Method and device for solid alkylation reaction

A technology of an alkylation reaction and regeneration device, which is applied in the petrochemical field and can solve the problems that the reaction and regeneration process cannot be carried out continuously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

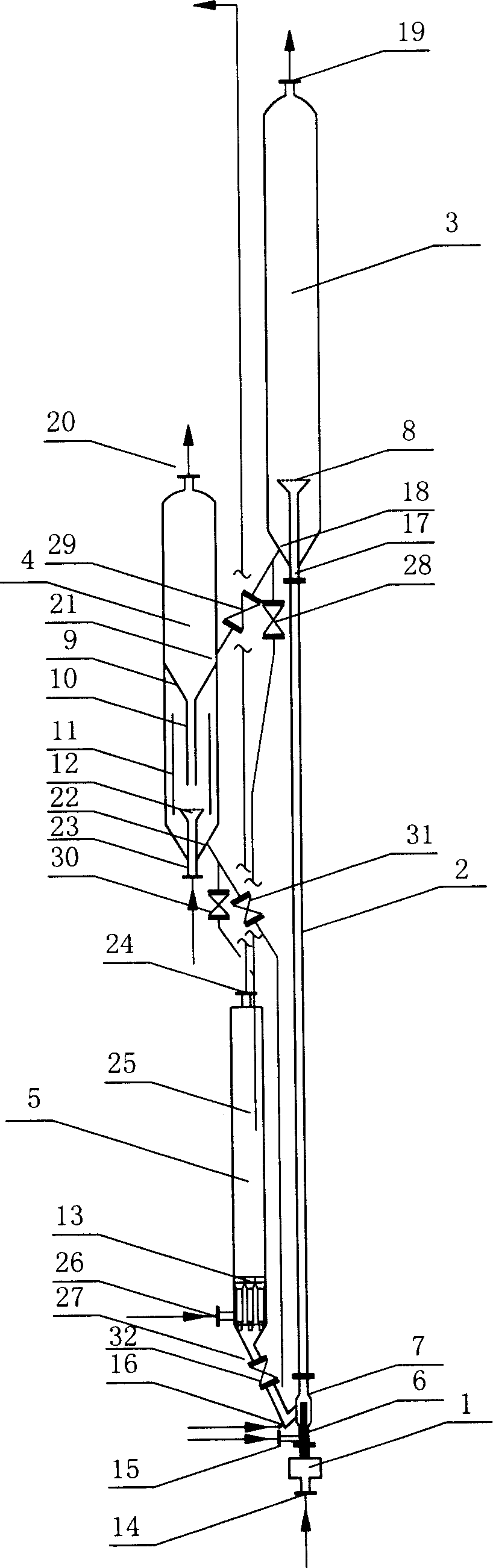

[0047] see Figure 8 , the solid acid alkylation reaction regeneration method of this embodiment mainly utilizes the circuit formed by the liquid distributor 1, the riser reactor 2, the fluidized bed reactor 3 and the circulation bed regenerator 4, by opening Figure 8 Middle control valve 29 and control valve 31, close control valve 28, control valve 30 and control valve 32 (see figure 1 ) device of the present invention can be set to this circuit operation. The specific process is that the reaction liquid mixed according to the reaction ratio is divided into two paths and pumped into the liquid distributor 1 by the metering pump from the primary reaction liquid inlet 14 and the secondary reaction liquid inlet 15 respectively, and the reaction liquid flow entered by the primary reaction liquid inlet The catalyst particles are in the circulating bed state, and the reaction liquid flow entering from the secondary reaction liquid inlet is used to change the resistance at the ca...

Embodiment 2

[0050] see Figure 9 , the regeneration method of solid acid alkylation reaction in this embodiment mainly utilizes the circuit composed of liquid distributor 1, riser reactor 2, fluidized bed reactor 3 and moving bed regenerator 5, by opening Figure 9 Control valve 28 and control valve 32 in, close control valve 29, control valve 30 and control valve 31 (see figure 1 ) device of the present invention can be set to this circuit operation. In the specific process, the part where the catalyst particles are subjected to the alkylation reaction in the riser reactor 2 and the fluidized bed reactor 3 is the same as that in the first embodiment. The difference is that after the catalyst particles flow out from the outlet 18 at the bottom of the fluidized bed, they enter the catalyst bed in the moving bed regenerator 5 through the control valve 28 through the connecting pipeline. It should be noted that the length of the catalyst particle inlet line 25 inserted into the moving bed ...

Embodiment 3

[0052] see Figure 10 , The solid acid alkylation reaction regeneration method in this embodiment mainly utilizes a circuit composed of a liquid distributor 1 , a riser reactor 2 , a fluidized bed reactor 3 , a circulating bed regenerator 4 and a moving bed regenerator 5 . by opening Figure 10 Control valve 29, control valve 30 and control valve 32 in the middle, close control valve 28 and control valve 31 (see figure 1 ) device of the present invention can be set to this circuit operation. In the specific process, the reaction part of the alkylation reaction of the catalyst particles in the riser reactor 2 and the fluidized bed reactor 3 is the same as that in the first embodiment. During the regeneration process, the unused catalyst particles at the bottom of the fluidized bed reactor 3 leave from the outlet 18 at the bottom of the fluidized bed, and enter the circulating bed regenerator 4 from the inlet 21 in the middle of the circulating bed regenerator 4 through the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com