Combustion chamber of internal combustion engine

A technology of combustion chamber and internal combustion engine, which is applied in the field of combustion chamber and can solve the problems of residual exhaust gas, exhaustion, residual exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

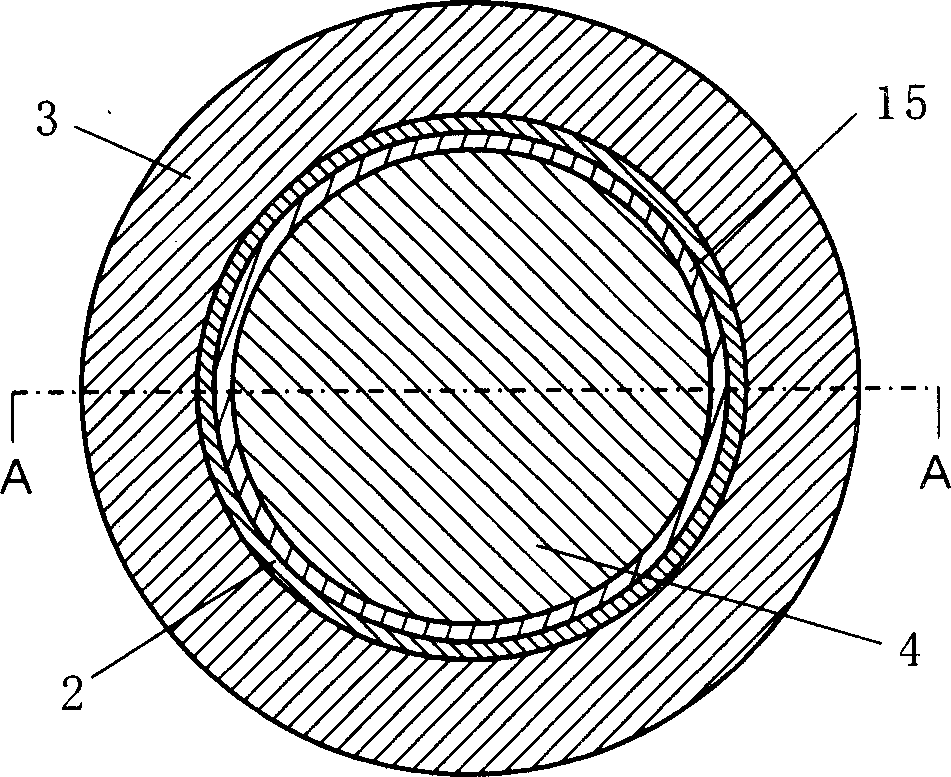

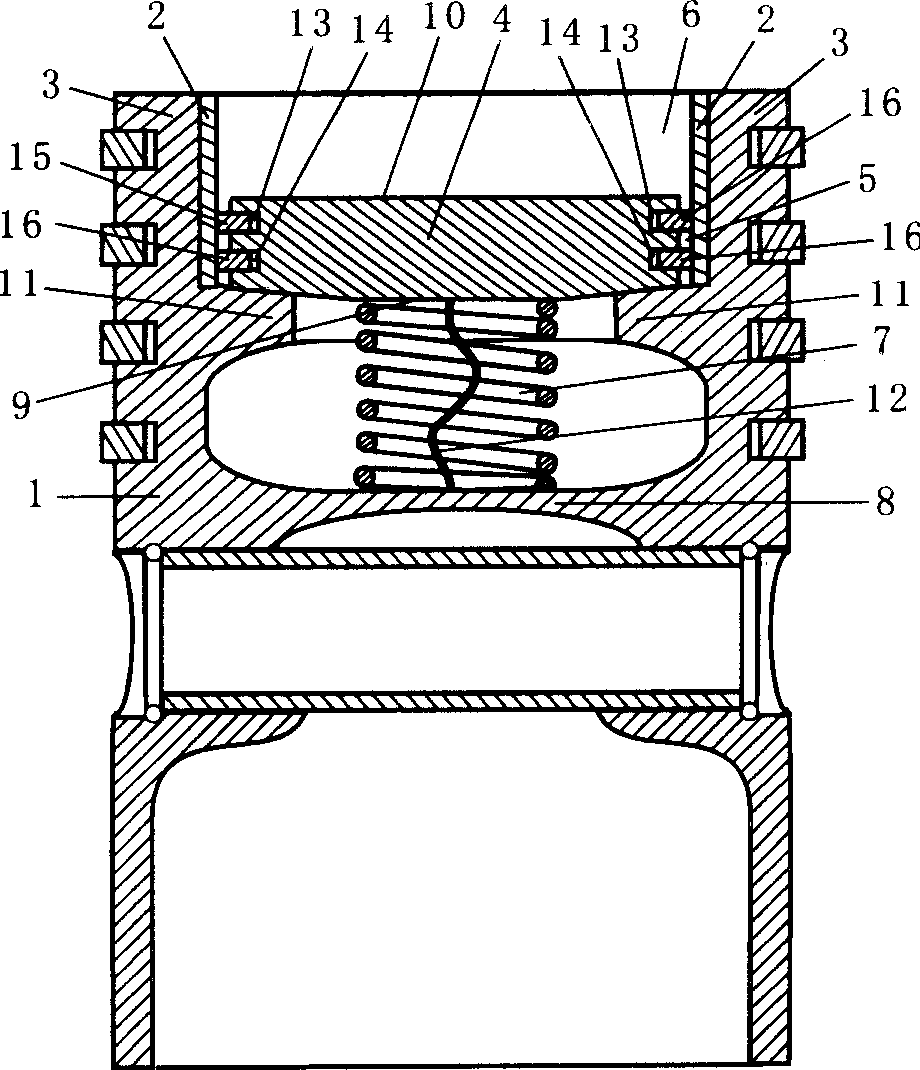

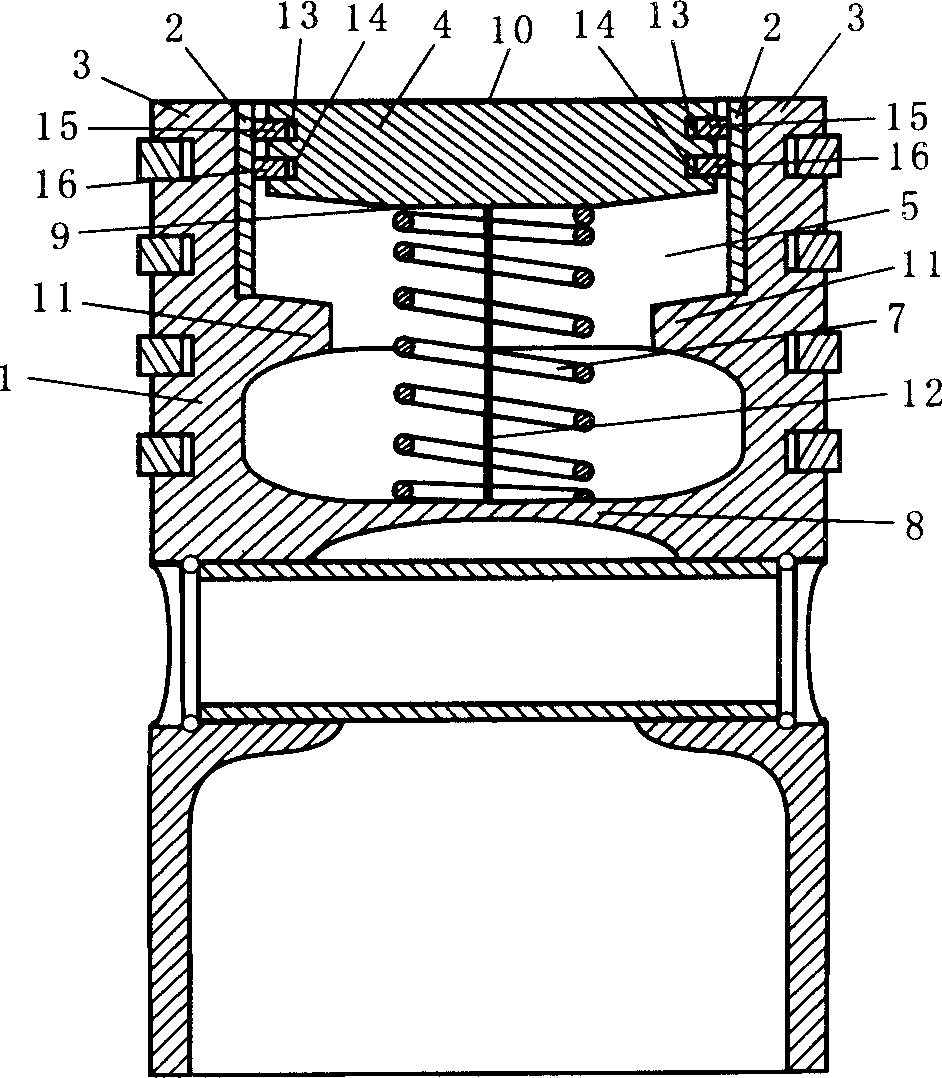

[0019] Depend on figure 1 The cylinder piston plan view and figure 2 The top of the cylinder piston shown along the figure 1 It can be seen from the side cross-sectional view of line A-A in the middle that the top of the cylinder piston 1 head is an annular combustion chamber wall body 3, and this annular combustion chamber wall body 3 forms a concavity-shaped (obviously also cylindrical) concave cavity 5, figure 2 The concave space formed by the annular combustion chamber wall body 3 and the conical combustion chamber piston 4 is exactly a unified combustion chamber 6. The combustion chamber piston 4 is made of aluminum alloy or other heat-resistant metal materials. The bottom surface 9 of the combustion chamber piston 4 is externally provided with a spring 7, one end of the spring 7 is connected to the bridge structure 8 connected to the pin seat of the cylinder piston 1, and the other end is supported or connected to the bottom surface 9 of the combustion chamber piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com