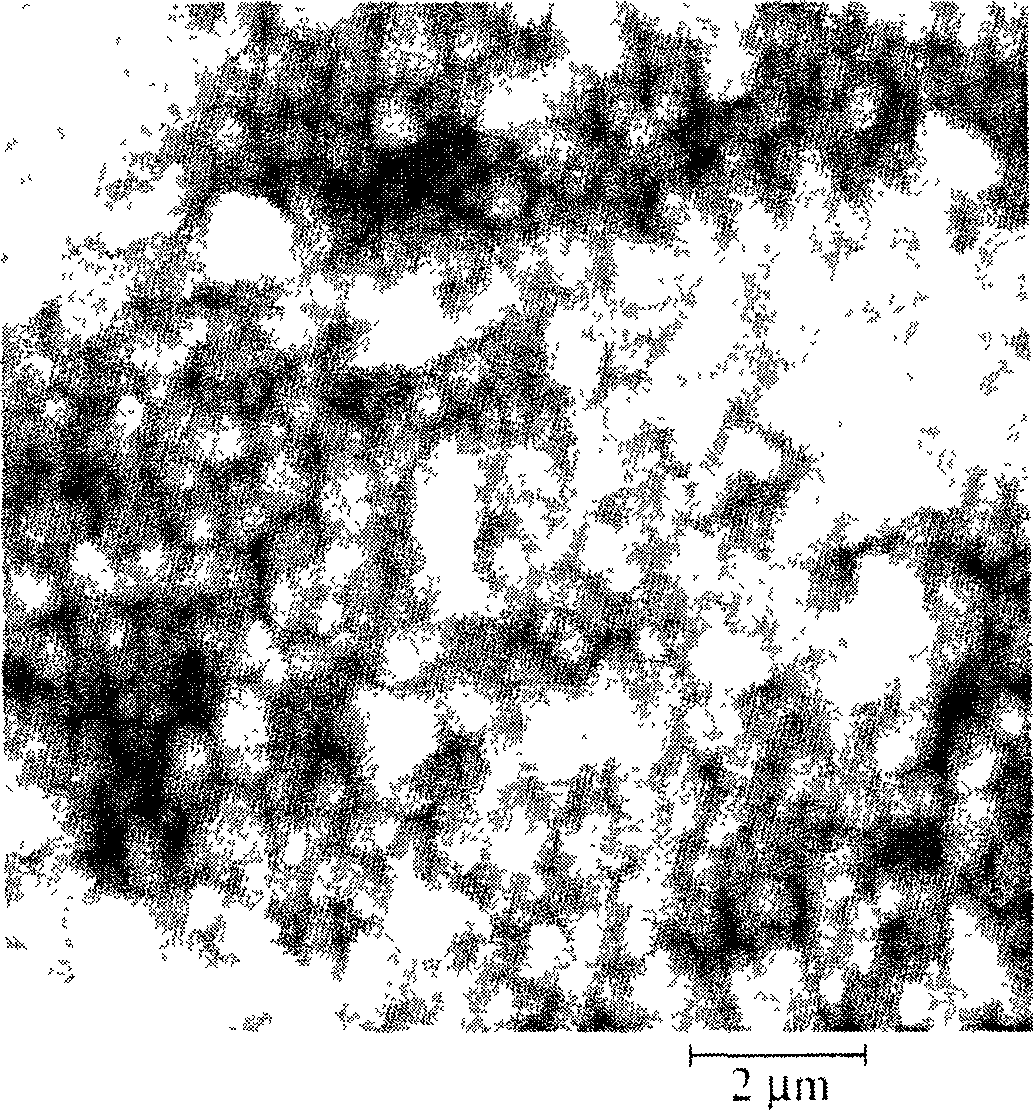

Image

Examples

Embodiment 1

[0097] (1) Preparation of fluororesin mixture

[0098] At room temperature, 2.7 parts by mass of poly(hexafluoropropylene-vinylidene fluoride) copolymer (trade name: Kynar2801, manufactured by ATOFINA Corporation, hexafluoropropylene content: about 10 mass%, melt viscosity: 2300 to 2700Pa·s) It was dissolved in 73 parts by mass of acetone to prepare a fluororesin solution. Add 24.3 parts by mass of mixed xylene to the obtained fluororesin solution (75.7 parts by mass) mol% or more than 80 mol%], the preparation of fluororesin mixture.

[0099] (2) Formation of covering layer

[0100] Polyethylene microporous film [trade name: Seti Ichira, manufactured by Tonen Chemical Co., Ltd., thickness 21.9 μm, air permeability: 253sec / 100cc, puncture strength: 3028mN / 20μm, thermal shrinkage is conveyed at a speed of 2 m / min. Efficiency: 16% (MD: 105°C / 8 hours), 5.5% (TD: 105°C / 8 hours), tensile strength at break: 90MPa (MD), 65MPa (TD), average through-hole diameter: 0.04μm, maximum po...

Embodiment 2

[0102] A composite microporous membrane was produced in the same manner as in Example 1, except that toluene (dipole moment: 0.375 Debye) was used as a poor solvent to prepare a fluororesin mixture.

Embodiment 3

[0104] Except that the mixing ratio of acetone is set to 68.1 parts by mass, and 29.2 parts by mass of 1-butanol (dipole moment: 1.68 Debye) is added as a poor solvent to prepare the fluororesin mixture, the composite microparticles are produced in the same manner as in Example 1. porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com