Laser beam space pose calibration method for non-orthogonal axis laser total station

A non-orthogonal axis and laser beam technology, which is applied in the direction of instruments, measuring instruments, and optical devices, can solve the problems of laser beams being fixed and moving frequently, so as to expand the calibration range, meet a wide range of applications, and coordinate space points Measuring Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

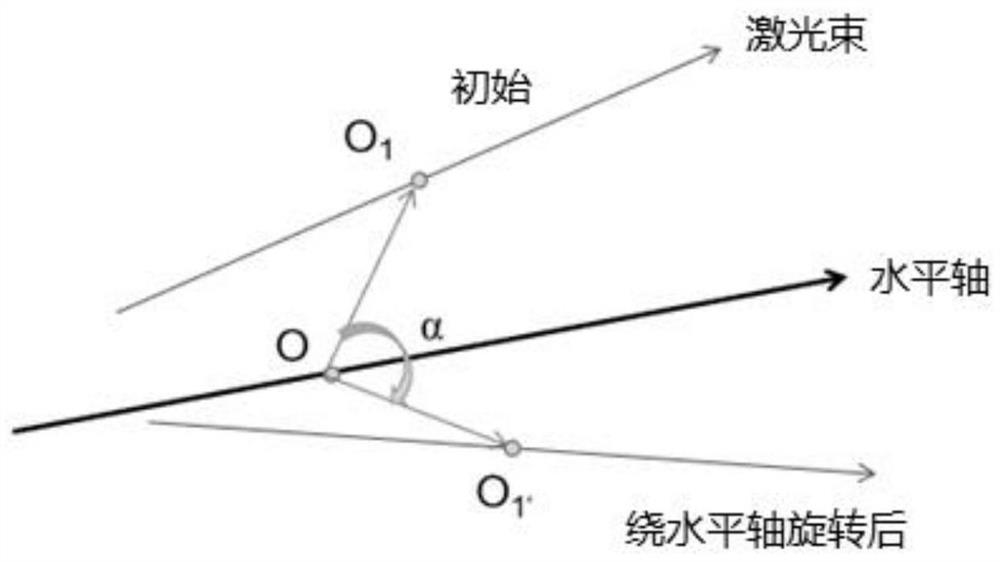

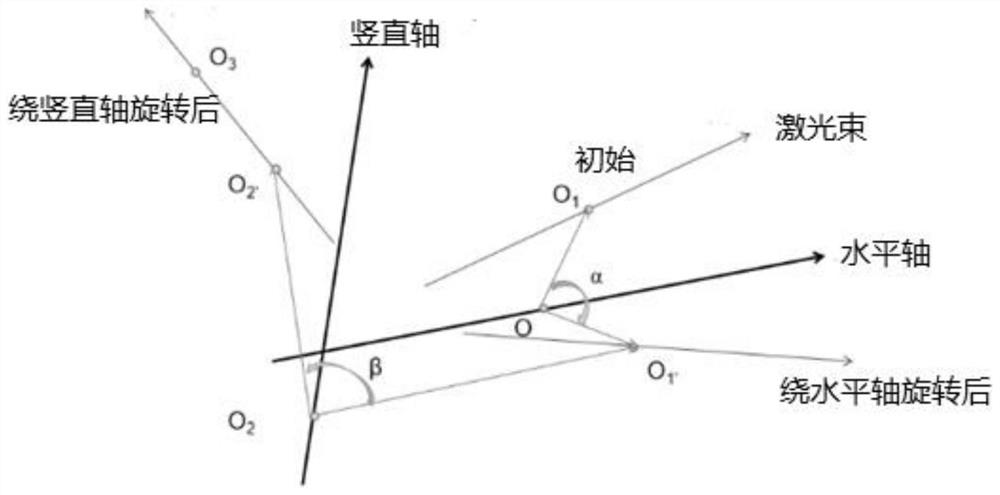

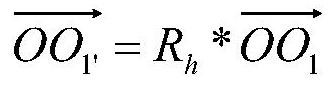

[0036]The laser beam pose calibration method based on machine vision in large-scale space proposed by the present invention uses the horizontal axis and vertical axis parameters of the high-precision two-dimensional turntable that has been calibrated to drive the high-precision two-dimensional turntable to drive the The laser rotates in space, using the fixed point and direction vector on the horizontal and vertical axes of the two-dimensional turntable as a reference, the direction vector and coordinates of the laser beam and the fixed point on it after rotation are obtained, and finally fitted by least squares Algorithm to calculate the spatial pose of the laser beam.

[0037] The pose calibration system of the laser beam in a large-scale space is mainly composed of a high-precision two-dimensional turntable, a laser to be calibrated, a 5 million industrial camera, a laser tracker, a reflective hollow target ball and a hemispherical target. Among them, the reflective hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com