Manufacturing method of reflective layer of display device, reflective LCD device and transflective lcd device

A semi-transmissive, semi-reflective, liquid crystal display technology, applied in static indicators, instruments, nonlinear optics, etc., can solve the problems of damaged pixels and bright spots of liquid crystal displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in more detail with reference to the following drawings. However, the embodiments of the present invention have many different forms and are not limited to the embodiments described below. In addition, the provided embodiments will disclose the present invention fully and in detail, and fully convey the spirit of the present invention to anyone skilled in the art. Labels on the figures correspond to corresponding components.

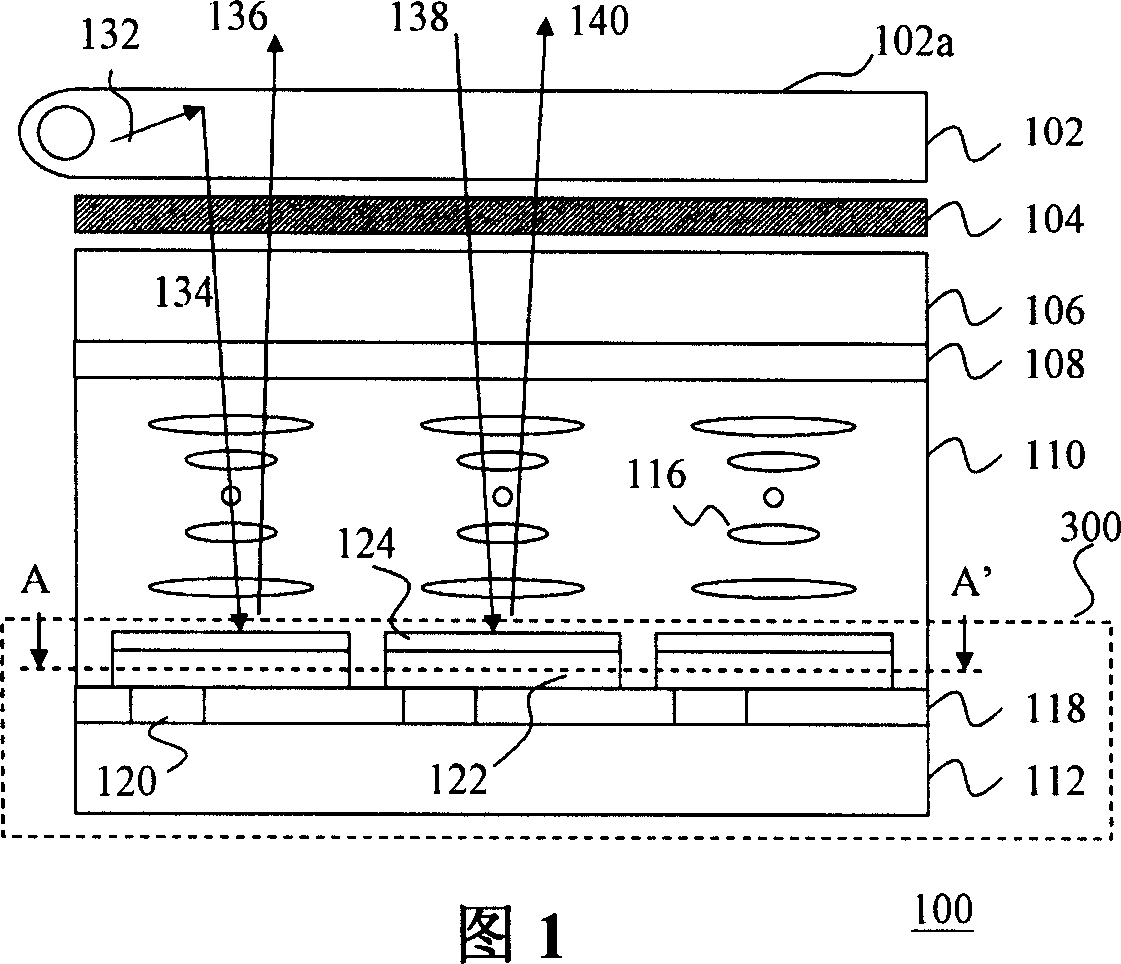

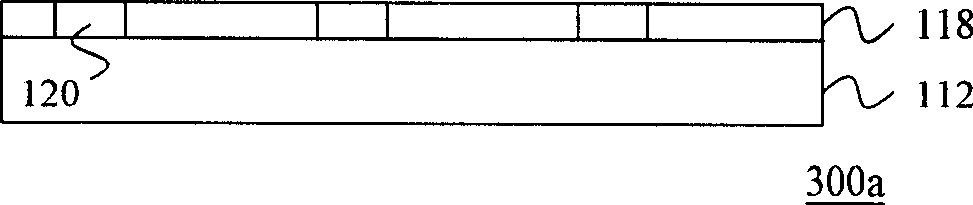

[0053] FIG. 1 is a schematic cross-sectional view of a reflective liquid crystal display according to an embodiment of the present invention. Please refer to FIG. 1, a reflective liquid crystal display 100 includes a light source module 102, a polarizer 104, a first substrate 106, a first light-transmitting electrode 108, a liquid crystal layer 110 including a plurality of liquid crystal display molecules 116, a second substrate 112, a reflective layer 122 and a protective layer 124 formed on the reflectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com