Gas calibration method for semiconductor equipment

A semiconductor and gas technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc., can solve the problems of long calibration time, high cost, and limited cost, and achieve large calibration range and low cost , Calibration fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

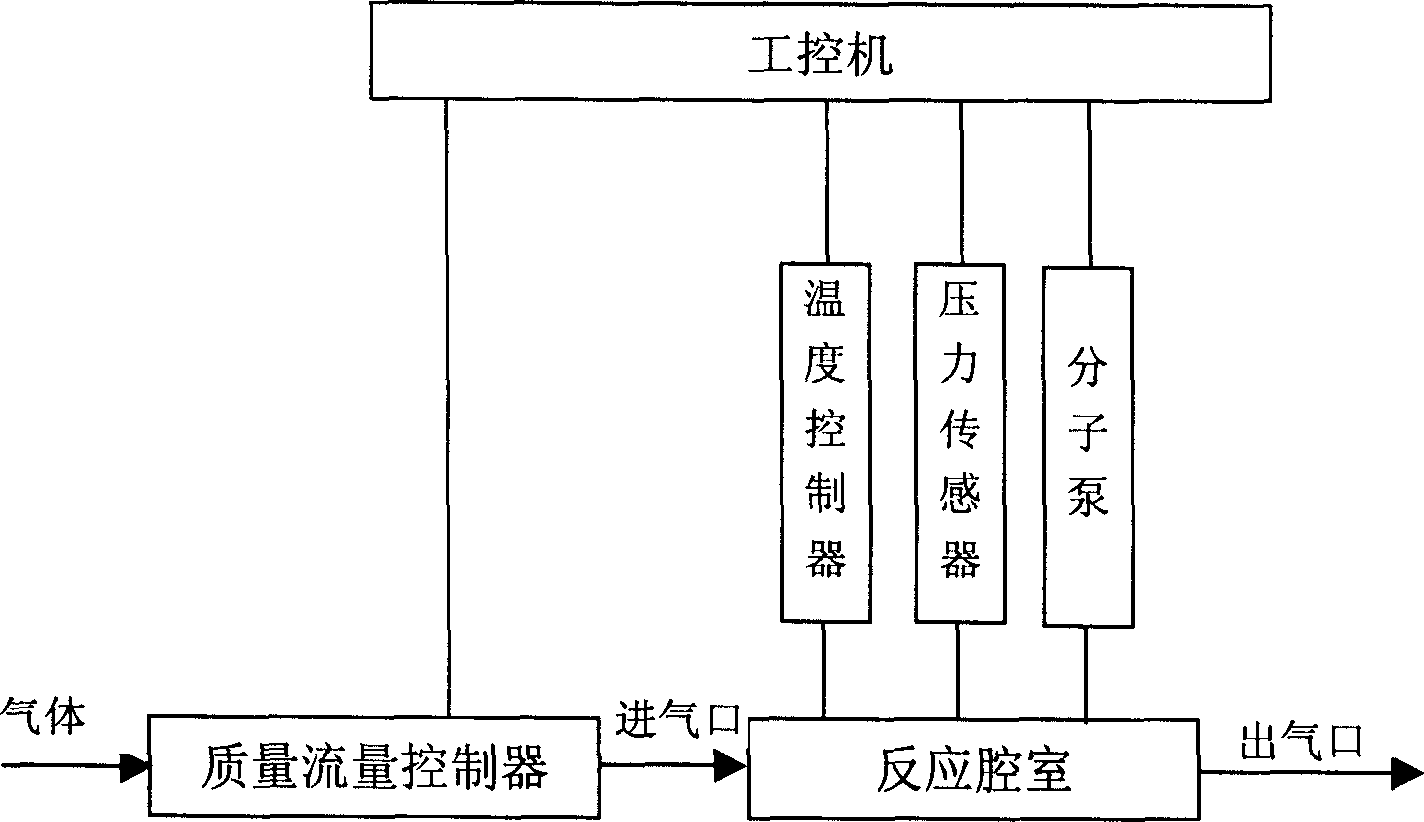

[0018] Hardware connection structural diagram of the present invention, as figure 1 shown. The gas enters the chamber from the air inlet of the reaction chamber through the mass flow controller, and the mass flow controller, temperature controller, pressure sensor, and molecular pump are connected to the industrial computer, and the gas calibration program runs on the industrial computer.

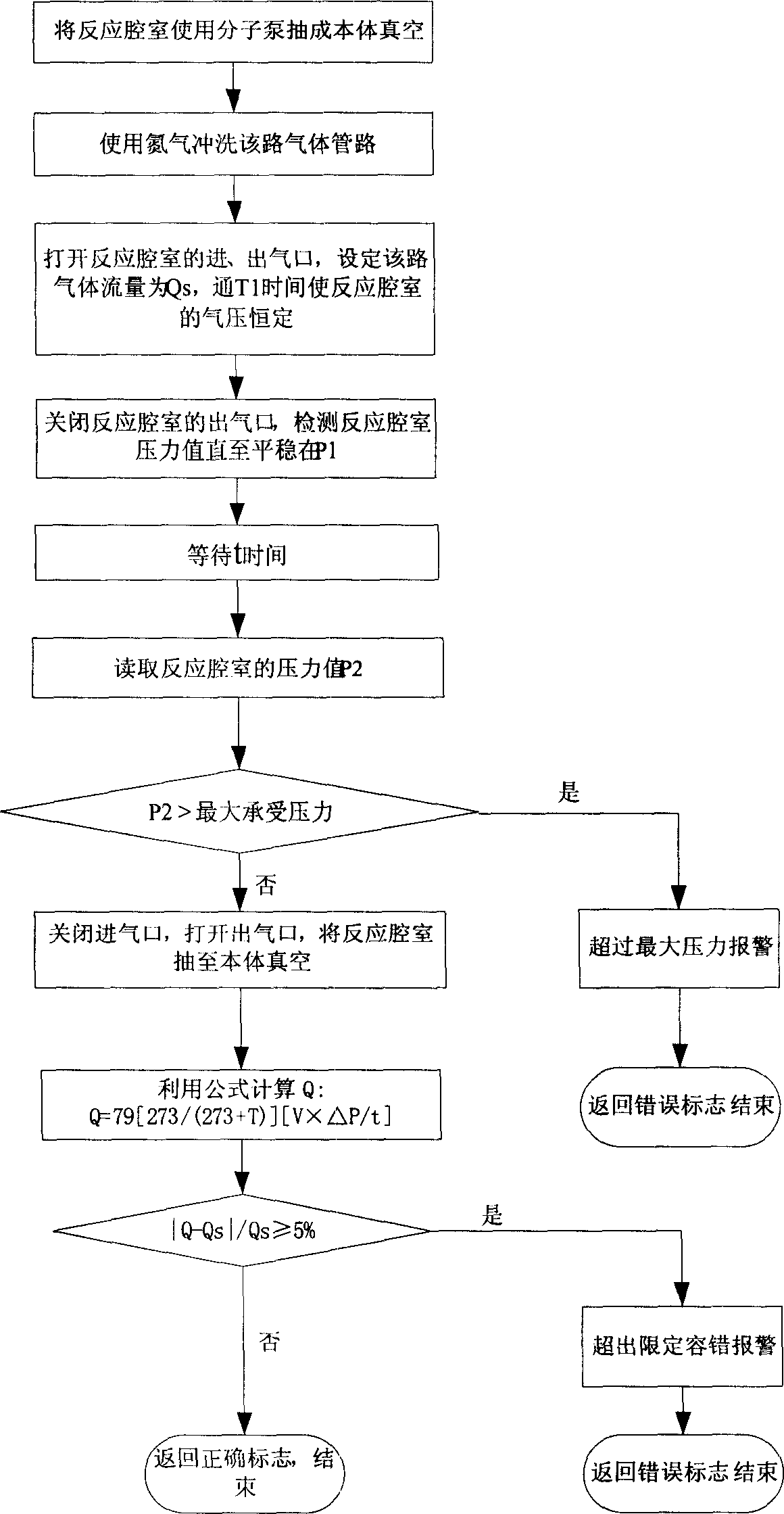

[0019] The program flowchart of the present invention, as figure 2 shown. First, use a molecular pump to evacuate the reaction chamber to a general vacuum, and use nitrogen to flush the gas pipeline, open the gas inlet and outlet of the reaction chamber, and set the gas flow rate of this path to Qs (unit: sccm).

[0020] Close the gas outlet of the reaction chamber, and detect the pressure value of the reaction chamber until it stabilizes at P1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com