Preparation method of composite rifampicin micro-tablet capsule

A technology of rifampicin microtablets and microtablets, which is applied in capsule delivery, medical preparations containing active ingredients, pharmaceutical formulas, etc., and can solve problems such as degradation that is difficult to overcome and quality decline of FDC preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

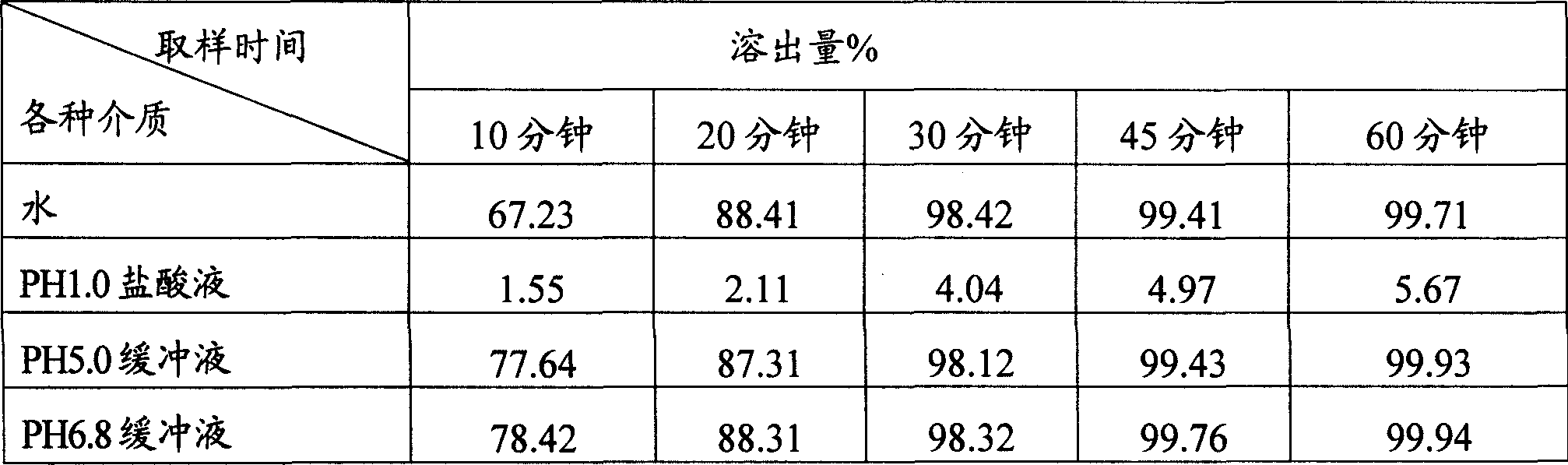

[0032] Example 1 Preparation and in vitro drug release characteristics of isoniazid enteric-coated microtablets:

[0033] 1. Preparation of isoniazid enteric-coated microtablets

[0034] Prescription of isoniazid tablets 25g of isoniazid, 5g of starch, appropriate amount of 5% povidone (K30) solution, 0.12g of magnesium stearate, 1000 tablets in total.

[0035] Preparation method Weigh isoniazid and starch respectively according to the prescription quantity, pass through a 100-mesh sieve and mix evenly, granulate with 5% povidone (K30) solution, dry in an oven at 60°C, sieve, granulate, add hard Magnesium fatty acid was mixed and pressed into tablets with a diameter of 4mm.

[0036] Preparation of enteric coating solution: take 5 g of hydroxypropylmethyl phthalate, add 100 ml of acetone / ethanol solution (3 / 7) to dissolve, add 0.5 g of diethyl phthalate, and dissolve evenly.

[0037] Preparation of enteric-coated micro-tablets: Put the prepared plain tablets in the coating pa...

Embodiment 2

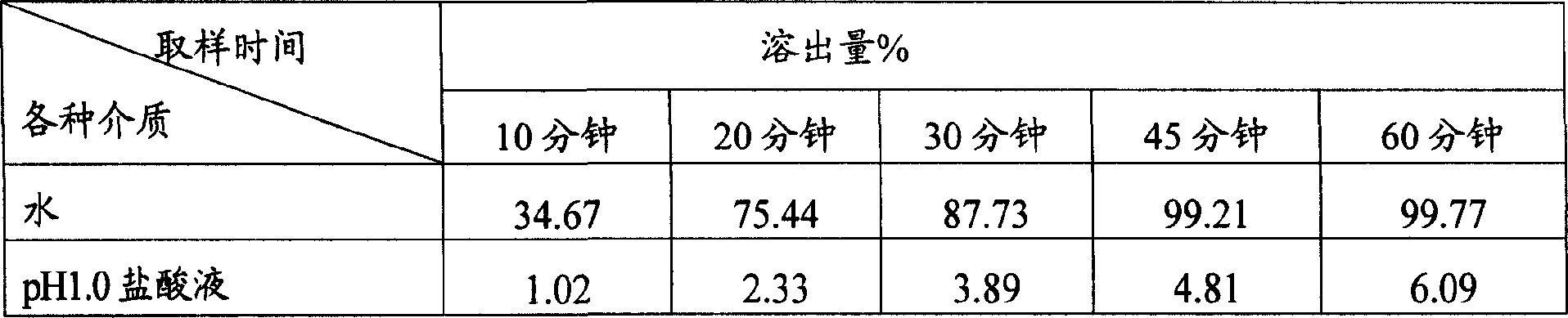

[0043] Example 2 Preparation and in vitro drug release characteristics of rifampicin enteric-coated microtablets

[0044] 1. Preparation of rifampicin enteric-coated microtablets

[0045] Rifampicin tablet prescription rifampicin 50g, microcrystalline cellulose 15g, vitamin C 1g, sodium carboxymethyl starch 1g, magnesium stearate 0.25g, a total of 1000 tablets were made.

[0046] Preparation method According to the above prescription, the raw materials and auxiliary materials are weighed, passed through an 80-mesh sieve, mixed evenly, granulated, granulated, compressed into tablets, and the diameter of the tablets is 5.5mm.

[0047] Preparation of film coating solution: take 3 g of hydroxypropyl methylcellulose and 3 g of polyethylene glycol 4000, and dissolve them evenly with 70% ethanol solution.

[0048] Preparation of film coating: Put the prepared plain tablets in the coating pot, roll the coating pot, spray the film coating solution while blowing hot air, wrap until the...

Embodiment 3

[0057] Example 3 Preparation and in vitro drug release characteristics of rifampicin gastric soluble microtablets

[0058] 1. Preparation of rifampicin gastric-soluble microtablets

[0059] Rifampicin tablet prescription rifampicin 50g, microcrystalline cellulose 15g, vitamin C 2g, low-substituted hydroxypropyl cellulose 4g, magnesium stearate 0.3g, a total of 1000 tablets were made.

[0060] Production method Weigh the raw materials and auxiliary materials according to the above prescription, pass through an 80-mesh sieve, mix them evenly, granulate, granulate, and compress into tablets. The diameter of the tablets is 5.5mm.

[0061] Preparation of gastric soluble coating solution: take 9 g of gastric soluble film coating premix, add 100 ml of 50% ethanol solution and dissolve evenly.

[0062] Preparation of stomach-soluble micro-tablets: Put the prepared plain tablets in the coating pan, roll the coating pan, spray the stomach-dissolving solution while blowing hot air, pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com