Bus-stop sign

A technology for buses and stop signs, applied to signs, instruments, display devices, etc., can solve problems such as high cost, heavy weight, and corrosion resistance, and achieve improved bending section modulus, improved bending resistance, and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

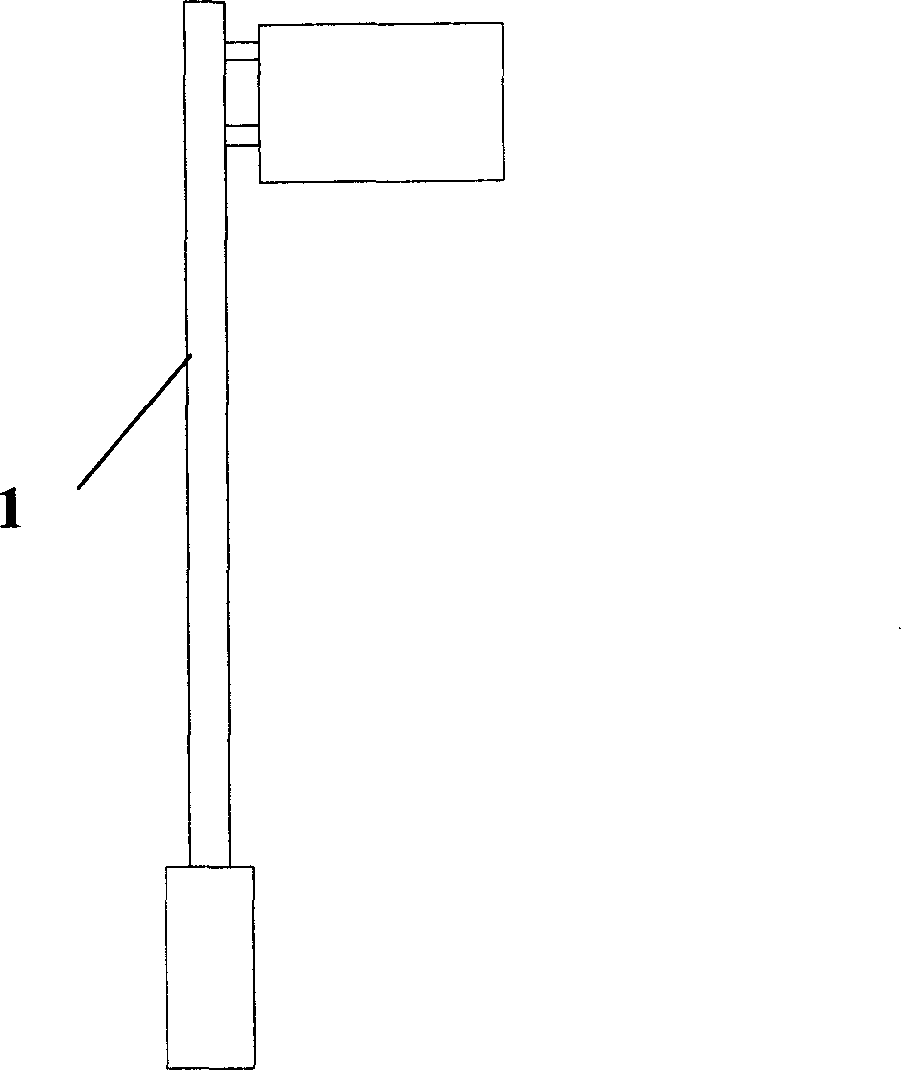

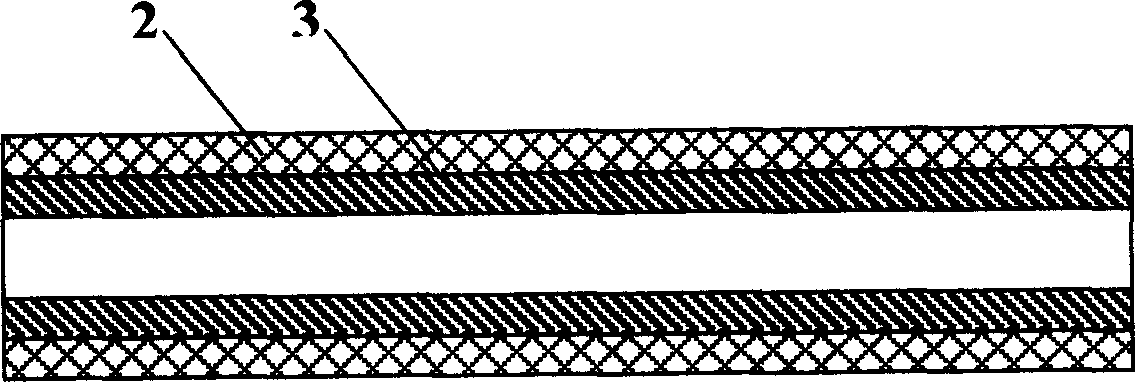

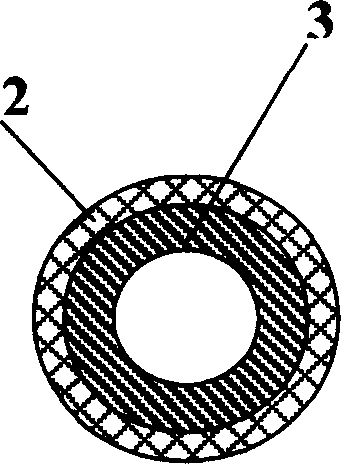

[0011] As shown in Fig. 1, Fig. 2 and Fig. 3, a bus stop sign of the present invention is composed of at least one tubular member 1, and at least one signboard is arranged on said tubular member 1, wherein any one The said tubular members 1 are respectively made of stainless steel tubes 2, any one of said stainless steel tubes 2 is provided with reinforced fiber plastic tubes 3, the diameter of said reinforced fiber plastic tubes 3 is the same as said The diameters of the stainless steel pipe body 2 match, and the stainless steel pipe body 2 and the reinforced fiber plastic pipe body 3 are fixedly connected.

[0012] Further, the radial section of the tubular member 1 is circular, or rectangular, or square, or has a special-shaped section.

[0013] Further, the tubular members 1 are connected by a welding structure or a riveting structure.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap