Solid-liquid centrifugal separator of leached and extracted coupling resultant

A technology of coupled reaction and centrifugal separation, applied in centrifuges with rotating drums, centrifuges, etc., can solve the problems of organic solvent loss, easy introduction of impurities, complicated centrifugal filtration and separation operations, etc., to reduce losses and avoid environmental pollution Pollution, the effect of solving economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] centrifugation

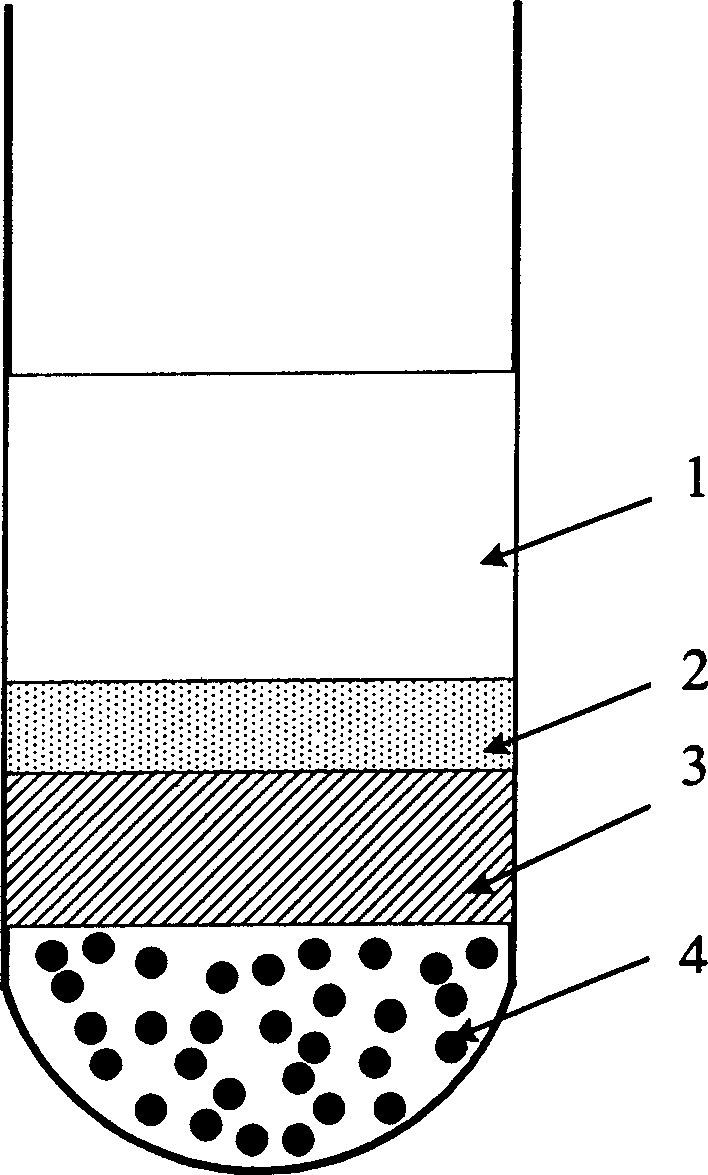

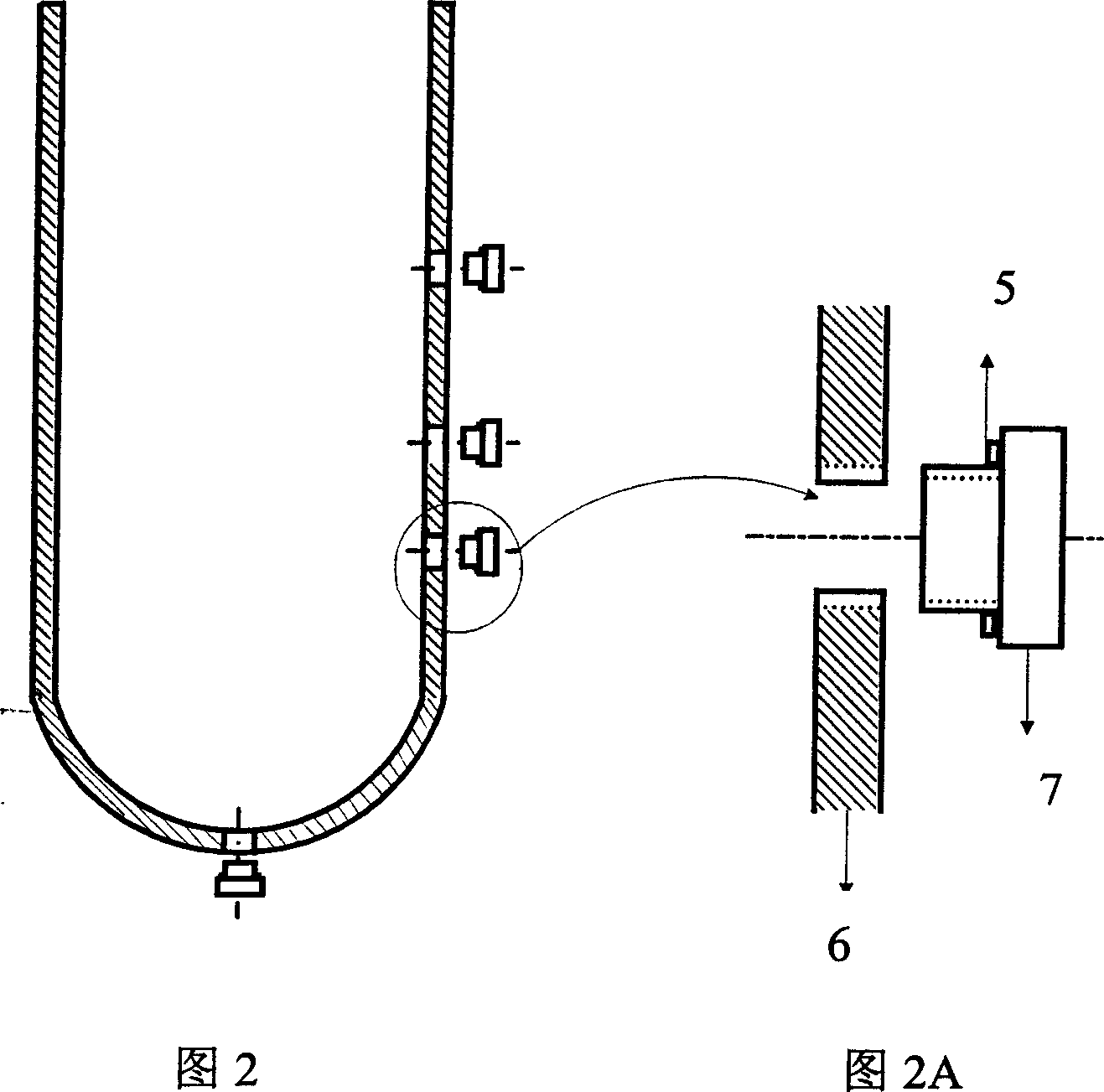

[0038] Please refer to FIG. 2 and FIG. 2A. On the tube wall of a 250ml centrifuge tube of a centrifuge, there are 3 round holes with internal thread, (the position of the tube wall opening: 1.0cm, 1.6cm, 2.0cm from the bottom of the tube). A round hole with an internal thread is opened at the bottom of the centrifuge tube, and each round hole is equipped with a sealing plug with a screw buckle. Add 10g of mineral (zinc concentrate), 10ml of organic solvent (tetrachlorethylene), and 100ml of leaching solution (composed of 2mol / L sulfuric acid and 0.2mol / L nitric acid) into a 250ml reaction kettle. Close the reaction kettle, turn on the stirring and heating device, and when the temperature reaches 80°C, pass O 2 , and maintain O 2 The pressure is 0.1 MPa, and the reaction takes 3 to 6 hours. After the reaction, the leached ore pulp was quickly poured into the device of the present invention, and separated by centrifugation (as shown in Figure 2 and Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com