Technique for cracking integral scrap tires

A waste tire and process technology, used in the petroleum industry, the preparation of liquid hydrocarbon mixtures, fibrous fillers, etc., can solve the problems of harsh operating environment, unsafe hidden dangers, and many processing links, so as to shorten the production process and eliminate unsafe hidden dangers and the effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

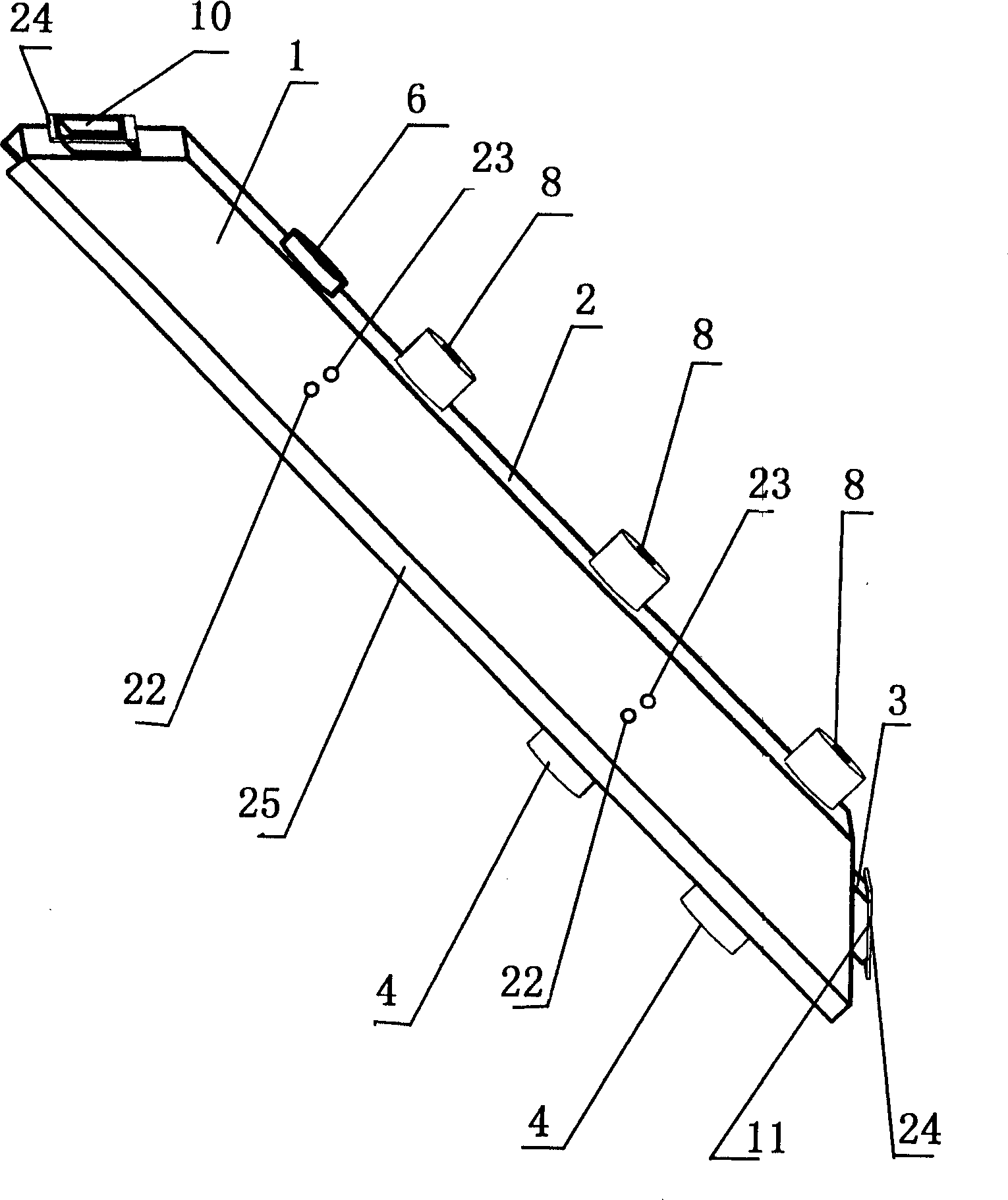

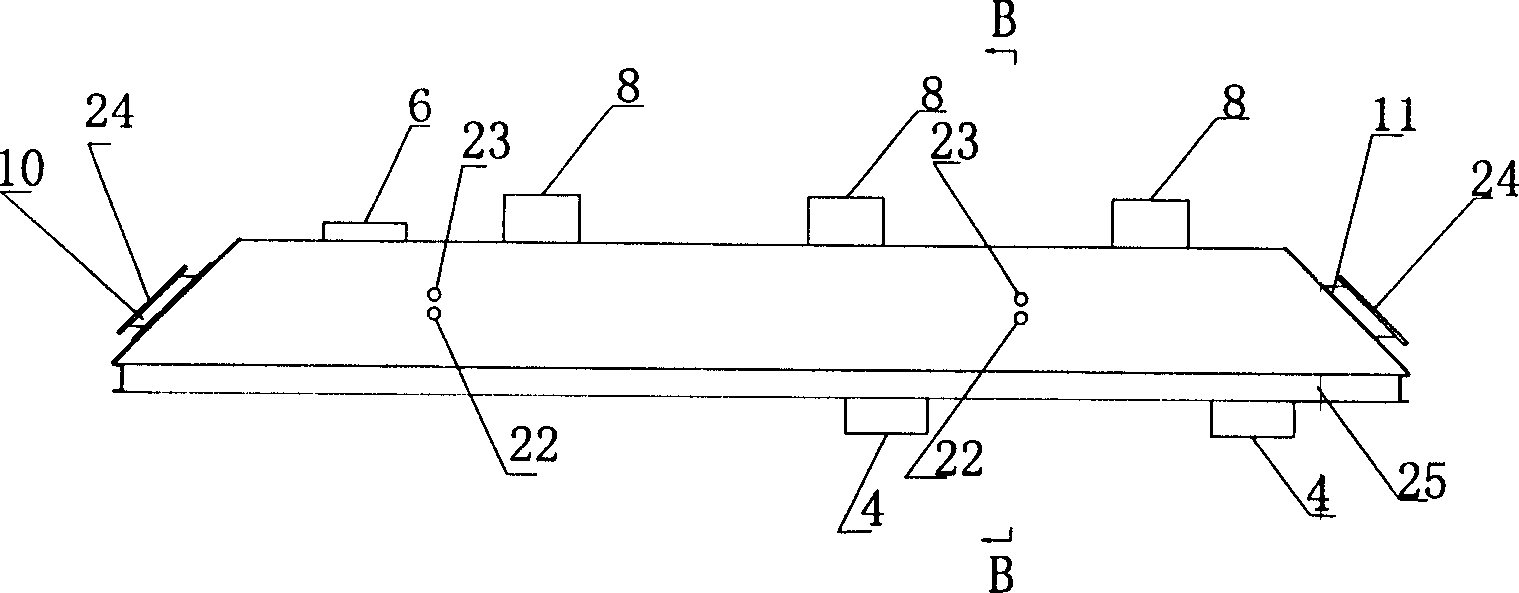

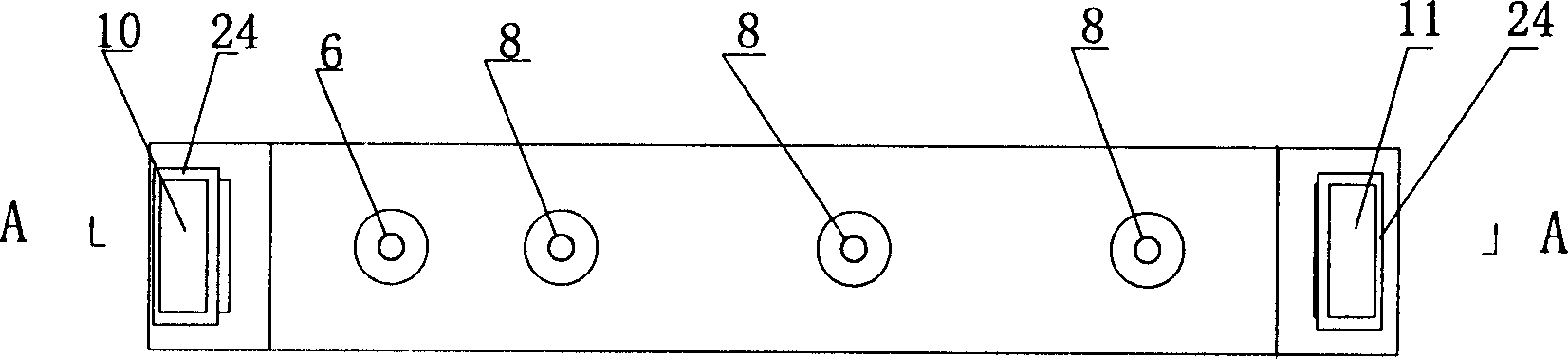

[0028] see Figure 1-Figure 7 200 kg of whole waste tires that do not need to be crushed or cut and only cleaned and descaled are sent to the feed port 10 through the conveyor belt 32, the discharge furnace door 36 is closed, the feed furnace door 17 is opened, and the waste tires are put into the waste tires in sequence. In the liner 3, since the kettle body and the ground maintain a 30-50° inclination angle 9, the waste tires will slide down freely in the liner 3 relying on gravity, and continuous feeding can make the waste tires arranged in the inner tube 3 until Full of, close charging furnace door 17. Open hot-blast stove 31, provide the hot air flow that temperature is 600-800 ℃, enter heating layer 5 from the hot air inlet 4 of cracking kettle 1 and circulate and heat liner 3, be provided with shunt channel 15 in heating layer 5, heat layer The inner tank 5 is divided into multiple passages to increase the heat transfer rate so that the temperature of the inner tank 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com