Boiler using gas or fuel oil

An oil-fired boiler and gas technology, applied in the field of combustion equipment boilers, can solve the problems of low boiler thermal efficiency and high nitrogen oxides, and achieve the effect of avoiding excessively high volume heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

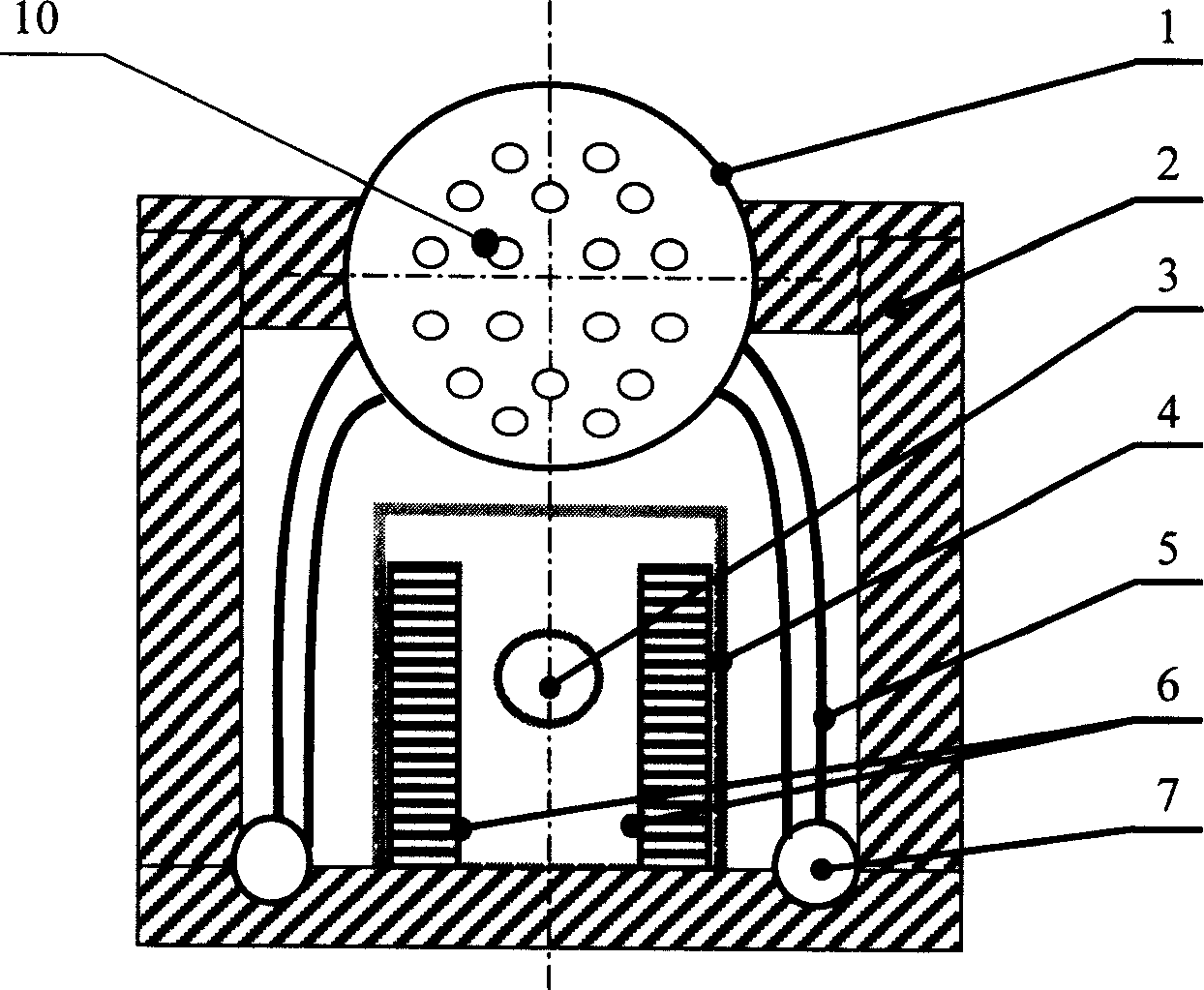

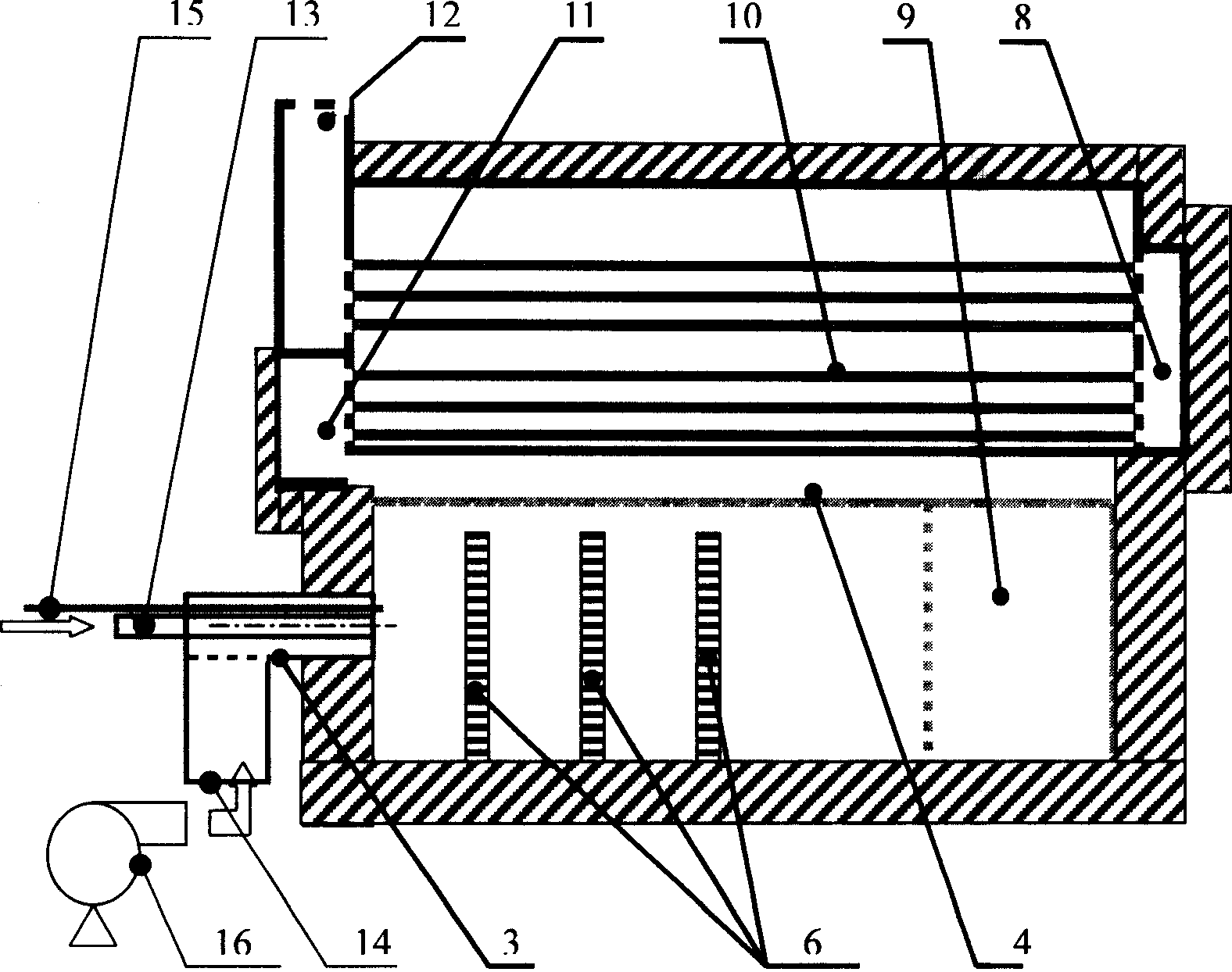

[0015] In this embodiment, refractory materials are laid on the bottom of the boiler body, surrounded by refractory furnace walls 2; a cylindrical drum 1 is erected above the boiler body, and the upper half of the drum is provided with a main steam valve, an auxiliary steam valve, a safety valve, and a safety valve respectively connected by pipelines. Valve, water level gauge and pressure gauge, the upper half of the outer front end of the drum is connected with the flue gas outlet 12, the lower half is connected with the front smoke box 11, the rear end is connected with the rear smoke box 8, and the inside of the drum is along the axis direction Arrange the upper and lower groups of smoke pipes 10, the lower set of smoke pipes 10 are respectively connected to the front smoke box 11 and the rear smoke box 8, and the upper set of smoke pipes are respectively connected to the rear smoke box 8 and the smoke outlet 12; A drain pipe is led out obliquely downward on both sides respe...

Embodiment 2

[0021] In this embodiment, a traditional coal-fired boiler is transformed, and a combustion stirring reactor is installed in the furnace, and the fuel air supply device is designed according to the furnace load, so that it becomes a boiler of the present invention capable of burning gas or liquid fuel.

[0022] The structure of the traditional coal-fired boiler used is: the boiler body is surrounded by a refractory furnace wall 2, the upper drum 1 is erected above, and the smoke pipe is arranged inside the upper drum 1, and the upper half of the upper drum 1 is respectively connected to the steam boiler by pipes. Valves, safety valves, water level gauges and pressure gauges extend downward from the lower half of the upper drum 1 to connect to the lower drum, where a part of the water pipes are attached to or embedded in the furnace wall 2 to form a radiant heating surface—— The water-cooled wall, the lower drum is placed at the bottom of the boiler, and a sewage valve is installe...

Embodiment 3

[0026] In this embodiment, three pieces (6 pieces in total) of regenerators 6 are separately placed on the bottom of the combustion stirring reactor against the two side walls of the combustion chamber. The shape is cuboid, the height of each regenerator accounts for 80% of the combustion chamber height, the length accounts for 8% of the combustion chamber length, and the width accounts for 10% of the combustion chamber width; after setting the regenerator in the combustion stirring reactor, due to It assists the wall of the hot combustion stirred reactor to conduct a strong heat exchange with the mixed gas, so the temperature distribution is more uniform, and it helps the stirring and mixing of the gas inside the combustion stirred reactor.

[0027] Other parts are identical with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com