Method and apparatus for treating organic matter

A technology of organic matter and gas turbine, which is applied in the directions of gas turbine device, combustion method, oil supply device, etc., to achieve the effect of low initial investment and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be described below with reference to the accompanying drawings. In the embodiment, a treatment device for treating organic matter is installed in the sewage treatment device to treat organic matter with a high water content, such as sewage sludge and the like.

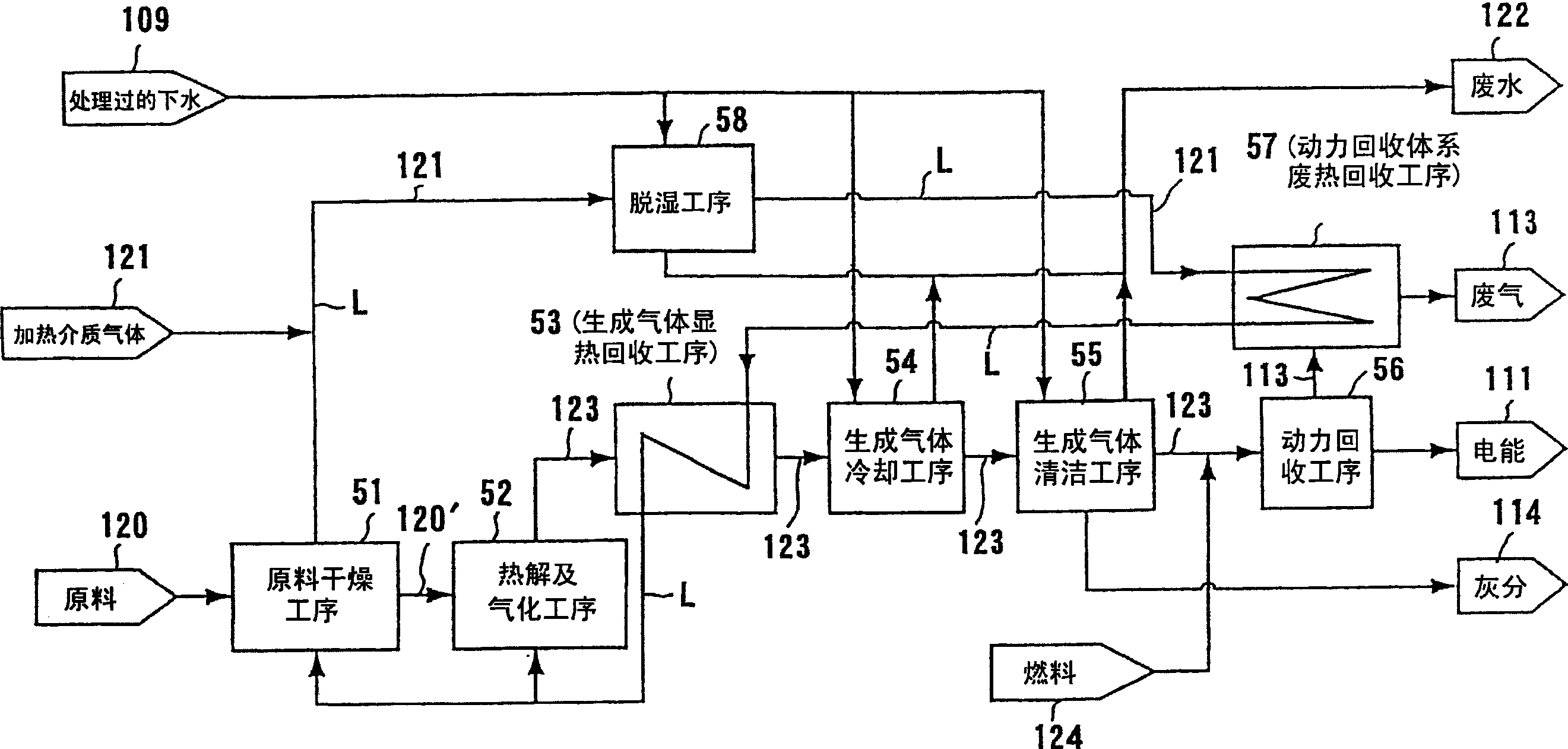

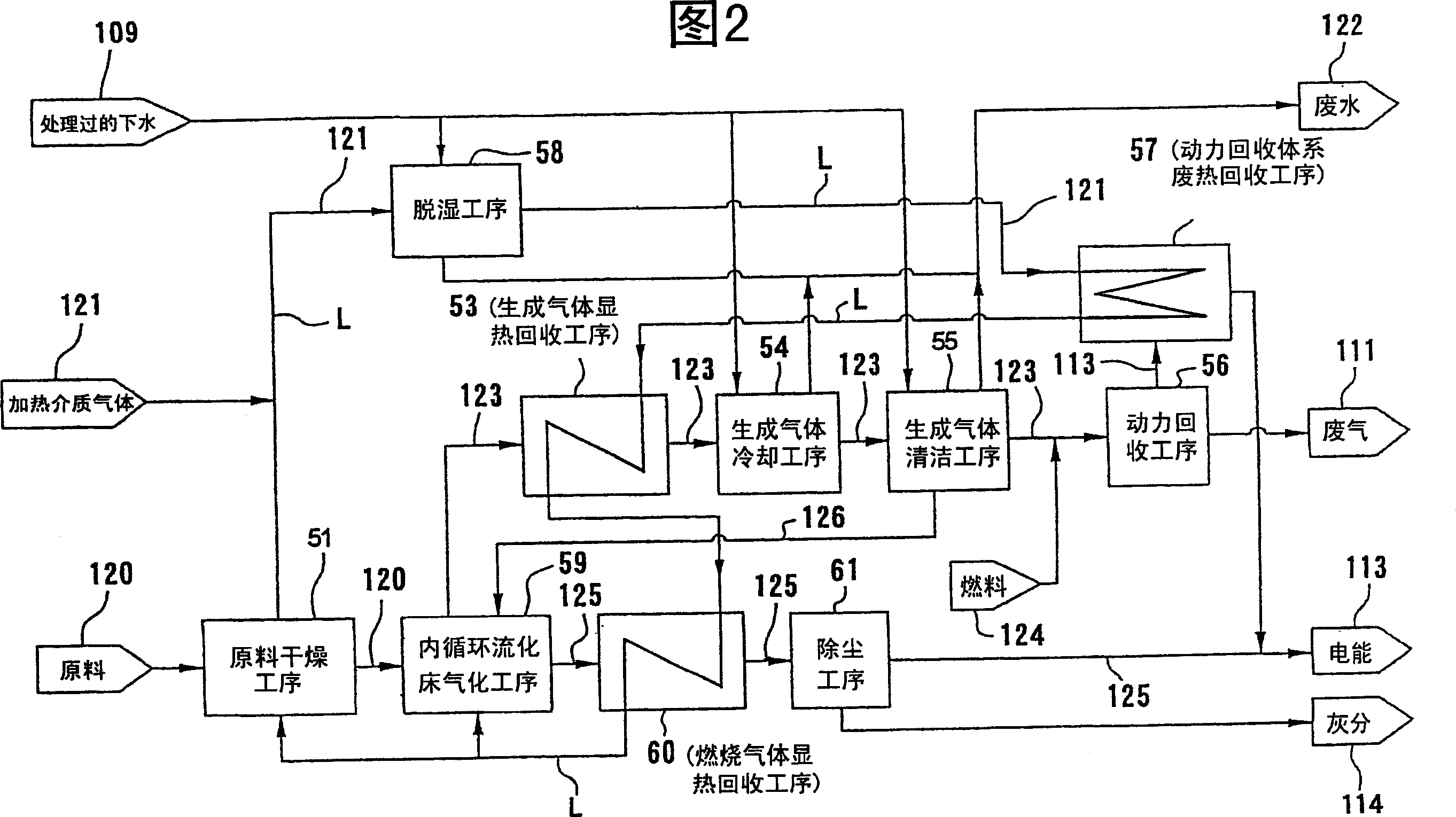

[0058] figure 1 Shown is the basic system arrangement of a treatment plant for carrying out the method for treating organic matter with a high water content according to the invention. like figure 1 As shown in , the treatment device has a raw material drying process 51 for drying sewage sludge containing high water content organic matter, a pyrolysis and gasification process 52 for pyrolysis and gasification of dried organic matter, and a process for A produced gas sensible heat recovery process 53 for recovering sensible heat from the produced gas generated by pyrolysis of organic substances, a produced gas cooling process 54 for cooling the produced gas, a produced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com