Modularized liquid distributor

A liquid distributor and modular technology, applied in chemical instruments and methods, fractionation, separation methods, etc., can solve problems affecting tower efficiency, packing height reduction, technical difficulties, etc., to improve overall performance and prevent mist entrainment and wall flow, the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

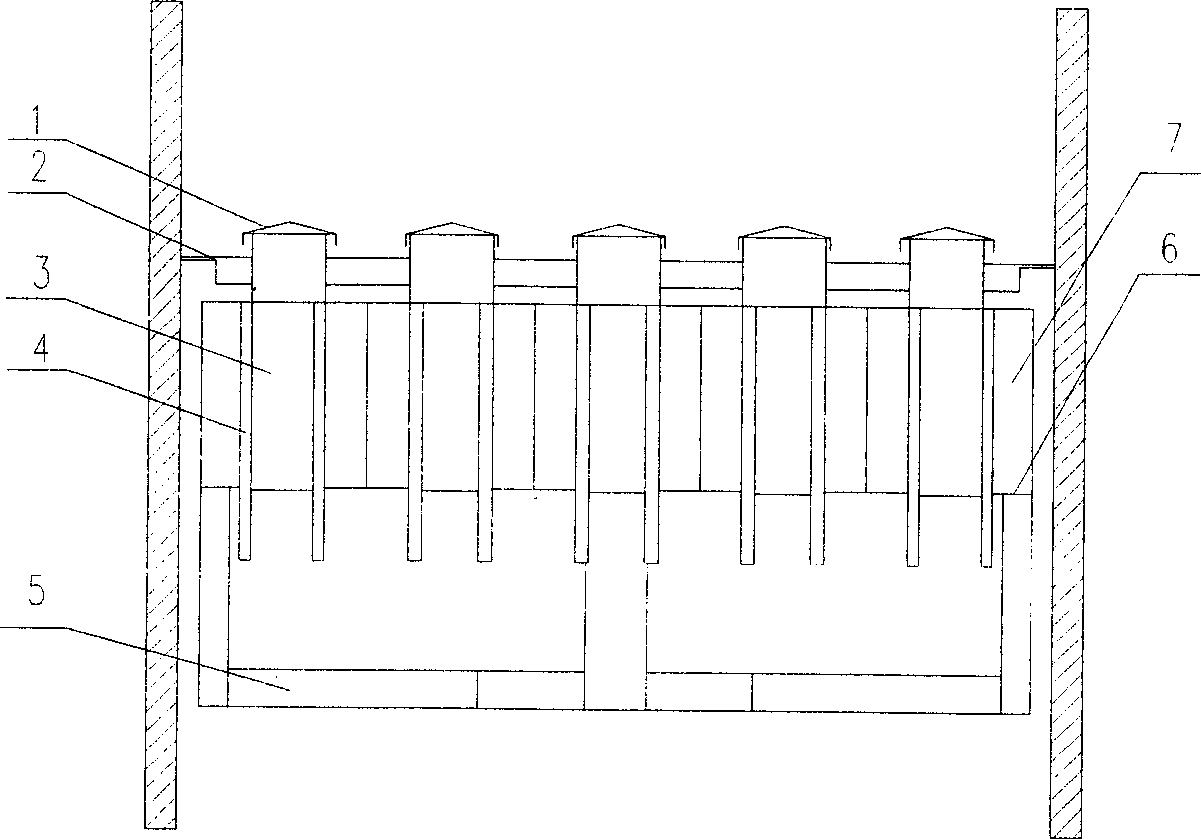

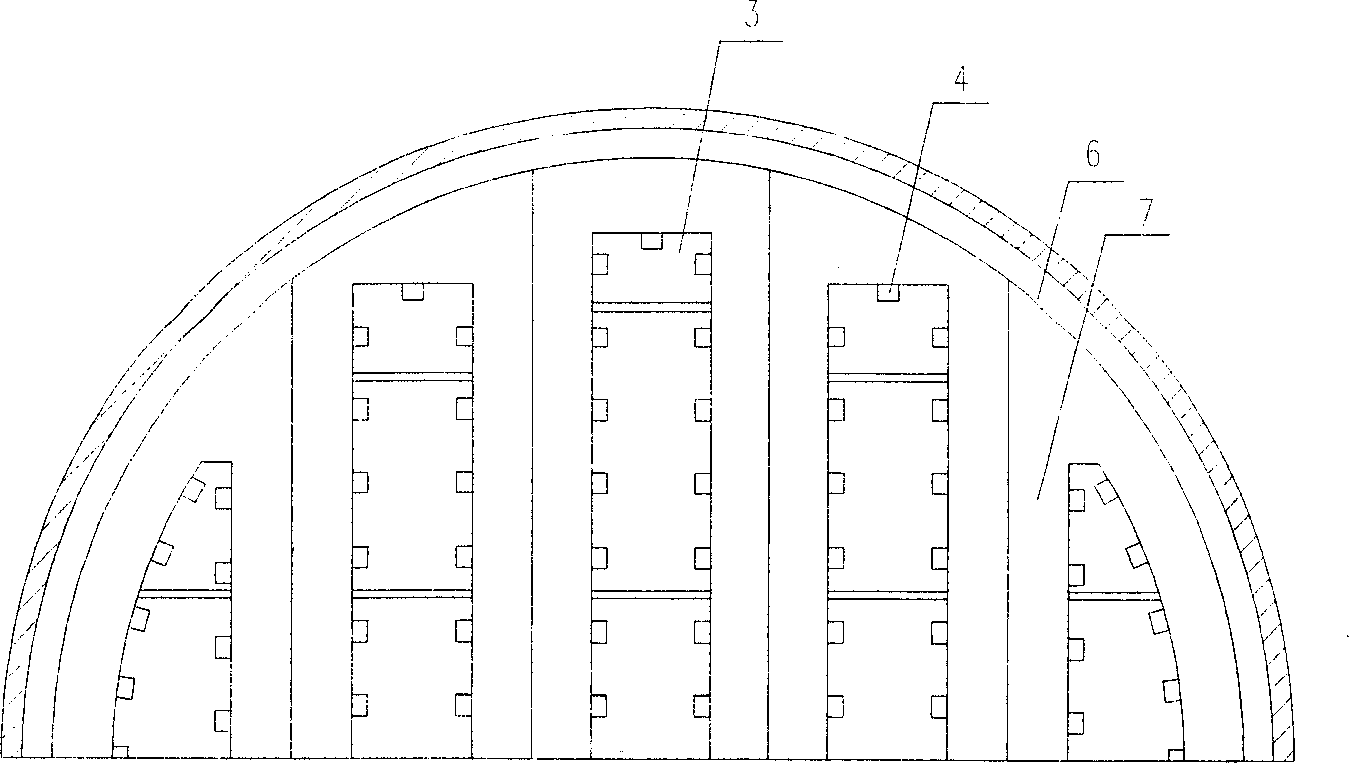

[0026] Such as figure 2 and image 3 As shown, the chassis 6 is evenly provided with a lift box 3 connected up and down, and a liquid guide tank 4 is arranged on the walls around the lift tank 3, and a spray hole is arranged on the corresponding upper end of the liquid guide tank 4, and the liquid guide tank 4 is connected with the lower edge of the liquid collecting cone 2, and guides the liquid flowing down the tower wall, and the space adjacent to the lift box forms a collecting tank 7, so as to realize the collection and redistribution of the liquid. The top of the lift box 3 is provided with a cap-type liquid baffle 1 . Described guide groove 4 is channel steel. A support beam 5 is arranged under the chassis 6 . The support beam 5 may be box-shaped or beam-shaped.

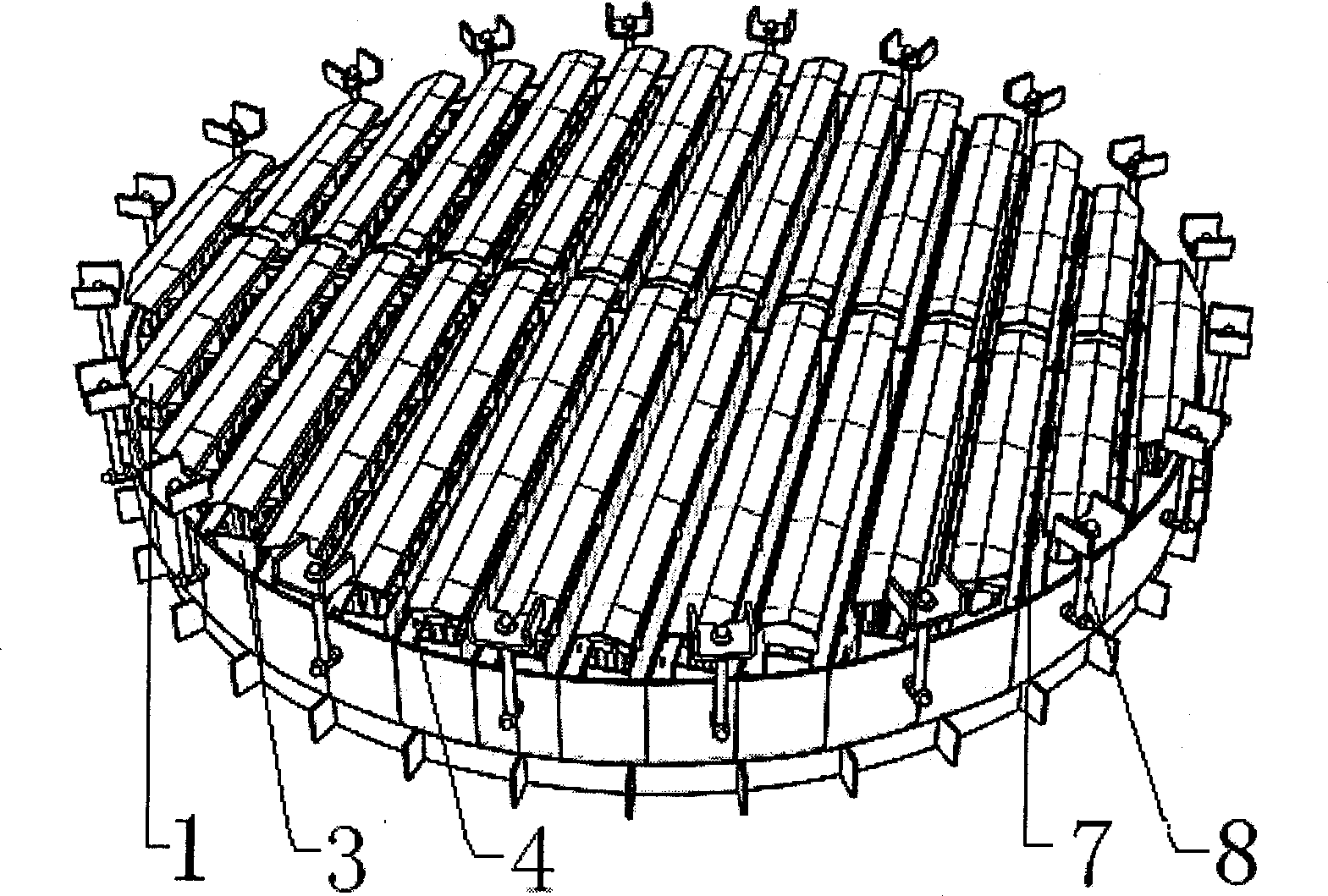

[0027] Reuse as attached Figure 4 Figure 5 In the way shown, the tie rod 8 is positioned and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com