Woody material and its surface processing method

A technology of wooden materials and processing methods, which is applied in the processing of the surface of wooden materials, and the processing of cylindrical and other shapes of wood. It can solve the problems of affecting the service life of the board, monotonous decorative effect, unfavorable paint firm adhesion, etc., and achieve enhanced sound absorption. Sound insulation function, good anti-skid function, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for processing the surface of a wooden material, specifically a method for processing a wooden floor, comprising the following steps:

[0024] S1: After the logs are cut and shaped, they are dried in a drying kiln to avoid deformation of the wood while it is naturally drying; Splicing groove and anti-deformation bottom groove; the surface is preliminarily sanded to a certain degree of flatness, and the floor blank is made;

[0025] S2: On the surface of the floor blank obtained in step S1, use a high-speed rotating steel wire brush to scrape it several times to scrape off a layer of wood fiber on the soft part, so that the surface of the floor blank forms a convex-concave pattern, and the soft part is the original soft part In the wood grain part, the convex-concave pattern formed is compatible with the original wood grain pattern of the wood;

[0026] After step S2, the surface of the floor blank is polished, and then the painting process is carried out. In t...

Embodiment 2

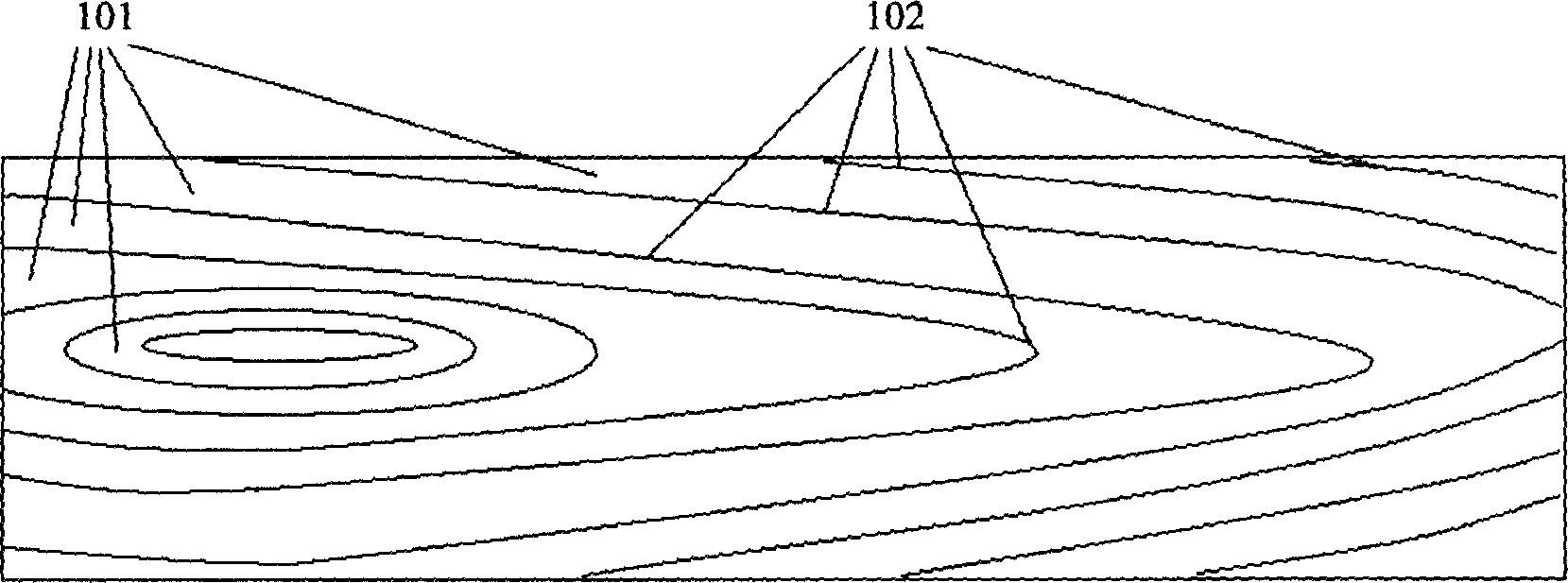

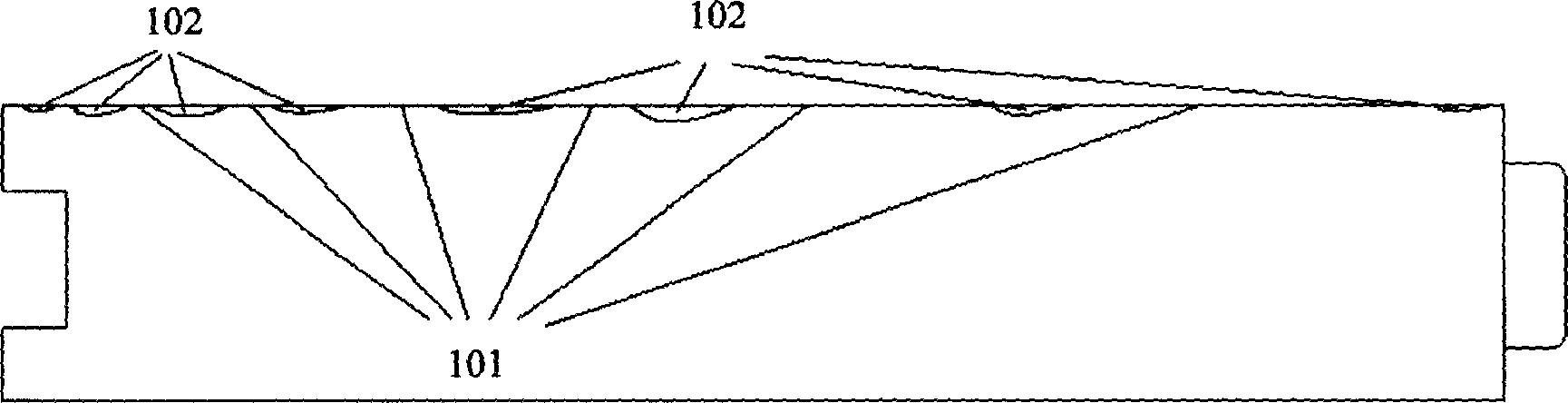

[0029] Such as figure 1 and figure 2 As shown, a wooden material, specifically a wooden floor, is provided with a convex 101 and a concave 102 on its surface, the convex 101 is arranged on the original hard wood grain part of the wood, and the concave 102 is arranged on In the original soft wood grain part, the pattern formed by the convex 101 and the concave 102 is consistent with the original wood grain pattern of the wood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com