Double pipe electrically-controlled trailer brake valve

An electromagnetic control valve, dual-pipe technology, applied in the direction of control valve and air release valve, brake, brake components, etc., can solve the problem of inability to meet the braking force of long-wheelbase vehicles, poor braking effect, impact on the main vehicle, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

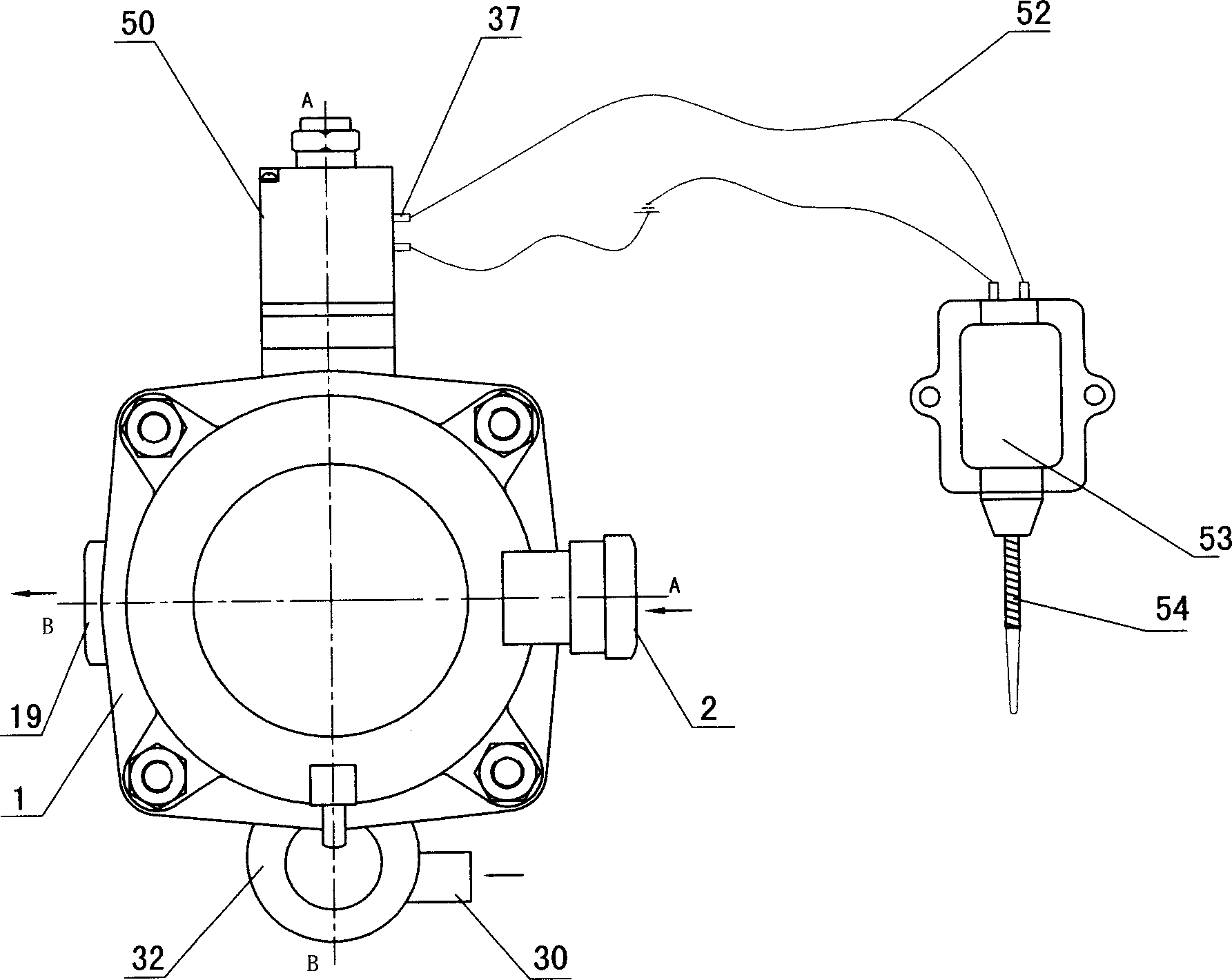

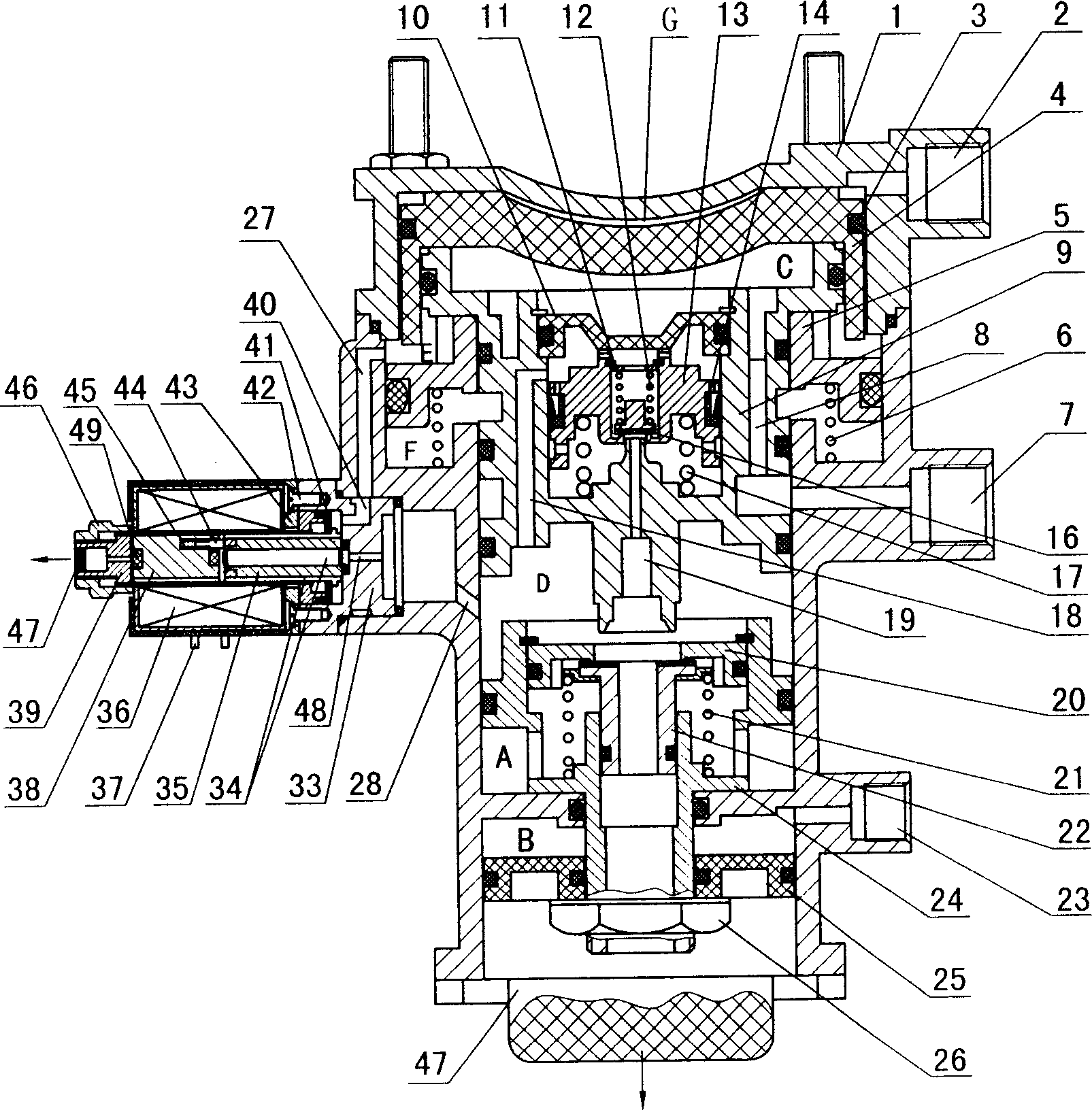

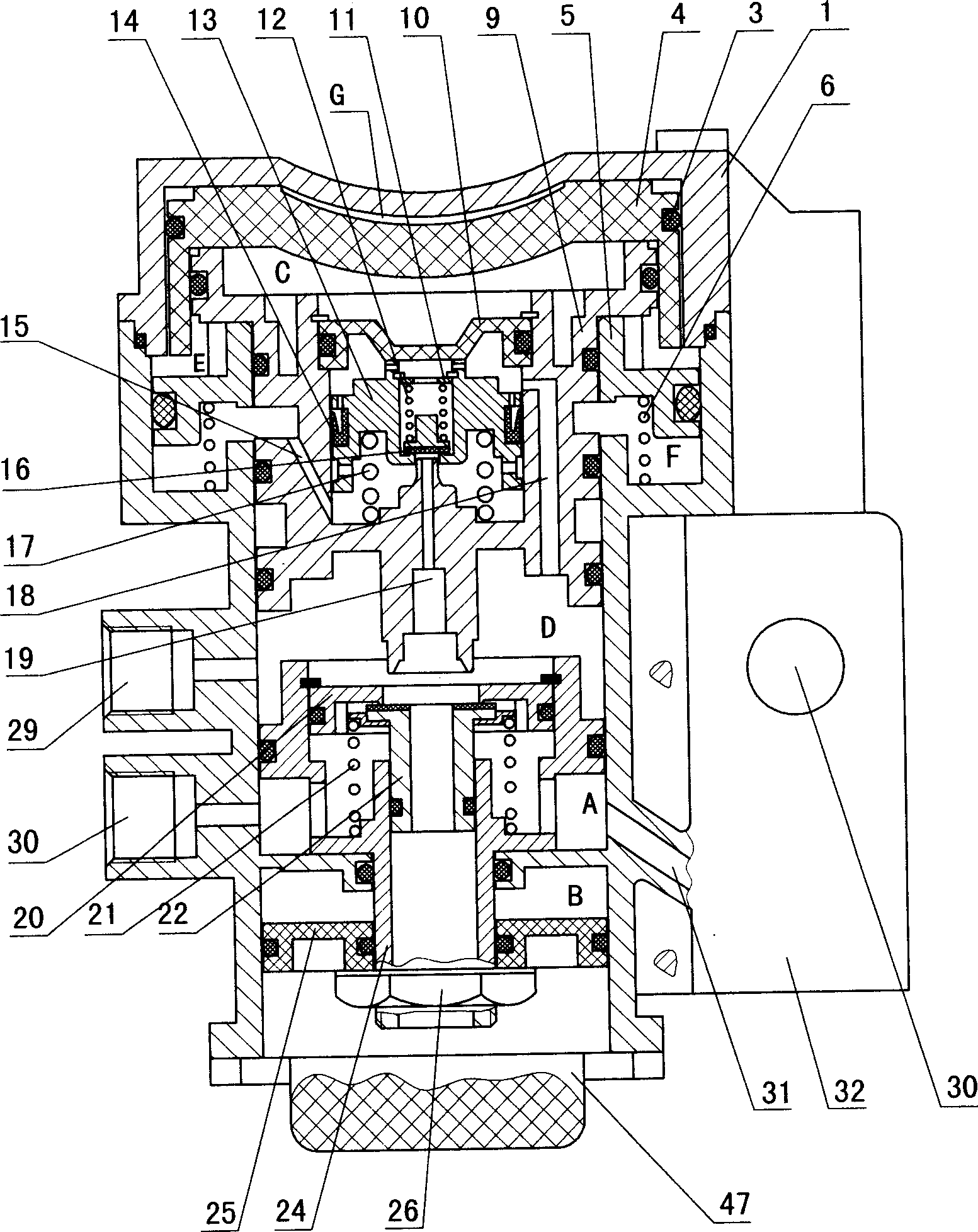

[0025] 1. Valve body 2, air inlet 3, sealing ring 4, upper relay piston 5, spacer 6, return spring 7, air inlet 8, air inlet 9, lower relay piston 10, piston seat 11, Spring seat 12, valve spring 13, air pressure adjustment piston 14, Y-shaped cup 15, air channel 16, valve 17, pressure regulating spring 18, air channel 19, exhaust channel 20, valve seat 21, valve spring 22, inlet and outlet Gas valve 23, control port 24, emergency piston 25, control piston 26, nuts 27, 28 air passage 29, air outlet 30, air inlet 31, air inlet 32, throttle valve 33, solenoid valve seat 34, air passage 35. Fixed spool 36, coil 37, terminal 38, moving spool 39, valve stem 40, air outlet 41, pressure plate 42, screw 43, positioning seat 44, push rod 45, spring 46, fixed seat 47, sound-proof Dust cover 48, air inlet 49, sealing surface 50, electromagnetic control valve 51, spring 52, electric wire 53, load sensor 54, sensing element

[0026] exist Figure 1-3 In the shown embodiment 1: the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com