Large-area steel plate defect flux-leakage detection method

A magnetic flux leakage detection, large-area technology, applied in the direction of material magnetic variables, can solve the problems of low detection efficiency, low detection accuracy, large driving force, etc., to improve the coverage and spatial resolution, ensure detection accuracy, magnetic The effect of road parameter optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

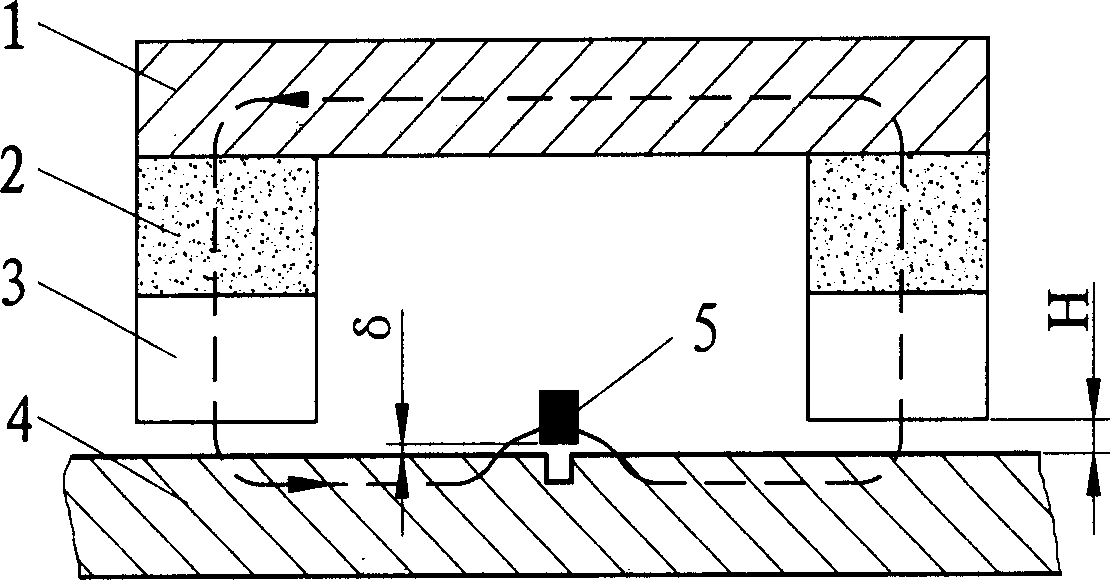

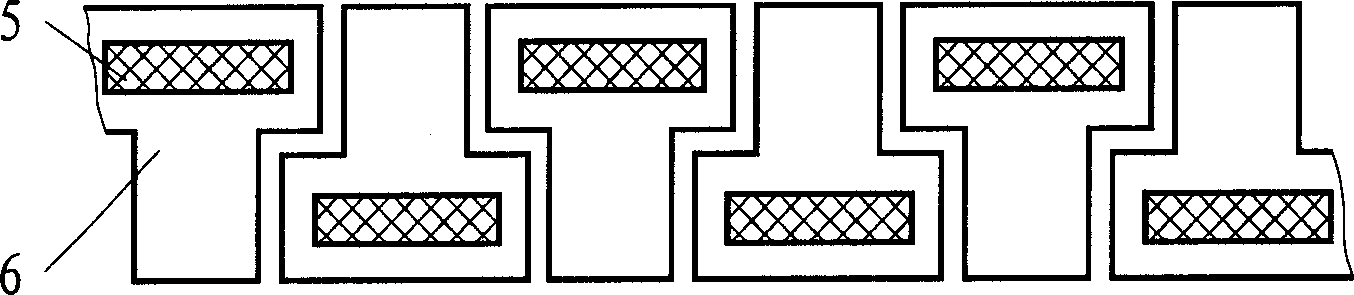

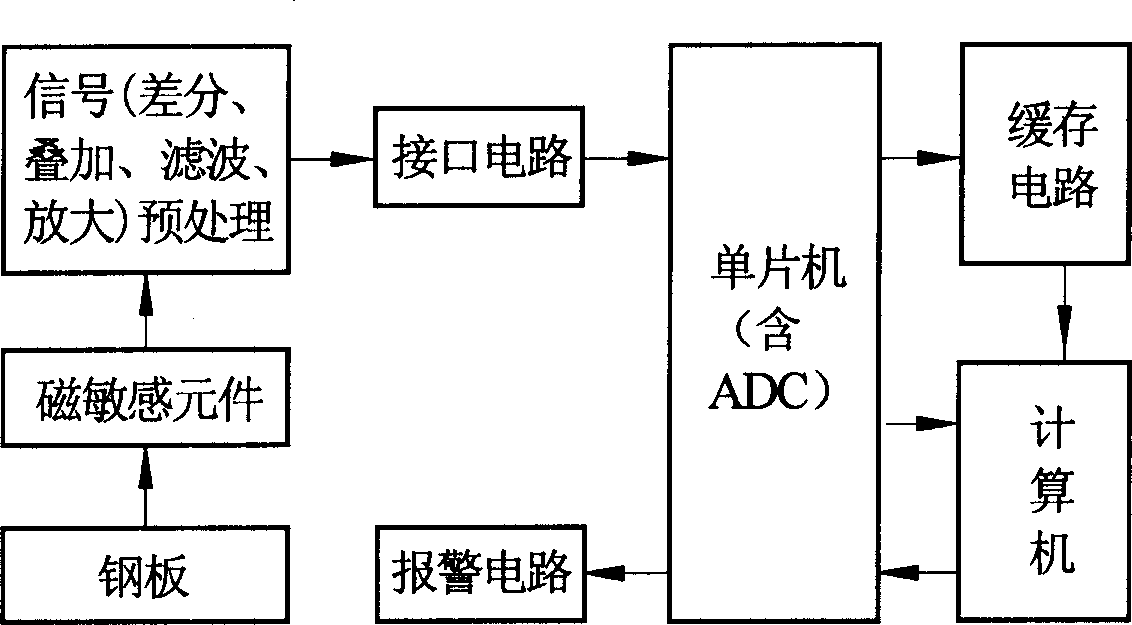

[0022] Select the 12mm thick Q235 steel plate as the object to be detected, and select the NdFeB N50 rare earth permanent magnet material with a length of 300mm, a width of 30mm, and a thickness of 25mm to form the excitation device according to the saturation magnetic flux density of the Q235 material and the calculation of formula (1). =5mm magnetization air gap to magnetize the steel plate to make it to local magnetization saturation; according to the attached figure 2 Explain that 36 integrated Hall elements are dislocated and arranged to form a detection probe, and the interval between the magnetically sensitive areas of adjacent elements is 2mm; the probe is used to measure the magnetization direction with a lift-off value of 2.5mm and a sampling interval of 2mm. The magnitude of the magnetic field at different positions on the steel plate surface; firstly, the output signals of every two adjacent magnetic sensitive elements are differentially processed, and then the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com