Composite phosphate grease-adding agent for leather and its preparation method

A compound phosphate ester and leather fatliquor technology, applied in leather impregnation, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve long production cycle , high production equipment requirements, single performance and other issues, to achieve good low-temperature storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

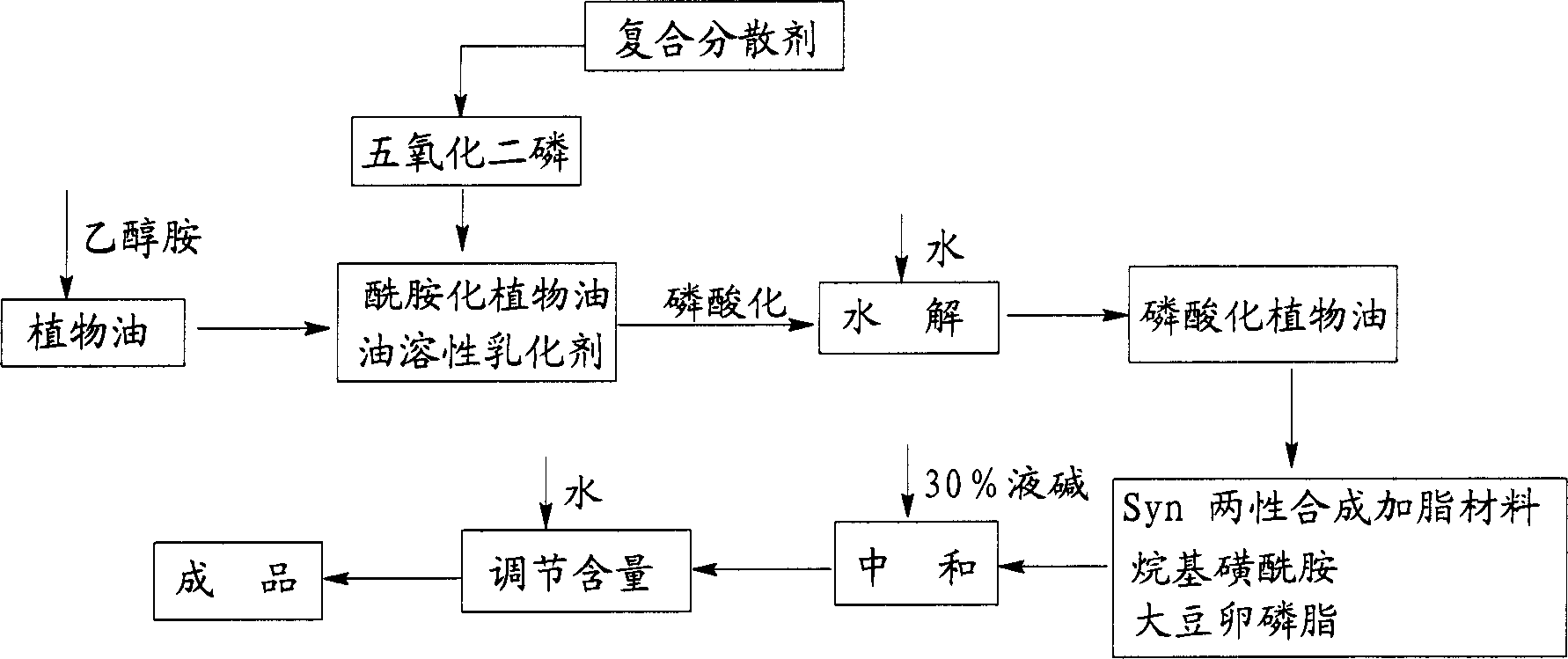

Method used

Image

Examples

Embodiment 1

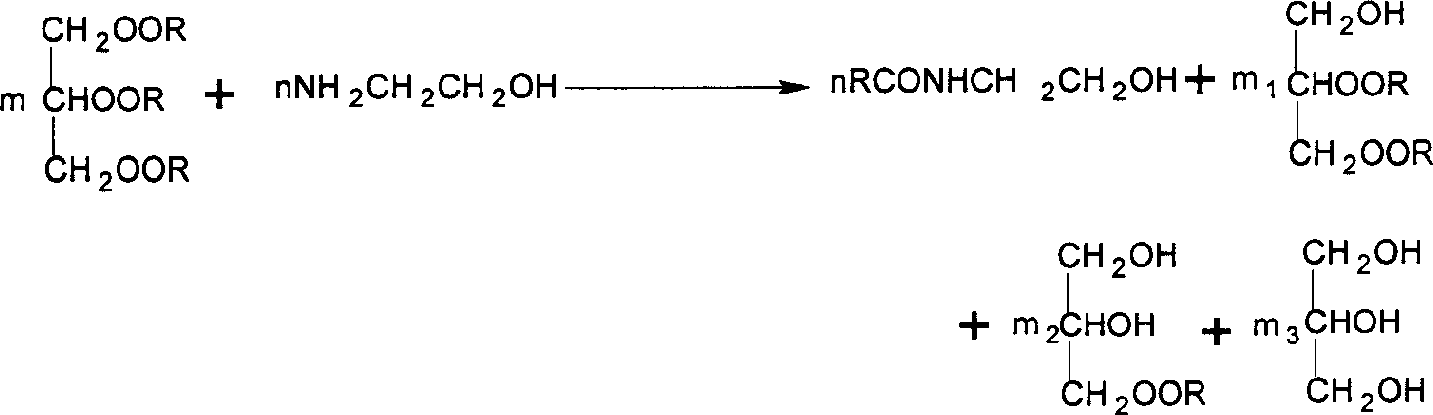

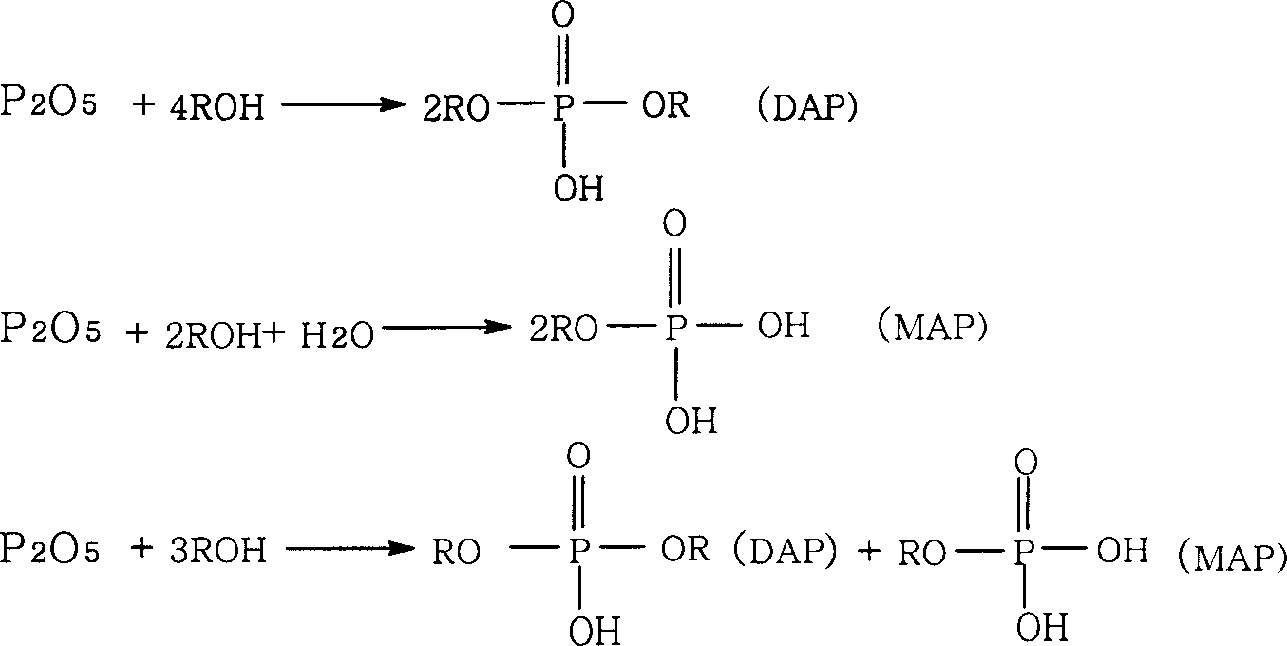

[0043] Add 100.0g rapeseed oil and 7.0g monoethanolamine into a dry four-necked glass flask equipped with a stirrer and a condenser, and heat up to 135°C for amidation reaction. After the reaction is carried out for 2.5 hours, a hydroxyl value of 113.94mgKOH / g is obtained. Amidated rapeseed oil. Add 3.21g (3% by weight of the amidated rapeseed oil) Span80 to the amidated rapeseed oil. At this time, the total amount of hydroxyl substances in the system is 0.2292mol, and then slowly add 21.87g composite dispersant (m[containing Chlorinated rape oil fatty acid methyl ester with a chlorine content of 20%]: m[No. 5 white oil] = 2.5:1) 14.58g of P dissolved 2 O 5 (OH:P 2 O 5 [mol]=1:0.45) Phosphorylation, keeping the reaction temperature at 75°C for 2.0 h. Then add 2.78g water (H 2 O: P 2 O 5 [mol]=1.5:1) Hydrolyze to obtain phosphorylated rapeseed oil. Then the system was cooled to 55°C, 59.77g leather-specific alkyl sulfonamide, 59.77g Syn amphoteric synthetic fatliquor material and 2...

Embodiment 2

[0045] Add 100.0g palm oil and 8.0g monoethanolamine into a dry four-necked glass flask equipped with a stirrer and a condenser, and heat to 140°C for amidation reaction. After the reaction is carried out for 2.5 hours, an amide with a hydroxyl value of 129.01mgKOH / g is obtained. Palm oil. Add 4.32g (4% of the weight of amidated palm oil) Span80 to the amidated palm oil. At this time, the total amount of hydroxyl substances in the system is 0.2647mol, and then slowly add 26.94g of composite dispersant (m[chlorine content 20% chlorinated rape oil fatty acid methyl ester]: m[No. 5 white oil] = 2.5:1) 16.84g of P dissolved 2 O 5 (OH:P 2 O 5 [mol]=1:0.45) Phosphorylation, keeping the reaction temperature at 75°C for 2.0 h. Then add 3.43g water (H 2 O: P 2 O 5 [mol]=1.5:1) Hydrolyze to obtain phosphorylated palm oil. Then the system was cooled to 60°C, 63.81g leather-specific alkyl sulfonamide, 63.81g Syn amphoteric synthetic fatliquor material and 31.90g soybean lecithin were added to...

Embodiment 3

[0047] Add 100.0g rapeseed oil and 9.0g monoethanolamine into a dry four-necked glass flask equipped with a stirrer and a condenser, and heat to 140°C for amidation reaction. After the reaction is carried out for 2.5 hours, a hydroxyl value of 143.81mgKOH / g is obtained. Amidated rapeseed oil. Add 4.36g (4% of the weight of the amidated rapeseed oil) Span80 to the amidated rapeseed oil, at this time the total amount of hydroxyl substances in the system is 0.2964mol, and then slowly add 31.52g composite dispersant (m[containing Chlorinated rape oil fatty acid methyl ester with a chlorine content of 20%]: m[No. 10 white oil]=2.5:1) dissolved 19.70g of P 2 O 5 (OH:P 2 O 5 [mol]=1:0.47) Phosphorylation, keeping the reaction temperature at 80°C for 2.0 h. Then add 4.51g water (H 2 O: P 2 O 5 [mol]=1.8:1) Hydrolyze to obtain phosphorylated rapeseed oil. Then the system was cooled to 55°C, 93.93g leather-specific alkyl sulfonamide, 93.93g Syn amphoteric synthetic fatliquor material and 19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com