Seatbelt retractor and seatbelt device equipped with the seatbelt retractor

A seat belt retractor and seat belt technology, which is applied to the structure of seat belts/slings, in-vehicle seat belts, belt tensioners, etc., can solve the problem that the force transmission part 13 is difficult to return, engage and disengage, and limit the load. It can not be uniform and other problems to achieve the effect of reducing the drop of seat belt load, reliable torsional deformation, and absorbing impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Preferred modes for implementing the present invention will be described below with reference to the drawings.

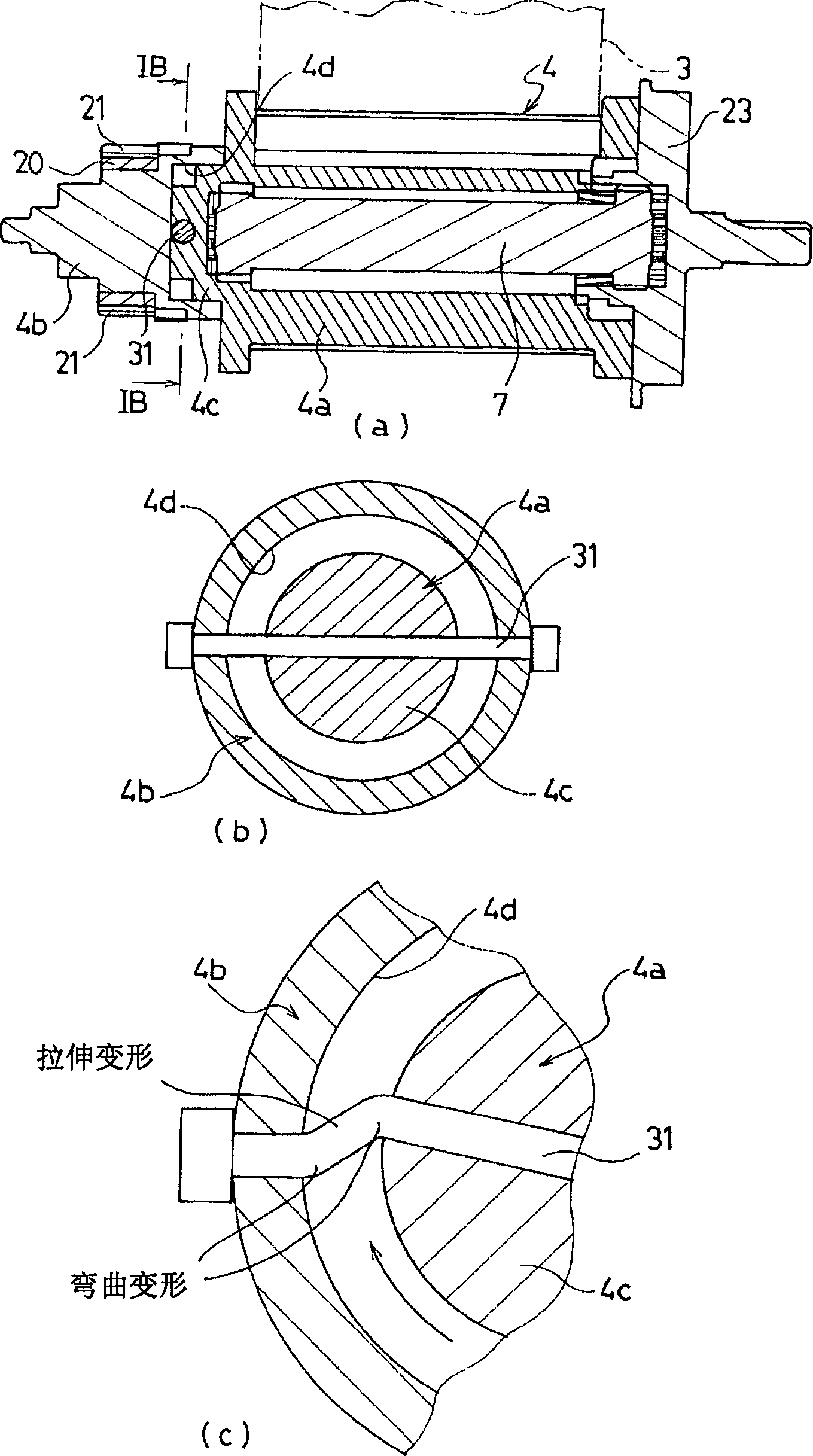

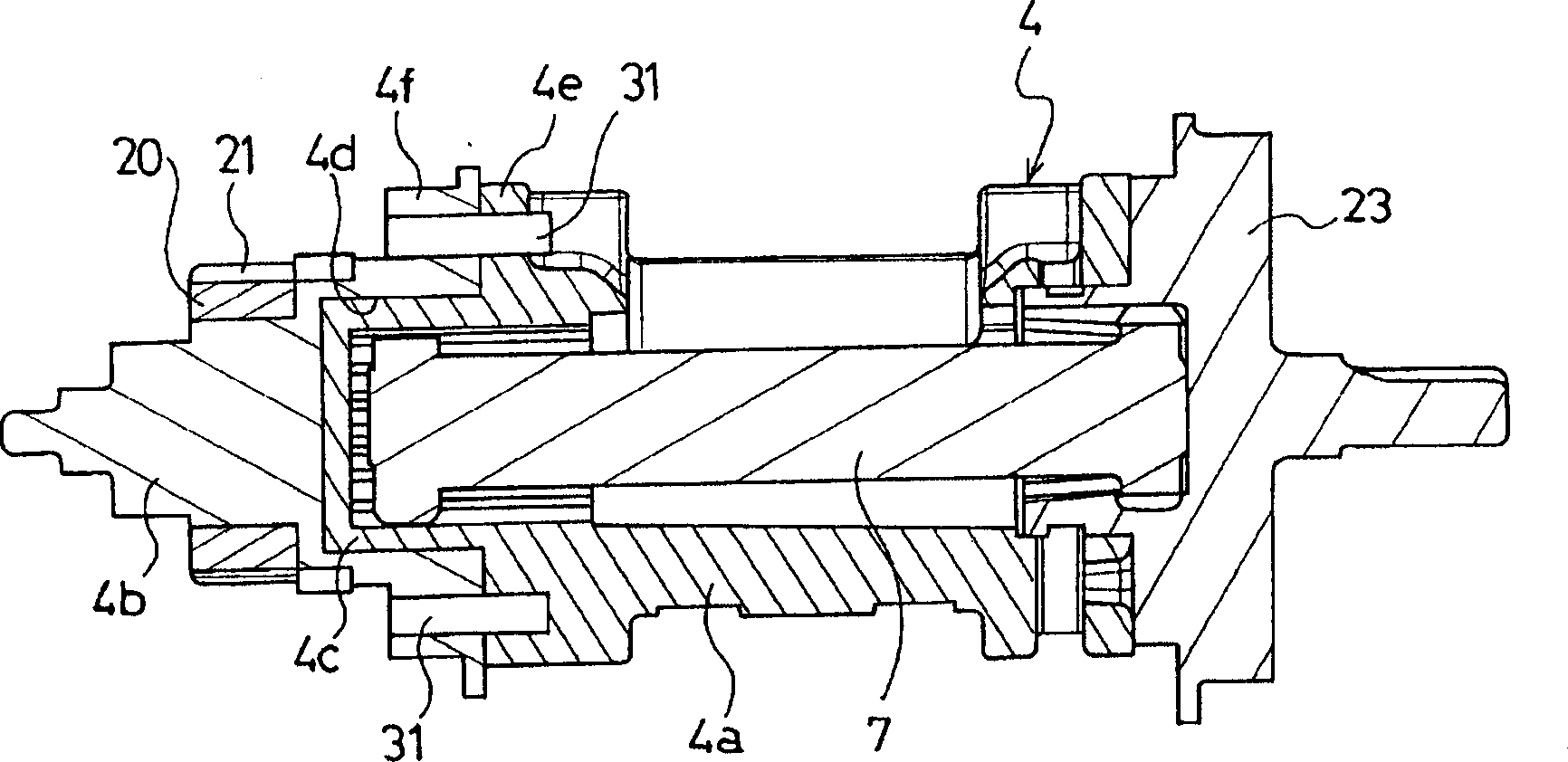

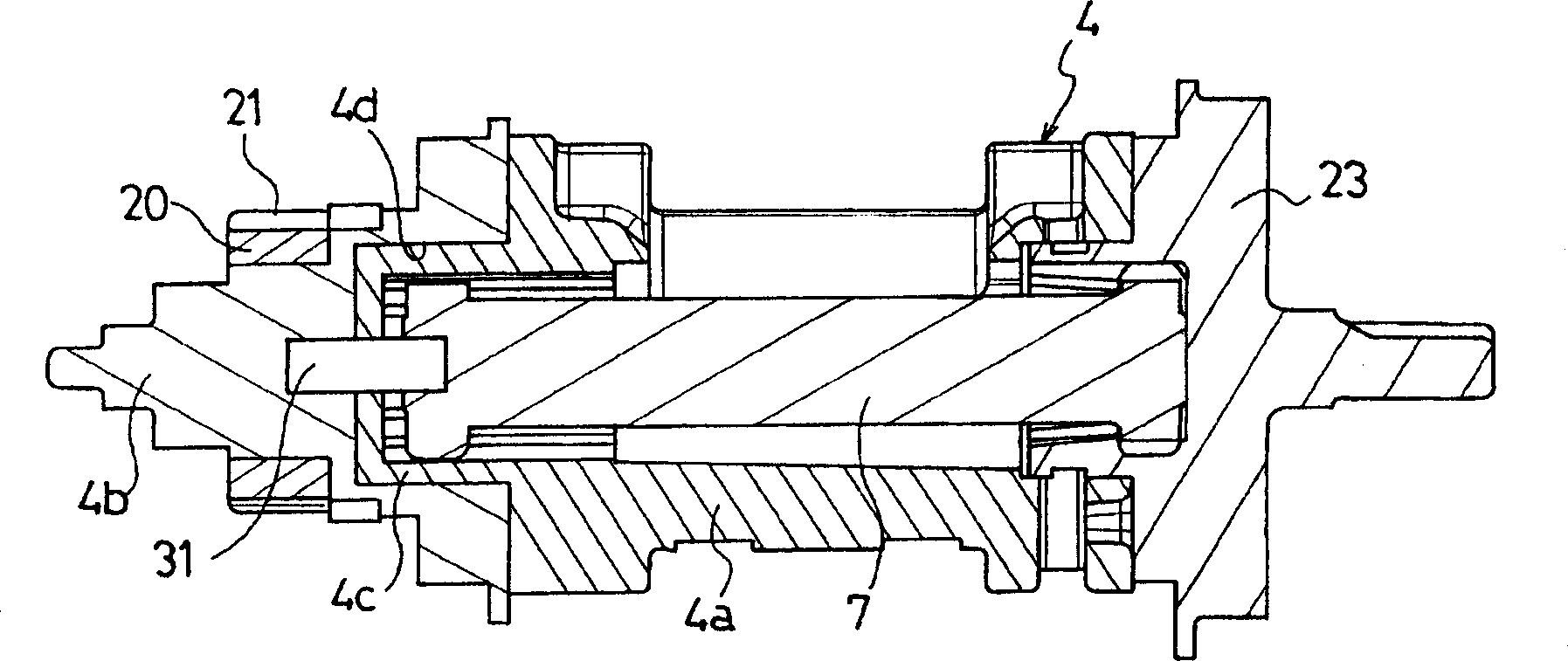

[0052] figure 1 Partially and schematically showing an example of an embodiment of the seat belt retractor according to the present invention, (a) shows a sectional view of the spool of this example, and (b) is taken along the line IB-IB in (a) (c) is a partial enlarged view for explaining the behavior of the pretensioner after operation. And in the description of each embodiment below, for the example before this example and the above Figure 10 (a), (b) and Figure 11 The same constituent elements in the shown conventional example are denoted by the same symbols, and detailed description thereof will be omitted.

[0053] in the above Figure 10 (a), (b) and Figure 11 In the shown conventional example, the spool 4 is integrally constituted by a single part with the belt winding portion of the seat belt 3 and the fixing portion of the pinion 20 of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com